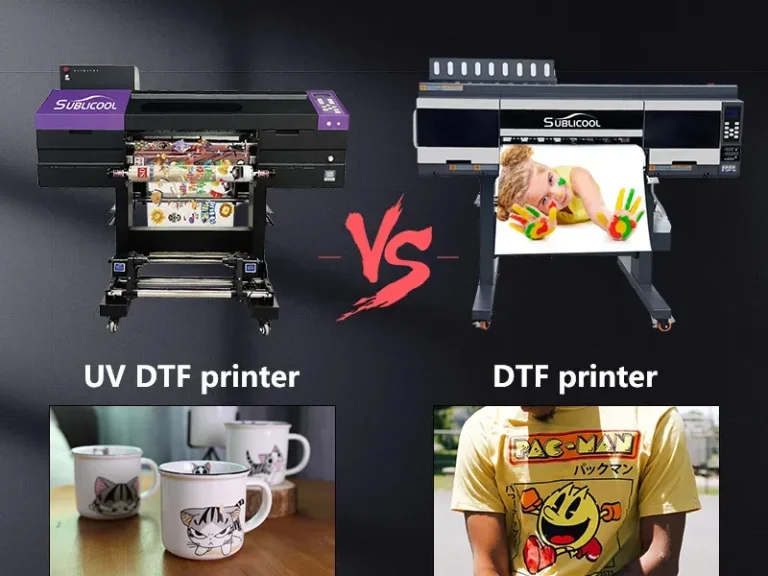

UV DTF printing has revolutionized the way we think about custom fabric printing and hard surface applications. This cutting-edge technology utilizes ultraviolet light to cure high-quality inks onto specially coated films, enabling vibrant colors and intricate designs that adhere to a variety of materials. Whether it’s for apparel, promotional items, or decorative surfaces, UV DTF printing provides an unparalleled level of versatility that traditional printing methods often lack. With the ability to produce durable and visually stunning results, it’s no wonder that businesses are turning to this digital printing technology for their custom printing needs. As we explore the many facets of UV DTF printing, it becomes clear how essential it is for modern design and manufacturing.

Sometimes referred to as direct to film printing, UV DTF printing signifies an innovative leap in the realm of digital printing solutions. By employing advanced ultraviolet curing techniques, this method allows for the application of vibrant graphics on various substrates, making it an ideal choice for those interested in personalized products. The versatility extends beyond fabric, catering to hard surfaces such as plastics and metals, demonstrating its adaptability across industries. This technology not only elevates the quality of print but also enhances design opportunities for businesses looking to stand out in a competitive market. Overall, UV DTF printing represents a fusion of creativity and functionality, allowing for limitless possibilities in custom printing.

Understanding UV DTF Printing Technology

UV DTF printing stands out in the realm of digital printing technology, harnessing the power of ultraviolet light to create stunning designs. This innovative process begins with specialized inks that, upon exposure to UV light, cure quickly and adhere firmly to various films and surfaces. This efficiency allows for high-speed production and the ability to print intricate patterns and vibrant colors that traditional methods often struggle to achieve.

Along with its speed, UV DTF printing showcases remarkable flexibility, enabling businesses to choose from an extensive range of materials. It caters to both soft fabrics—ideal for custom apparel—and hard surfaces like wood and metal. This broad spectrum ensures that entrepreneurs and designers can meet diverse market demands while maintaining exceptional quality.

The Advantages of DTF Printing for Businesses

Businesses today are increasingly turning to UV DTF printing due to its myriad advantages. One of the primary benefits is the durability of printed designs, which resist scratching and fading over time. This reliability is crucial for items subjected to wear, such as promotional goods and customized apparel, providing customers with lasting value.

Moreover, UV DTF printing offers incredible design versatility. Whether producing one-off custom pieces or large-scale orders, the printing technology adapts to specific needs without compromising quality. This adaptability not only enhances operational efficiency but also allows companies to tailor their offerings according to customer preferences.

Applications in Custom Fabric Printing

Custom fabric printing has been transformed by UV DTF technology, which allows for vibrant and detailed images directly on textiles. This capability is essential for fashion designers looking to make a statement or businesses wanting to create unique promotional apparel. UV DTF ensures that colors remain vivid and true to their original intent, allowing brands to maintain their aesthetic integrity.

Additionally, the softness and flexibility of fabrics remain intact, a critical factor in the apparel industry. With UV DTF printing, designers can experiment with various materials, from cotton to polyester, without the usual limitations associated with other printing techniques—opening up new avenues for creativity in fashion.

Transforming Hard Surface Printing

UV DTF printing is not limited to textiles; it has extended its reach into hard surface printing, revolutionizing how promotional products are created. Items like customized awards, photo frames, and business signage can now feature high-definition prints that enhance visual appeal and marketability. The technology allows for detailed designs on surfaces that were previously challenging to print on, such as glass and ceramic.

Utilizing UV DTF for hard surfaces also provides another level of durability, as the inks are resistant to scratches and environmental wear. This reliability is key for items that will be displayed or handled frequently, ensuring that the investment in personalized goods remains intact over time.

Creating Vibrant Custom Products

UV DTF printing provides a unique opportunity for businesses to create vibrant custom products that attract customers’ attention. The ability to print in rich, bold colors means that companies can effectively communicate their brand message while maintaining an artistic flair. Products like custom T-shirts, unique home décor items, and personalized accessories stand out due to the brilliant graphics made possible by this technology.

Further, businesses can utilize the advantages of DTF technology to launch limited edition items or seasonal promotions, capturing consumer interest through innovative designs. As personalization becomes increasingly preferred in the market, UV DTF printing is setting brands apart with bespoke offerings that resonate with their target audiences.

Future Trends in UV DTF Printing

As technological advancements continue to influence the printing industry, UV DTF printing is poised for significant growth. Experts anticipate an increase in demand for this printing method as more businesses seek creative solutions that combine speed, quality, and customization. Innovations in ink formulations and printing equipment promise to enhance printing capabilities, resulting in even faster turnaround times and lower operational costs.

Moreover, as environmental awareness rises, manufacturers are likely to focus on sustainable practices, promoting UV DTF as a greener choice compared to traditional printing methods. The focus on reducing VOC emissions from inks aligns with current trends, allowing companies to position themselves as eco-conscious while benefiting from high-quality output.

Frequently Asked Questions

What are the advantages of using UV DTF printing for custom fabric printing?

UV DTF printing offers numerous advantages for custom fabric printing. The durability of UV-cured inks ensures that prints resist fading, scratching, and weathering, making them perfect for both indoor and outdoor apparel. Additionally, the technology allows for vibrant color quality and intricate designs, providing limitless creative possibilities for custom garments.

How does UV DTF printing differ from traditional UV printing methods?

UV DTF printing differs from traditional UV printing in that it utilizes a film transfer method, allowing prints to be applied to various surfaces beyond flat materials. This flexibility enables UV DTF printing to cater not only to fabrics but also to hard surfaces like wood, glass, and plastic, expanding its applications significantly.

Can UV DTF printing be used for hard surface printing?

Yes, UV DTF printing is highly effective for hard surface printing. It allows for high-resolution designs to be transferred onto various materials such as wood, metal, and glass, making it ideal for products like promotional items, signage, and customized gifts. The durability of the prints ensures long-lasting quality on these surfaces.

What types of products can be created using UV DTF printing technology?

Using UV DTF printing technology, a wide range of products can be created, including custom apparel like t-shirts and hoodies, promotional items such as mugs and coasters, and decorative pieces for home and office. This versatility makes UV DTF a popular choice for businesses seeking unique and personalized products.

Is UV DTF printing an environmentally friendly option compared to other printing methods?

Yes, UV DTF printing is considered more environmentally friendly than many other printing methods. It utilizes inks that often contain lower levels of volatile organic compounds (VOCs), reducing harmful emissions. This eco-friendly aspect is attractive to businesses aiming to adopt sustainable practices in their production processes.

What should businesses consider when choosing UV DTF printing for their products?

Businesses should consider factors such as the durability and vibrancy of prints, the variety of materials that can be printed on, and the cost-effectiveness of UV DTF printing. Additionally, evaluating the technology’s capability to meet specific customization needs and its environmental benefits can help in making an informed choice.

| Key Features | Description |

|---|---|

| Durability | Resistant to scratching, fading, and weathering, suitable for indoor and outdoor applications. |

| Vibrant Color Quality | Produces brilliant colors and intricate designs that enhance product aesthetics. |

| Versatility Across Materials | Works on both fabrics (cotton, polyester) and hard surfaces (wood, plastic, glass). |

| Environmentally Friendly | Lower VOC levels make it a more sustainable choice compared to traditional inks. |

| Cost-Effective Solutions | Reduces production costs and waste, providing economical options for businesses. |

Summary

UV DTF printing is a revolutionary technique that combines durability, vibrant colors, and versatility across various materials, making it a preferred choice for many businesses today. This method allows intricate designs to be seamlessly transferred onto fabrics and hard surfaces, which not only enhances the aesthetic appeal of products but also promotes sustainability through lower VOC emissions. As the demand for customized solutions continues to grow, UV DTF printing stands out as an innovative option that can significantly enhance customer engagement and satisfaction.