Vibrant designs with DTF transfers have quickly become the go-to method for anyone looking to create eye-catching apparel. This innovative Direct-to-Film printing technique allows for the reproduction of intricate details and bold colors that stand out on various types of fabrics. Whether you’re a DIY enthusiast or an established business owner, utilizing DTF transfers can elevate your custom apparel designs, making them more appealing and professional. In this tutorial, we will guide you through the essential heat transfer techniques needed to achieve stunning results. From design preparation to proper application, you’ll learn the secrets to printing vibrant colors that truly capture the essence of your creativity.

Embracing the world of apparel customization has never been easier with cutting-edge film transfer methods. The process of transferring designs onto textiles using specialized film not only offers exceptional clarity but also vibrant color reproduction, making your creations pop. Perfect for artists and entrepreneurs alike, this approach revolutionizes the crafting of personalized clothing. In this guide, we will explore a comprehensive DTF transfer tutorial, detailing the necessary steps to ensure your designs inspire and captivate. Join us as we delve into these advanced printing techniques that unlock your full creative potential.

Mastering DTF Printing Techniques for Custom Apparel

Direct-to-Film printing (DTF) has emerged as a game changer for custom apparel makers, enabling the production of intricate designs with vibrant colors. Learning how to effectively use DTF transfer techniques can significantly enhance your apparel game, whether you’re creating designs for personal use or to fulfill customer orders. With DTF technology, the transfer of designs to fabrics is not only efficient but also produces stunning results that last through multiple washes.

Many people find DTF printing approachable due to its straightforward processes. From selecting the right materials to adjusting printer settings for optimal output, mastering these techniques empowers both hobbyists and professionals. Implementing proper heat transfer techniques allows you to bring your custom designs to life, ensuring that each piece reflects quality craftsmanship and aesthetic appeal.

Choosing the Right Materials for DTF Transfers

One critical aspect of successful DTF transfers is selecting high-quality materials. This includes DTF transfer papers that work seamlessly with your printer and the fabric types you plan to use. Investing in reliable brands ensures that your vibrantly designed prints adhere well to the intended substrates, whether cotton, polyester, or blends. The longevity of the vibrant designs largely depends on the base materials, so careful selection is paramount.

In addition to transfer papers, it’s equally important to consider the ink used in the printing process. Pigment-based inks are recommended for their vibrancy and durability, making them perfect for a variety of clothing items. Ensuring that all materials are compatible with one another leads to a smoother application process and enhances the overall quality of your custom apparel designs.

Step-by-Step Guide to DTF Transfer Application

To achieve optimal results with DTF transfers, it’s crucial to follow a detailed application process. Begin by preheating your fabric to eliminate moisture, a step that’s often overlooked but essential for creating a solid bond. Proper heat transfer application requires precision; placing the transfer correctly and ensuring even heat distribution during pressing can greatly affect the final output of your vibrant design.

Once the transfer has been positioned accurately, use a heat press set to the correct temperature and pressure for the recommended time. This method allows for the even melting of the adhesive, leading to a strong attachment of your vibrant design to the fabric. After cooling, carefully peeling off the transparent film reveals the finished product, showcasing your artistic vision with professional quality.

Essential Printer Settings for Optimal DTF Results

Setting up your printer properly is a crucial step towards achieving vibrant colors in your DTF transfers. Pixelation and discoloration can occur if you fail to adjust your printer settings appropriately. Ensuring that your printer uses pigment-based inks and is set to the highest quality will elevate the outcome of your designs significantly. Adjusting these settings can make a noticeable difference in how your final product looks.

Furthermore, operating within the correct color profile, specifically CMYK, is vital for maintaining color accuracy. This ensures what you see on your screen will be what you get when printed. Any deviations could lead to disappointments, so taking the time for these adjustments can enhance the quality of your custom apparel designs while reducing waste and reprints.

Post-Transfer Care to Maintain Vibrancy

Once you’ve successfully applied your DTF transfer, the next step is ensuring that your designs remain vibrant for as long as possible. Proper post-transfer care is key; advising customers on washing in cold water and avoiding harsh chemicals will help prolong the life of the graphic. Fabrics can degrade and colors can fade if not treated correctly, so sharing these tips can greatly enhance customer satisfaction.

Another crucial aspect of maintaining the quality of your designs involves ironing techniques. Educating users to iron on the reverse side minimizes any potential damage to the vibrant print, preserving its appearance over time. By instilling these care guidelines, you can ensure that your custom apparel maintains its fresh look and high quality, ultimately leading to repeat customers and glowing reviews.

Exploring DTF Transfer Benefits for Creatives

The advantages of DTF transfers go beyond mere aesthetics; they revolutionize the customization process for creators and businesses alike. DTF technology offers incredible flexibility to produce intricate designs that traditional methods may struggle with. This means that whether you’re designing small runs or larger bulk orders, DTF printing can accommodate a variety of custom apparel needs.

Additionally, one of the significant benefits of DTF transfers is the time efficiency it brings to the production process. As users sharpen their skills and learn more about effective techniques, they can produce stunning garments faster without sacrificing quality. This allows for a more productive workflow and maximizes opportunity for creativity—one can quickly transfer vibrant designs to fabric while experimenting with new ideas.

Frequently Asked Questions

What are the benefits of using vibrant designs with DTF transfers?

Vibrant designs with DTF transfers allow for high-quality prints that showcase colors in detailed, vivid representations. The DTF printing method offers excellent durability, flexibility in applying complex designs, and compatibility with various fabrics, making it a preferred choice for custom apparel designs.

How do I create vibrant designs with DTF transfers?

To create vibrant designs with DTF transfers, begin with high-resolution images and prepare your design using graphic software set to the CMYK color profile. After printing your design in reverse on DTF film, apply hot-melt adhesive powder and use a heat press for transfer, ensuring great quality and vividness.

What materials do I need for vibrant designs with DTF transfers?

For achieving vibrant designs with DTF transfers, you’ll need quality DTF transfer paper, compatible pigment-based inks, and a reliable heat press. Choosing the right materials is essential for producing bright colors and ensuring effective adhesion to various fabric types.

Can I use a regular printer for DTF transfers?

No, to achieve vibrant designs, you should use a printer equipped for DTF printing. Printers with pigment-based inks, like the Epson EcoTank, are recommended to best capture the bright colors and details essential for successful DTF transfers.

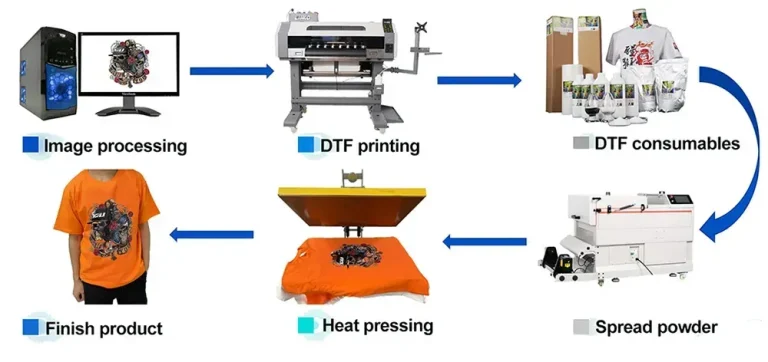

What are the key steps in a DTF transfer tutorial for vibrant designs?

A DTF transfer tutorial for vibrant designs includes: 1) Design preparation in graphic software, 2) Material selection (transfer paper and inks), 3) Printer settings adjustment, 4) Printing designs in reverse, 5) Applying adhesive and using a heat press, and 6) Post-transfer care to maintain vibrancy.

How do I care for garments printed with vibrant designs using DTF transfers?

To maintain the vibrancy of DTF transfer prints, wash garments in cold water and avoid bleach. It’s best to air dry and if ironing is necessary, do so on the reverse side to preserve the quality of the vibrant designs.

| Step | Description | Tips |

|---|---|---|

| 1. Design Preparation | Create and prepare your design for printing. | Use graphic design software and CMYK color profile. |

Summary

Vibrant designs with DTF transfers can be achieved by following a detailed and methodical approach to the printing process. This innovative technique allows for the transfer of high-quality, eye-catching designs onto a variety of fabrics. The process begins with design preparation using professional software and correct color settings, ensuring clarity and vibrancy. Next, choosing the right materials such as quality transfer paper and pigment-based inks is crucial.

Once your design is ready, printing requires attention to detail like reversing the image and applying hot-melt adhesive powder to achieve a durable bond. After printing, proper transfer application through heat pressing is essential to firmly set the design onto the garment. Finally, caring for the vibrant design post-transfer—by following specific washing and ironing guidelines—ensures longevity and maintains the eye-catching quality of your creations. With these comprehensive steps, anyone can unlock the full potential of vibrant designs through DTF transfers, turning creative visions into reality.