The UV DTF Gangheet method emerges as a pioneering force in the realm of digital printing, harmonizing the unique benefits of UV printing and DTF (Direct-to-Film) techniques. This innovative hybrid printing technology not only promises vibrant and durable outputs but also facilitates versatile applications on a myriad of substrates, ranging from textiles to rigid surfaces. With a keen focus on sustainable printing practices, the UV DTF Gangheet approach employs eco-friendly UV inks, minimizing environmental impact while preserving color fidelity and sharpness. Whether for fashion, merchandising, or industrial uses, this method encourages creative design possibilities and rapid production cycles, making it a go-to solution for businesses aiming for excellence in their prints. As we dive deeper into the intricacies of the UV DTF Gangheet process, it’s evident that it solidifies its place in the future of printing.

Delving into the transformative landscape of contemporary print techniques, the UV DTF Gangheet stands out as a remarkable synthesis of UV and direct-to-film strategies. This alternative digital printing approach offers a seamless integration of two powerful methodologies, enhancing print durability and quality while also promoting sustainability. By utilizing ultraviolet radiation for immediate curing, this inventive process ensures not only quick production times but also superior color vibrancy that adheres well to diverse materials. The hybrid properties of UV DTF printing lend themselves to creating striking designs ideal for both clothing and promotional items, strengthening its appeal among various industries. As printing technologies evolve, the UV DTF Gangheet method exemplifies a forward-thinking solution that amplifies creativity while reducing traditional printing drawbacks.

The Evolution of Printing Technology

Since the advent of digital printing technologies, businesses have been on a quest for methods that deliver not only speed but also quality and flexibility. Traditional printing techniques often fell short in meeting modern demands, leading to the development of innovative solutions. The evolution of printing technology has introduced various methods, including UV printing, which uses ultraviolet light to dry ink instantly, providing advantages like rapid production cycles and vibrant colors.

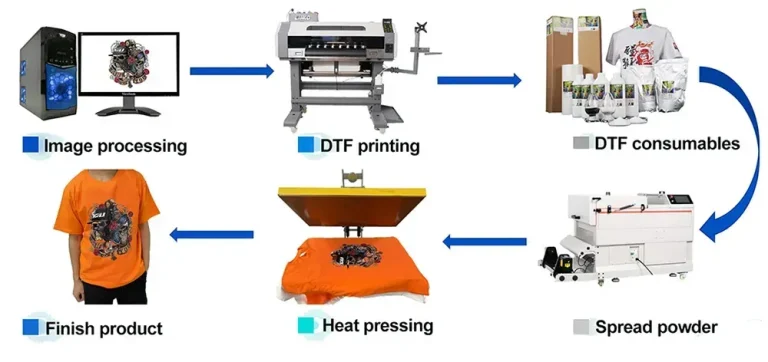

In parallel, DTF printing emerged as a contender in the garment industry, allowing prints to be transferred onto a variety of materials including textiles. The combination of these two groundbreaking techniques in the UV DTF Gangheet method signifies a pivotal moment in printing. It highlights an ongoing trend towards hybrid solutions that leverage the best aspects of established methods to create superior results.

Key Features of UV DTF Gangheet

The standout feature of the UV DTF Gangheet method is its hybrid approach, blending the strengths of both UV and DTF printing principles. This leads to enhanced durability of prints, which become resistant to various environmental factors while maintaining high quality over time. The method caters to a diverse range of substrates, including textiles and rigid surfaces, making it a versatile option for businesses aiming to explore new creative realms.

Another notable characteristic of this method is the glossy finish achieved through UV curing. This aesthetic quality is especially appealing for fashion products and promotional merchandise, where visual impact plays a crucial role. These features collectively make UV DTF Gangheet a powerful tool in the hands of designers and printers aiming to elevate their offerings.

The Benefits of UV DTF Gangheet for Businesses

Businesses that adopt the UV DTF Gangheet method can reap multiple benefits, including improved production speed and cost-effectiveness. The quick drying times characteristic of UV printing allow companies to streamline their processes, reducing the time from production to delivery. This efficiency can be a critical advantage in industries that operate under tight deadlines.

Moreover, this hybrid method proves favorable for small businesses and startups that may have limited resources. The reduced initial setup and operational costs compared to traditional methods such as screen printing make it financially viable for smaller production runs. As a result, UV DTF Gangheet is not just beneficial for large manufacturers; it opens doors for new entrants in the printing market.

Sustainability in Printing: A Modern Necessity

As environmental concerns become increasingly urgent, the printing industry is also making strides towards sustainability. The UV DTF Gangheet method contributes to this trend by utilizing UV inks that can be low in volatile organic compounds (VOCs). This eco-friendly approach not only minimizes harmful emissions but also aligns with consumer preferences for sustainable products.

Adopting hybrid printing technologies like UV DTF Gangheet allows businesses to meet the growing demand for environmentally conscious practices without compromising on quality. This shift towards sustainable printing is essential for companies aiming to enhance their brand reputation and appeal to eco-conscious consumers.

Comparative Analysis: UV DTF Gangheet vs Traditional Techniques

When comparing UV DTF Gangheet to traditional printing methods, the differences are stark. Traditional screen printing, for example, often requires extensive setup and is time-consuming, especially for complex designs. In contrast, the UV DTF method streamlines the design process, facilitating quicker adjustments and enabling small production runs without significant financial burden.

Additionally, the durability and quality of prints produced via UV DTF Gangheet are generally superior to traditional methods. With vibrant color reproduction and resistance to fading, businesses can assure their clients of lasting quality, which is essential for building long-term customer relationships and brand loyalty.

Future Developments in Hybrid Printing Technologies

The future of hybrid printing technologies, including UV DTF Gangheet, looks promising as advancements continue to unfold. Innovations are expected to further enhance the capabilities of these methods, potentially integrating new materials and techniques that push the boundaries of traditional printing. As technology progresses, it will be fascinating to see how UV DTF continues to evolve and adapt to consumer needs and market trends.

Furthermore, as more companies explore the benefits of combining digital and traditional printing techniques, we may witness a surge in hybrid solutions tailored to specific industry requirements. This trend points toward a future where printing is not only quicker and more efficient but also increasingly customized to meet diverse demands.

Frequently Asked Questions

What are the main advantages of UV DTF Gangheet compared to other printing methods?

The UV DTF Gangheet method combines the strengths of UV printing and DTF printing, providing advantages such as enhanced durability, versatility in printing on various substrates, and the ability to achieve glossy finishes. This hybrid approach offers businesses superior quality, consistency in color reproduction, and faster production times, making it a game-changer in the printing industry.

How does UV DTF gangheet printing enhance color quality and durability?

UV DTF Gangheet enhances color quality and durability through its advanced UV curing technology, which instantly dries inks to produce vibrant colors that resist fading. Moreover, the DTF component allows for high-quality transfers onto different materials, leading to prints that are not only visually appealing but also durable against wear and environmental factors.

Is UV DTF Gangheet a sustainable printing option?

Yes, UV DTF Gangheet incorporates eco-friendly practices common in UV printing. Many UV inks used in this method are free from volatile organic compounds (VOCs), making them a safer choice for the environment. Additionally, the reduced waste associated with the efficient DTF process makes it a more sustainable option compared to traditional printing methods.

What types of materials can be printed using UV DTF Gangheet?

UV DTF Gangheet is versatile, allowing for printing on a wide range of materials including textiles, such as cotton and polyester, as well as rigid surfaces like plastics, metal, and glass. This flexibility opens up a multitude of creative possibilities for businesses looking to produce unique printed products.

Can small businesses benefit from using the UV DTF Gangheet printing method?

Absolutely! The UV DTF Gangheet method is particularly advantageous for small businesses and startups due to its cost-effectiveness and lower production barriers. The hybrid printing technology allows for short runs with minimal setup costs, enabling smaller operations to compete effectively in the market.

What industries can benefit most from UV DTF Gangheet printing?

Various industries can benefit from UV DTF Gangheet printing, particularly those in fashion, merchandise, promotional products, and custom signage. The ability to produce high-quality prints quickly and on diverse substrates makes it ideal for businesses aiming to create unique, durable products that stand out in competitive markets.

| Key Features | Advantages | Applications |

|---|---|---|

| Combines UV and DTF printing technologies | Enhanced durability of prints | Textiles and rigid surfaces including plastics and metal |

| Quick drying times due to UV curing | Consistent quality across different print batches | Fashion, merchandise, and promotional products |

| Can print on diverse substrates | Cost-effective for small production runs | Garment printing and various custom items |

| Produces vibrant, high-resolution images | Speed of production comparable to UV printing | Ideal for businesses with tight deadlines |

Summary

UV DTF Gangheet is revolutionizing the printing landscape by seamlessly integrating the benefits of UV and DTF printing methods. This innovative approach offers unmatched durability, quick production times, and versatility across various substrates, making it an ideal choice for businesses aiming to deliver high-quality prints. As the industry shifts towards hybrid technologies, the UV DTF Gangheet method is establishing itself as a frontrunner, allowing businesses to maximize efficiency and creative possibilities in their printing endeavors.