In the ever-evolving landscape of printing technology, UV DTF technology—short for Ultra Violet Direct-to-Film—has emerged as a game changer, merging the precision of UV printing with the flexibility of direct-to-film techniques. This innovative solution stands out by producing durable prints that can maintain their vibrancy on various substrates including textiles, wood, and metals. As businesses and consumers alike seek more cost-effective and high-quality custom printing options, UV DTF technology offers a promising avenue for achieving eye-catching designs without compromising longevity. With its ability to generate vivid colors and intricate details, this method not only meets but exceeds modern demands for quality in the printing sector. Join us as we explore the multifaceted benefits and applications of this groundbreaking printing technology that continues to redefine the standards of excellence in the industry.

When discussing contemporary printing solutions, terms like UV direct-to-film technology or ultraviolet DTF methods come to the forefront as synonymous expressions describing a cutting-edge approach to custom printing. These alternatives highlight the main features of this advanced technique, which includes a unique fusion of UV printing benefits and direct-to-film processes. The allure of such printing methods lies in their adaptability to a wide range of materials, their ability to produce robust and detailed visuals, and their eco-friendly ink options. By utilizing advanced technology, businesses are empowered to create personalized items that not only stand out but also sustain their quality over time. Thus, understanding the nuances of UV DTF technology and its various terminologies is essential for anyone looking to leverage the advancements in modern printing.

Understanding the Mechanism of UV DTF Technology

UV DTF technology employs a unique printing mechanism that captures the essence of modern printing standards. This process utilizes ultra-violet light to cure inks on a specially formulated heat transfer film, enabling designs to be applied to almost any surface with incredible precision. By leveraging the advantages of both UV printing and Direct-to-Film methods, UV DTF technology opens the door to a diverse array of applications, from promotional materials to custom apparel and beyond.

The precision of the UV DTF process lies in its step-by-step execution, which begins with a digital design programmed into the printer. Once printed onto the film, the design undergoes curing with UV light, providing an instant, robust adhesion of ink to the material. This aspect not only accelerates the production timeline but also guarantees vibrant colors and intricate details that are exceptionally durable, showcasing the advanced capabilities of today’s printing technology.

The Advantages of UV Printing and Direct-to-Film Techniques

UV printing, when combined with Direct-to-Film techniques, presents several substantial advantages that elevate the quality of outputs. Notably, the inks used in UV DTF technology offer superior vibrancy and clarity, making them ideal for businesses that emphasize detailed graphics in their products. Moreover, the curing process through UV light ensures that colors remain consistent and resistant to fading, setting it apart from older printing methods.

In addition to aesthetic benefits, the longevity of prints produced through UV DTF technology cannot be overlooked. These prints are engineered to withstand scratches, UV exposure, and environmental factors, making them suitable for both indoor and outdoor applications. This durability translates into significant cost savings for companies, as they require less frequent reprinting, thus optimizing operational efficiency while maintaining high-quality standards.

Exploring the Versatility of UV DTF Technology

One of the standout features of UV DTF technology is its remarkable versatility. It allows for printing on both rigid and flexible substrates, making it suitable across a spectrum of industries—from fashion and promotional goods to decorative items and signage. This adaptability is crucial in today’s marketplace, where consumer preferences increasingly favor personalized and unique products.

Apart from traditional materials like textiles and plastics, UV DTF technology also excels in printing on unconventional surfaces such as wood, metal, and ceramics. This opening of possibilities enables companies to diversify their product offerings and meet unique customer demands, driving innovation and creativity in product design. As a result, businesses can foster growth by catering to niche markets that appreciate bespoke items.

Sustainability and Eco-Friendliness in UV DTF Production

In an era marked by environmental consciousness, the move towards sustainable printing practices becomes increasingly pivotal. UV DTF technology showcases its commitment to eco-friendliness through the use of eco-solvent inks, which drastically reduce harmful emissions and comply with stringent environmental regulations. These advancements in the printing process not only align with global sustainability goals but also appeal to eco-conscious consumers who prefer environmentally responsible products.

By integrating eco-friendly practices into the UV DTF production workflow, businesses not only enhance their brand image but also contribute to a sustainable future. This transition is vital as industries face growing pressure to adopt greener operations, ultimately leading to healthier ecosystems and improved corporate responsibility. As UV DTF technology continues to evolve, its ability to offer both exceptional quality and sustainability will undoubtedly shape the future of custom printing.

Optimizing Production with Cost-Efficiency through UV DTF

Cost-effectiveness remains a critical consideration in any printing strategy, and UV DTF technology stands out for its potential savings. Traditional printing methods often involve extensive material waste and lengthy production times, while UV DTF technology minimizes these challenges by maximizing efficiency. The quick curing times and ability to print in high volumes without sacrificing quality significantly reduce overall production costs.

Additionally, the automated features integrated into modern UV DTF printers facilitate streamlined workflows, limiting the need for extensive manual labor and further cutting expenses. By investing in UV DTF technology, businesses can achieve a favorable balance between high-quality outputs and operational efficiency, making it an attractive choice for printers looking to remain competitive in a cost-sensitive market.

Emerging Trends in UV DTF Printer Innovations

The realm of UV DTF technology is continually evolving, with major manufacturers investing heavily in innovative solutions that enhance usability and output quality. New printer models equipped with advanced features, such as faster print speeds and improved software integration, are emerging in the market. These innovations not only empower users to produce professional-grade prints but also make the technology more accessible to a broader range of businesses, including small to medium enterprises.

As industries embrace new trends, adaptation becomes crucial. The combination of software for design and print job automation streamlines the workflow and enhances productivity. Printers equipped with cutting-edge technology not only ensure consistent quality but also foster creativity and experimentation, enabling businesses to push the boundaries of design and printing capabilities. This dynamic growth in the UV DTF sector suggests a promising future for various applications, from customized consumer goods to intricate promotional products.

Frequently Asked Questions

What is UV DTF Technology and how does it work?

UV DTF Technology, or Ultra Violet Direct-to-Film printing, is a modern printing method that prints designs onto a special coated film, which is then cured using ultraviolet light. This curing process creates a strong bond between the ink and the film, allowing for vibrant and durable prints on various substrates such as textiles, wood, and metal.

What are the key benefits of using UV DTF Technology in custom printing?

UV DTF Technology offers multiple benefits for custom printing, including versatility in printing on rigid and flexible surfaces, unmatched durability that resists fading and scratching, vivid colors with high detail, and the availability of eco-friendly inks. Additionally, it is cost-effective due to reduced material waste and faster production times.

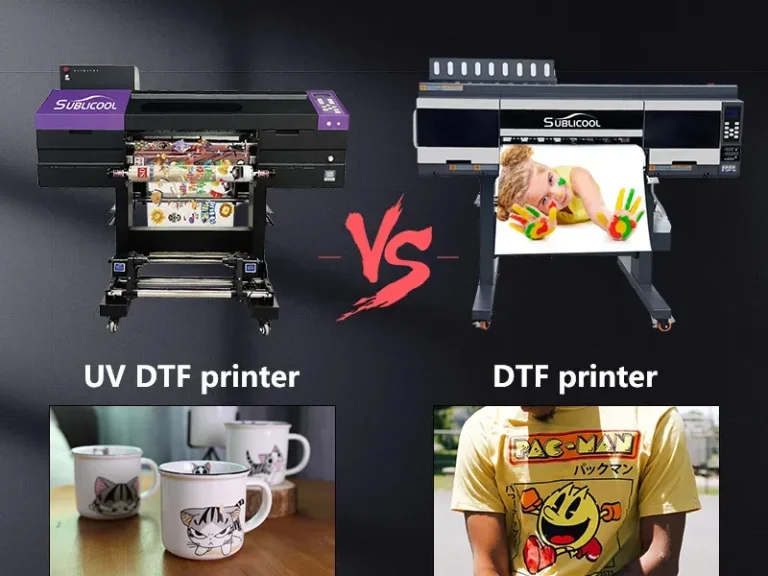

How does UV DTF compare to traditional DTF and UV printing methods?

UV DTF Technology combines the strengths of both traditional Direct-to-Film (DTF) and UV printing methods. Unlike traditional DTF, which may require additional heat processes, UV DTF uses UV light for instant curing. This results in faster turnaround times and greater durability compared to both methods, making it a premium choice for high-quality prints.

What materials can be printed using UV DTF Technology?

UV DTF Technology is incredibly versatile and can print on a variety of materials, including textiles, metal, wood, plastics, and cardboard. This makes it an ideal choice for a wide range of applications, from custom apparel and promotional items to home décor.

Is UV DTF Technology environmentally friendly?

Many UV DTF systems now utilize eco-solvent inks that are less harmful to the environment than traditional inks. These inks comply with strict environmental regulations, making UV DTF Technology a sustainable option for businesses looking to reduce their ecological footprint.

Can small businesses benefit from using UV DTF Technology?

Yes, small businesses can greatly benefit from UV DTF Technology as it is cost-effective, reduces waste during production, and allows for high-quality outputs. Its ability to produce customized and intricate designs quickly enables small enterprises to compete effectively in the market.

| Key Aspect | Details |

|---|---|

| Definition | UV DTF stands for Ultra Violet Direct-to-Film; a modern printing method that prints designs on a coated film, cured with UV light. |

| Process | Involves printing on a heat transfer film with ink that is cured almost instantaneously with UV light. |

| Versatility | Can print on rigid and flexible surfaces including textiles, wood, and metal. |

| Durability | Prints are resistant to fading, scratching, and UV exposure, extending product lifespan. |

| Color Quality | Excels in producing vivid colors and high detail for eye-catching visuals. |

| Eco-Friendliness | Utilizes eco-solvent inks that are less harmful and meet environmental regulations. |

| Cost-Effectiveness | Reduces material waste and improves production efficiency, making it financially sound. |

| Recent Developments | Innovative uses in home décor, custom apparel, and advancements in printer technology. |

Summary

UV DTF technology represents a significant advancement in the printing sector, merging the best elements of traditional methods with modern capabilities. Its versatility allows for creativity across various materials, while its durability ensures long-lasting results. The introduction of eco-friendly inks further emphasizes the technology’s relevance in today’s environmentally conscious market. Businesses aiming to enhance their efficiency and output quality should explore the benefits of UV DTF technology, as it opens up new avenues for innovative printing solutions. As consumer preferences shift towards customization and sustainability, incorporating UV DTF technology could be a game-changer in maintaining competitive advantage.