Texas DTF isn’t just a buzzword—it’s a practical path to high-quality, high-margin apparel customization for shops and brands across the Lone Star State. Direct-to-film printing has matured through the 2020s and into 2025, delivering vibrant color, fabric compatibility, and cost efficiency. To succeed, Texas-based shops must understand DTF vs DTG—where each method shines and where it may fall short. Careful choices in equipment and consumables, from printers to curing steps, set the stage for reliable, scalable runs. A reliable finishing system and thoughtful workflow ensure consistent results across T-shirts, hoodies, bags, and other items.

Beyond the hype, digital-to-fabric transfer workflows are reshaping Texas print shops by combining film-based artwork with adhesive bonding and heat application. This transfer-on-film approach ties together related concepts like transfer films, adhesive powders, curing methods, and the role of the heat press in finishing. Using these alternative terms, brands can understand the same process as a film-based transfer system that yields durable, vibrant results on a wide range of textiles. Adopting an LSI-informed vocabulary helps content align with what buyers search for, from fabric compatibility to color management and production speed.

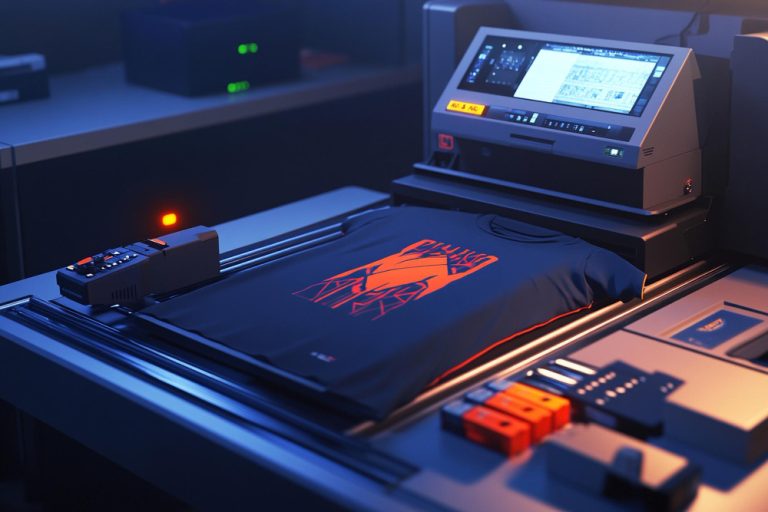

Texas DTF: Mastering Direct-to-Film Printing for Profitable Apparel Shops

Texas DTF isn’t just a buzzword—it’s a practical path to high-quality, high-margin apparel customization for shops across the Lone Star State. Direct-to-film printing has matured through the 2020s and into 2025, delivering vibrant color, broad fabric compatibility, and cost-efficient production for small businesses, sports teams, and event merch. In a market where speed, flexibility, and variety matter, DTF provides a strong value proposition for Texas brands looking to offer T‑shirts, hoodies, bags, and other items without the complexity of multiple production steps. By understanding how direct-to-film printing fits into local workflow and demand, shops can scale up while maintaining quality and margin.

To succeed locally, it’s essential to align equipment and processes with Texas’ fast-turnaround culture. Focus on a robust printer with reliable print heads, a wide color gamut, and a capable RIP workflow that can manage DTF films and powders. The right setup balances speed with consistent output, minimizes downtime, and supports on-demand merchandising for events and sports seasons. When evaluating options, consider production capacity, service availability in the region, and the integration of transfer films, adhesive powders, curing equipment, and a dependable heat press for DTF finishing. The result is a scalable operation that delivers durable, vibrant prints across cotton, blends, and even polyester.

DTF printers 2025 and the Full Workflow: Films, Powders, and the Heat Press for DTF in Texas

DTF printers 2025 bring higher reliability, broader color accuracy, and more efficient maintenance cycles, making direct-to-film printing an even more practical choice for Texas shops. As printers advance, the white underbase and color density improve on a range of fabrics—from light cottons to dark blends—while print speeds stay competitive for small runs and rapid turnarounds. In this era, success hinges on selecting DTF films and powders that deliver clean releases, strong adhesion, and wash durability across common substrates. The combination of strong print chemistry and dependable film/powder systems helps Texas businesses stay competitive for team uniforms, event merch, and boutique drops.

Putting the pieces together requires a well-defined workflow—from design to final product. Start with high-resolution artwork, color separations, and a suitable white underbase for dark fabrics. Print on the transfer film, then dust with adhesive powder and cure it effectively before heat pressing onto the garment. The heat press for DTF must be calibrated to the film’s guidelines, with proper dwell time and temperature to ensure a durable bond. In Texas, where customers demand fast delivery, a streamlined pipeline—backed by reliable films, powders, and curing equipment—reduces waste and improves consistency. Regular color management checks, test swatches, and ongoing training for staff help maintain repeatable results and a strong ROI on the DTF investment.

Frequently Asked Questions

What is Texas DTF and how does direct-to-film printing compare to DTG for Texas shops in 2025?

Texas DTF refers to using direct-to-film printing for apparel produced by shops in Texas. Direct-to-film printing prints designs onto a transfer film with pigment inks, then applies an adhesive powder and uses heat to bond the image to fabric. For Texas brands, DTF offers vibrant colors on a wide range of fabrics, strong results on dark garments, and scalable, cost-efficient production. Compared with DTG (direct-to-garment), DTF typically delivers brighter whites and better coverage on dark fabrics, with simpler multi-garment workflows and lower setup costs for mixed fabrics. By 2025, the technology is mature, with reliable printers, films, and powders suitable for fast local turnaround on team, event, and boutique merch.

What should a Texas-based business consider when selecting DTF printers 2025 and evaluating DTF films and powders for a reliable heat press for DTF?

Key considerations for Texas shops include selecting DTF printers 2025 that offer a reliable print head, wide color gamut, and robust RIP software with DTF color profiles; aim for 24–40 inch width and strong regional support. For DTF films and powders, choose films with clean release and appropriate thickness, and powders that melt evenly and bond reliably across common fabrics; test on your typical substrates. For the heat press, ensure correct temperature, pressure, and dwell times and plan a curing step for the powders. Finally, assess ROI and workflow: plan color management, minimize waste, and factor in maintenance and training to keep production efficient. This combination supports fast, durable, high-clarity DTF prints for Texas shops serving local businesses and events.

| Key Point | Summary | Texas DTF Relevance |

|---|---|---|

| What is DTF and why it matters in Texas | DTF prints designs onto transfer film with pigment inks, applies adhesive powder, and uses heat to bond to fabric. It works on cotton, blends, polyester, and some dark fabrics with vibrant whites and bold colors, making it versatile for diverse Texas product lines. | Showcases versatility, speed, and cost efficiency for Texas brands, teams, and events seeking broad fabric compatibility. |

| DTF vs DTG: core differences | DTG prints directly on garments (great soft hand feel on light fabrics, limited on darks). DTF uses a transfer film with adhesive powder for bonding, offering better color on dark fabrics, durability, scalable small runs, and easier multi-garment production. | Guides Texas shops on when to choose DTF for wide color ranges and varied fabrics. |

| Choosing the Right DTF Printer and Equipment in 2025 | Look for reliable print heads, wide color gamut, robust RIP software, suitable print width/speed (roughly 24–40 inches), strong ink density, solid color management, and accessible local support. | Critical for Texas operations facing event-driven deadlines; local service reduces downtime. |

| DTF Films and Powders: Why They Matter | Film quality and powder consistency affect transfer cleanliness, whites, and fine details. Consider release properties, thickness, compatibility with fabrics, and test on typical substrates. | Quality control is essential for Texas shops expanding product lines (caps, bags, athletic wear). |

| The DTF Workflow: Design to Final Product | A repeatable path: design prep (high-res, color separations, white underbase if needed) → print on transfer film → apply adhesive powder → cure powder → heat press → peel/finish → quality check. | Helps Texas shops produce efficiently with minimal waste and consistent results. |

| Common Challenges and Troubleshooting | White ink density, powder adhesion, film curl/misfeed, peeling after wash, color mismatch. Fixes include proper RIP calibration, even dusting, correct cure/press parameters, and color management. | Proactive problem-solving supports quick-turnaround Texas orders. |

| Costs and ROI for a Texas DTF Operation | Upfront printer, films, powders, and heat press plus ongoing consumables. ROI drivers include tiered pricing, bundles, stock management, local supplier networks, and team training. | Financial planning is essential for Texas entrepreneurs expanding merch capabilities. |

| DTF in 2025: Texas Playbook | Market maturity brings higher demand for on-demand, small-batch, fast-turnaround prints. More affordable printers and films improve accessibility. | Encourages Texas shops to embrace DTF to expand capabilities and reduce lead times. |

Summary

Conclusion: Texas DTF is a practical, scalable method for producing vibrant, durable apparel across a range of fabrics. By choosing reliable printers, high-quality transfer films and powders, and a disciplined workflow, Texas-based shops can meet the needs of local sports teams, boutique brands, and event merchandise with faster turnaround and consistent quality. Embracing DTF in Texas means expanding capabilities, reducing lead times, and offering a versatile solution that aligns with the state’s entrepreneurial spirit and demand for reliability and color-rich prints.