UV DTF Gangheet printing has revolutionized the printing industry by offering an innovative solution for producing vibrant, high-quality images on a wide range of substrates. This advanced printing technology leverages UV-cured inks, ensuring durability and striking color accuracy that meet the demands of modern consumers. As more businesses seek the best DTF printers for their projects, understanding the key elements of UV DTF equipment becomes essential. The gangheet printing process not only enhances the visual appeal of designs but also allows for greater versatility in materials, making it a preferred choice for professionals. In this guide, we will explore the intricacies of selecting the right equipment and maximizing the benefits of UV DTF Gangheet printing in your operations.

In recent times, the world of digital printing has seen a surge in techniques such as Direct to Film printing that is powered by ultraviolet (UV) technology. This cutting-edge approach, often referred to as UV DTF printing, enables artists and businesses to achieve exceptional results by applying inks directly onto various films for transfer onto diverse surfaces. By utilizing the gangheet printing approach, these methods cater to an array of materials, enhancing design capabilities and satisfaction for end users. As enterprises search for the most effective printing solutions, comprehending the nuances of UV printing materials and equipment becomes vital. This overview will help shed light on how to effectively utilize DTF printing technology for your specific needs.

Key Features of UV DTF Equipment

When choosing UV DTF equipment, it’s essential to understand the key features that distinguish high-quality machines from lower-tier options. Look for printers that offer advanced functionalities such as precise print resolution and rapid processing speeds. High-resolution printers, usually rated at 1440 dpi or higher, deliver stunning details, making them perfect for intricate designs and high-end applications. Additionally, the speed of the printer, indicated in square feet per hour, can greatly impact your productivity, allowing for quicker turnaround times on orders.

Another significant feature of quality UV DTF printers is their ability to handle a wide range of UV printing materials. Versatile machines can print on various substrates, from textiles to rigid surfaces like wood and metal. This capability expands your printing possibilities and attracts a broader customer base, which is crucial in today’s competitive market. When evaluating printers, consider how each model’s specifications align with your specific project needs, including target audience and material types.

Understanding DTF Printing Technology

Direct to Film (DTF) printing technology is revolutionizing the way customized designs adorn products. The process involves printing on a special film using high-quality UV ink, which is then transferred onto the desired substrate. One of the critical advantages of DTF printing is its ability to produce vibrant colors and sharp images on a wide variety of materials. This adaptability makes it an ideal choice for businesses looking to diversify their product offerings.

Another vital aspect of DTF printing technology is the compatibility of different materials with UV inks. Unlike traditional printing methods, DTF printers can easily print on challenging substrates that other processes struggle with. This means artists and manufacturers can experiment with innovative products and designs without being hindered by material limitations. As DTF technology continues to evolve, staying aware of emerging trends and techniques will ensure you remain competitive in the market.

Unpacking the Gangheet Printing Process: A Comprehensive Guide

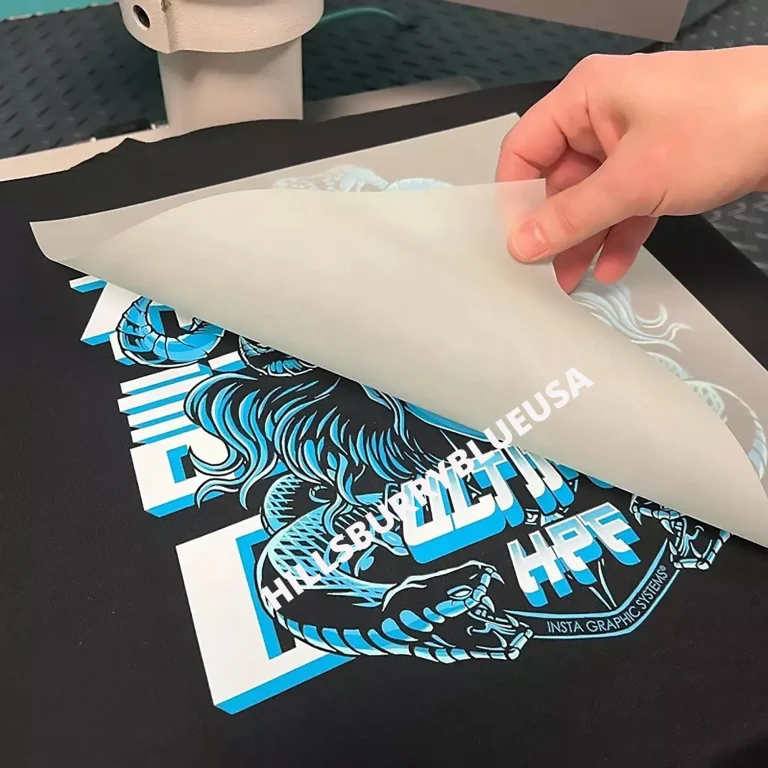

The Gangheet printing process is a revolutionary method that integrates UV DTF technology, allowing printers to achieve stunning results on diverse surfaces. This technique involves first printing your design onto a special transfer film with high durability and color vibrancy. Once the design is complete, it undergoes a curing process with UV light, which solidifies the ink and prepares it for the application on the chosen substrate.

The beauty of the Gangheet printing process lies in its flexibility. By using UV-cured inks, businesses can use this technique on harder surfaces such as glass or metal without losing quality. This opens up numerous avenues for product customization, ranging from promotional items to fine art applications. Understanding the nuances of Gangheet printing will enable you to leverage its capabilities effectively, enhancing your operational workflow.

Choosing the Best DTF Printers

Selecting the best DTF printers requires careful consideration of multiple factors, including print speed, resolution, and build quality. Providers like [Brand A] and [Brand B] have established a reputation for producing reliable printers that cater to varying sizes of businesses and printing needs. Businesses striving for high-quality outputs should prioritize options that boast both exceptional speed and resolution, ensuring they meet client demand efficiently.

Moreover, it’s important to review actual user experiences with various printers. Online reviews and community feedback can provide insight into which models excel in specific areas, such as ease of use or durability. Look for printers that consistently receive positive accolades for their output quality and customer support, as these factors can heavily influence your printing business’s success.

Maximizing Material Compatibility in UV DTF Printing

Material compatibility is a fundamental aspect of UV DTF printing that can greatly impact the quality and durability of your prints. Different substrates require unique treatments and ink formulations, and not all printers are capable of handling the diverse array of materials available. It’s vital to select printers that are designed to work seamlessly with various DTF printing materials, including textiles, plastics, and hard surfaces.

By investing in UV DTF printers with superior material compatibility, businesses can expand their product lines, providing customers with a variety of vibrant and durable products. Ensure that the printer you choose is compatible with UV inks specifically formulated for your substrates, as this will enhance adhesion and overall quality, resulting in longer-lasting prints that elevate your brand’s reputation.

The Importance of Software in DTF Printing

Software compatibility is another critical factor when choosing UV DTF printing equipment. Your printing software can significantly affect the speed, quality, and efficiency of the printing process. High-quality DTF printers should be supported by advanced Raster Image Processor (RIP) software, which enhances color management and optimizes print settings specific to your materials and designs.

Additionally, ensuring that your printer is compatible with the design software you intend to use is vital for operational efficiency. Seamless integration between hardware and software minimizes workflow interruptions, allowing you to focus more on design innovation and product creation. Overall, a well-matched setup can streamline operations, improving your business’s productivity and output quality.

Frequently Asked Questions

What is UV DTF Gangheet printing and how does it work?

UV DTF Gangheet printing is a state-of-the-art printing technology that utilizes UV-cured inks to print vibrant and high-quality images directly onto various substrates. This printing process involves transferring designs onto a film before applying them onto the desired materials, enabling remarkable detail and durability.

How do I choose the best DTF printers for UV DTF Gangheet printing?

To select the best DTF printers for UV DTF Gangheet printing, consider key factors such as print resolution, speed, material compatibility, software integration, and user-friendliness. These specifications will ensure that your business can produce high-quality prints efficiently on a variety of surfaces.

What UV printing materials are ideal for UV DTF Gangheet printing?

The ideal UV printing materials for UV DTF Gangheet printing include a wide range of substrates such as textiles, rigid surfaces (like wood and metal), and flexible films. Ensure that your chosen printer supports the specific materials you plan to work with to maximize the technology’s versatility.

What are the maintenance costs associated with UV DTF equipment?

Maintenance costs for UV DTF equipment involve expenses related to consumables like UV inks and specialized films, as well as routine maintenance services. It’s important to factor these costs into your budget to ensure sustained operation and print quality in your UV DTF Gangheet printing business.

How does software compatibility affect UV DTF Gangheet printing operations?

Software compatibility is crucial in UV DTF Gangheet printing as it ensures smooth workflow and optimized print quality. Using compatible design and RIP software allows for better color management and speeds up the printing process, enhancing overall productivity.

What are the benefits of using UV-cured inks in the gangheet printing process?

Using UV-cured inks in the gangheet printing process provides several benefits, including enhanced durability, vibrant color reproduction, and better adhesion to various substrates. These inks also reduce drying times, allowing for quicker project turnaround and improved operational efficiency.

| Key Considerations | Description |

|---|---|

| Identify Your Printing Needs | Assess types of projects, target market, and materials to print. |

| Printer Specifications | Look for high resolution and printing speed for better quality and efficiency. |

| Material Compatibility | Ensure printer handles a variety of substrates and uses UV-cured inks. |

| Software Compatibility | Check compatibility with design and RIP software for optimized operations. |

| Ease of Use | Opt for user-friendly interfaces to minimize training and streamline workflows. |

| Cost of Consumables | Consider long-term costs of inks and maintenance compared to the initial price. |

| After-Sales Support and Maintenance | Look for warranty programs and reliable customer service for peace of mind. |

| Reviews and Case Studies | Research user experiences and performance feedback on different printer models. |

Summary

UV DTF Gangheet Printing is revolutionizing the printing industry with its innovative technology and versatility to print on various substrates. Choosing the right equipment is crucial for achieving high-quality outputs and maintaining operational efficiency. By understanding your specific printing requirements, evaluating printer specifications such as resolution and speed, and confirming compatibility with materials and software, you can make an informed decision that enhances your business’s capabilities. Additionally, considering factors like ease of use, long-term operational costs, and after-sales support will ensure your investment yields profitable returns. A well-informed choice in UV DTF Gangheet printing equipment not only meets your current needs but also positions you for future success in a competitive market.