UV DTF Gangheet is revolutionizing the printing landscape, merging UV Direct to Film printing with innovative methods for optimizing designs. This technique not only enhances print quality but also allows for the efficient ganging of multiple images on a single sheet, saving resources and time. As businesses seek to implement best practices for DTF printing, understanding UV printing techniques becomes essential. In our exploration of UV DTF Gangheet, we delve into critical aspects such as material selection, image preparation, and curing processes that elevate print durability. This comprehensive guide equips you with the knowledge to excel in maximizing the potential of your printing endeavors.

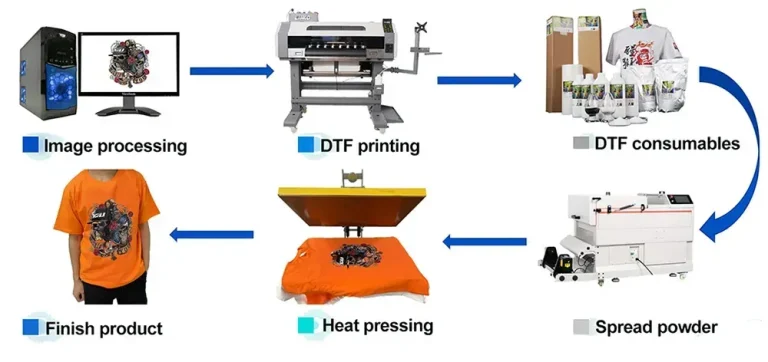

When we talk about UV DTF Gangheet, we are essentially referring to a transformative approach in digital film printing. This method, also known as Direct to Film printing, functions by applying high-quality images onto films destined for various surfaces, including fabrics and hard materials. Utilizing the latest UV printing methods, practitioners can develop gang sheets that facilitate multiple designs on a single substrate, streamlining production processes. The integration of advanced UV techniques enriches the final output and meets the growing demand for vibrant, personalized products. Understanding these facets is crucial for anyone interested in optimizing their printing business and achieving superior results.

Understanding the Basics of UV DTF Printing

UV DTF printing, which stands for Ultra Violet Direct to Film printing, merges UV printing technology with digital transfer applications. This mature method is designed to reproduce vibrant colors and intricate designs on various substrates, thanks to the advanced UV curing techniques. The process begins with printing a high-resolution image onto a specialized film, which is then transferred to the desired surface, such as textiles or rigid materials. The efficiency of UV DTF printing lies in its ability to deliver exceptionally detailed prints that withstand the test of time through prolonged exposure to sunlight or wear and tear.

The UV DTF printing method stands out due to its effective use of ink, which is cured instantly upon exposure to UV light, thus allowing for quicker turnaround times. This is particularly advantageous for businesses needing rapid responses for custom orders. Furthermore, UV DTF printing is adaptable, enabling the production of high-quality prints on both soft and hard surfaces, making it a versatile choice for various industries.

The Role of Gang Sheets in Printing Efficiency

Gang sheets are a vital aspect of UV DTF printing, enabling multiple designs to be printed on a single sheet of film. This technique maximizes material utility and minimizes waste, which is essential for cost-effective production. By organizing different graphics that have similar printing settings on a gang sheet, producers can significantly cut down on setup times and achieve economies of scale, making it a best practice in the industry.

Additionally, employing gang sheets streamlines the printing process, allowing for multiple designs to be cured simultaneously. This simultaneous curing not only speeds up the workflow but also ensures a uniform finish across all designs. Businesses leveraging gang sheets can fulfill customer demands more efficiently, leading to enhanced productivity and potentially higher profitability.

Best Practices for Effective UV DTF Gangheet Implementation

To fully leverage the benefits of gang sheets in UV DTF printing, implementing a few best practices is paramount. First, ensure that image preparation is done meticulously; using high-resolution vector images can significantly improve print quality. When designing gang sheets, it’s advisable to group similar images together to optimize space and reduce printing errors. Proper file management will also aid in organizing designs efficiently, streamlining the transition from design to print.

Moreover, regularly testing your gang sheets under different printing conditions can preemptively address potential issues. This practice helps in fine-tuning printer settings and ink choices, ensuring vibrant prints that adhere well to various substrates. Communicating with customers about their preferences will further refine gang sheet configurations, resulting in products that meet or exceed client expectations.

Advanced Techniques for Improving Print Quality

Investing in the latest UV printing technology and employing advanced faceting techniques can vastly improve the quality of UV DTF prints. Utilizing updated software for print management allows for substantial customization and fine-tuning of images before they are printed. Additionally, integrating color profiling tools can enhance color accuracy, ensuring that the printed output matches the intended design. Regular calibration of printing equipment ensures consistent color reproduction and quality across multiple print jobs.

Another key aspect to improving print quality involves selecting the right curing technologies. Ink that is adequately cured via UV light yields superior durability and adhesion, diminishing the risks of fading or peeling. Businesses should stay informed about emerging UV curing technologies, as improvements in this area can dramatically enhance the performance of UV DTF printing.

Emerging Trends in the UV DTF Printing Landscape

As the printing industry evolves, new trends in UV DTF printing are emerging that reflect broader technological and consumer shifts. One significant trend is the increasing emphasis on sustainability, with companies looking to adopt eco-friendly inks and materials. This move towards greener practices speaks to a larger audience of environmentally conscious consumers and can set businesses apart in a competitive market.

Another growing trend is the integration of digital tools that enhance the design and production phases. These smart software solutions facilitate layout optimization for gang sheets, allowing for more creative freedom while minimizing waste. Such technologies are invaluable for businesses that wish to capitalize on the rising demand for customized print solutions, particularly in niches like apparel and promotional merchandise.

Ensuring Maintenance and Longevity of Printing Equipment

Maintenance of UV DTF printing equipment is crucial for sustaining print quality and operational efficiency. Regular cleaning schedules should be established to remove ink residue and prevent the buildup of debris, which can adversely affect print output. This includes checking and maintaining the ink delivery systems, print heads, and UV curing units. A well-maintained printer not only delivers superior quality prints but also enjoys a longer lifespan, ultimately saving costs for the business.

Moreover, document the maintenance process and track equipment performance over time. Understanding trends in printer functionality can help in identifying issues before they become critical. Engaging in proactive maintenance strategies ensures that the printing equipment operates at its best, reducing the likelihood of unexpected downtime and production delays.

Frequently Asked Questions

What is UV DTF printing and how does it utilize gang sheets?

UV DTF printing, or UV Direct to Film printing, is a technique that transfers high-resolution images onto films for application on various substrates. It utilizes gang sheets to arrange multiple designs on a single sheet, optimizing material use and reducing costs while maintaining high print quality.

What are the best practices for preparing gang sheets in UV DTF printing?

Best practices for preparing gang sheets in UV DTF printing include ensuring high-resolution images are used, maintaining consistency in color modes, and testing multiple designs together to optimize layout and production efficiency. This way, you reduce waste and improve throughput.

How can printer calibration affect UV DTF gangheet quality?

Proper printer calibration is crucial in UV DTF gangheet printing as it ensures accurate color representation and consistent print quality. Regularly calibrating your printer and testing settings can prevent issues such as color discrepancies and output defects.

What materials are ideal for use in UV DTF gangheets?

Choosing the right films and substrates is essential for successful UV DTF gangheets. Films should be compatible with UV inks and the intended substrates, whether textiles or hard surfaces, to ensure quality and durability in prints.

How does the curing process impact UV DTF printing on gang sheets?

The curing process in UV DTF printing involves applying UV light to set the ink. Proper curing is critical to ensure that prints adhere well and maintain durability. Insufficient curing can lead to fading and peeling, compromising the quality of designs on gang sheets.

What are some current trends in UV DTF printing related to gang sheets?

Current trends in UV DTF printing include a shift towards sustainability with eco-friendly inks, digital integration for design and print management, and a growing demand for customized applications, all of which enhance the effectiveness of gang sheets in diverse printing scenarios.

| Topic | Details |

|---|---|

| Introduction to UV DTF Printing | A revolutionary technique combining UV printing with digital transfer, ideal for high-resolution images on various substrates. |

| Gang Sheets Concept | Using gang sheets to arrange multiple designs on one film sheet, optimizing material usage and costs. |

| Key Techniques | 1. Optimal material selection. 2. High-resolution image preparation. 3. Printer calibration. 4. Adequate curing technology. 5. Streamlined operational workflow. |

| Best Practices | – Conduct print testing. – Understand ink properties. – Maintain regular cleaning and maintenance. – Improve customer communication. |

| Current Trends in UV DTF | 1. Shift towards sustainability in inks and materials. 2. Integration of design software with print management. 3. Increasing demand for customized applications. |

Summary

UV DTF Gangheet is revolutionizing the printing industry, providing businesses with advanced capabilities for producing high-quality, customized products. The integration of gang sheets in UV Direct to Film printing allows for efficient use of materials and faster production times, emphasizing cost-effectiveness while maintaining artistic integrity. This innovative technique not only enhances design flexibility but also aligns with the growing demand for sustainability. As the market continues to evolve, mastering UV DTF Gangheet and adhering to best practices will empower businesses to thrive and meet the changing needs of their customers.