To increase throughput with a DTF gangsheet builder, brands and print shops can align layouts, materials, and timing for faster, more reliable results. This approach accelerates production without sacrificing quality. Smart planning reduces waste and keeps designs aligned on the sheet. Template libraries help teams move quickly with consistent results. As a result, throughput gains are realized without escalating costs.

In broader terms, boosting production pace hinges on smart sheet planning and end-to-end workflow orchestration, not simply faster hardware. Leading teams describe the same goal using terms like gangsheet optimization and batch printing workflow, where layouts pack more designs per sheet and process steps stay synchronized. Coupled with disciplined color management and automated preflight, this approach increases DTF printing efficiency and printing throughput across shifts while preserving consistency. By integrating with order management, RIP automation, and consumable planning, shops gain visibility, reduce downtime, and expand capacity without compromising quality. Over time, the combination of these concepts can translate into faster turnarounds, higher item counts per run, and healthier margins.

DTF gangsheet optimization for higher throughput: (increase throughput with a DTF gangsheet builder) and practical workflow gains

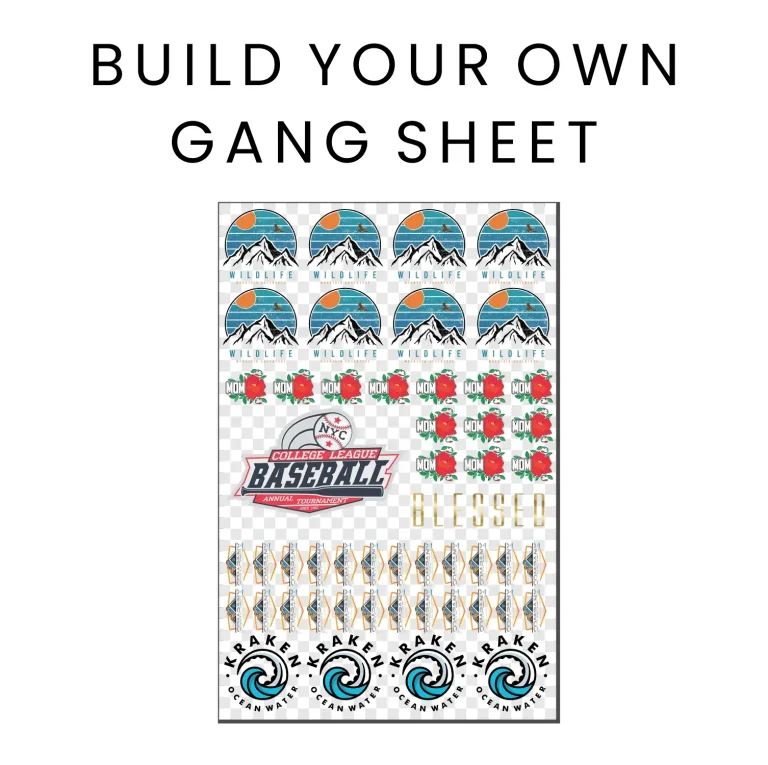

Using a DTF gangsheet builder reshapes design placement on a single sheet by considering margins, bleeds, color counts, and spacing up front. This gangsheet optimization reduces wasted substrate and streamlines post-processing steps, increasing the number of items printed per run. As a result, printing throughput rises because each pass through the RIP and printer yields more finished units without sacrificing edge-to-edge quality. The approach also supports a practical batch printing workflow by grouping similar designs and color profiles, minimizing setup time and ink changes between jobs.

To maximize impact, create templates for recurring motifs and product lines that capture common grid layouts and color counts. Automated preflight integrated with the gangsheet builder catches resolution, color space, bleed, and safe-zone issues before a run, preventing reprints and delays. Grid optimization, smart margins, and optional dynamic spacing let you pack more designs per sheet while preserving legibility, delivering higher DTF printing efficiency. Tracking metrics such as sheets per hour and designs per sheet provides a clear, data-driven view of throughput gains over time.

Automation-driven throughput: boosting DTF printing efficiency through preflight, batch management, and KPI-driven improvements

Automation removes repetitive tasks in file prep, color separation, and preflight, letting the DTF gangsheet builder handle layout packing while the batch printing workflow runs in the background. This reduces idle time, minimizes ink changes, and accelerates printing throughput, delivering measurable gains in DTF printing efficiency as designs are placed more strategically on each gangsheet.

Establish KPIs such as sheets per hour, designs per sheet, and material usage per job, and set baselines before implementing gangsheet optimization. Re-measure after deployment to attribute gains to the workflow changes. Document procedures and train operators on predefined templates, automated preflight, and batch planning to sustain improvements and maintain consistent quality across runs.

Frequently Asked Questions

How can I increase throughput with a DTF gangsheet builder through layout optimization and a batch printing workflow?

To increase throughput with a DTF gangsheet builder, focus on layout efficiency, batch printing workflow, and automation. Practical steps: 1) Predefine layouts for common designs to reduce setup time and ensure consistent margins and bleed; 2) Use grid optimization and smart margins to fit more designs per sheet; 3) Consolidate color counts to minimize ink changes and color switches; 4) Automate preflight and file prep to catch issues before RIP, cutting reprints; 5) Plan batch runs and queue management to maximize printer utilization; 6) Leverage dynamic spacing and rotation where permitted to increase capacity without sacrificing legibility; 7) Integrate with an end-to-end batch workflow for visibility and faster cycle times. Track progress with sheets per hour and designs per sheet to validate gains.

What metrics and best practices help sustain increase throughput with a DTF gangsheet builder, emphasizing gangsheet optimization and printing throughput?

Sustain throughput by measuring and optimizing key metrics: sheets per hour (SPH), designs per sheet, material usage per job, defect rate per batch, and labor time per job. Pair these with best practices: consistent color management using ICC profiles and regular printer calibration; regular maintenance of print heads and inks; clear SOPs for gangsheet creation, preflight checks, and batch planning; ongoing operator training; and feedback loops for continuous improvement. Start from baseline measurements on representative jobs, implement targeted gangsheet optimization, then re-measure to attribute gains to specific changes in workflow.

| Key Point | Description |

|---|---|

| DTF gangsheet builder: definition & purpose | A tool to arrange multiple designs on a single DTF gangsheet with precise spacing, bleeds, and color management to maximize items per sheet and minimize waste. |

| Why it matters | In a fast-paced textile customization environment, throughput, cost efficiency, and quality are critical; gangsheet strategies help meet deadlines and scale production. |

| Three pillars for gains |

|

| 7 practical tricks to increase throughput |

|

| Data-driven improvements: metrics |

|

| Best practices for long-term success |

|

| Real-world example | A mid-sized shop printing 2,400 shirts per week saw a 15–20% increase in sheets per hour after adopting preset layouts, automated preflight, and improved batch planning, with reduced waste and faster cycles. |

Summary

Increase throughput with a DTF gangsheet builder by aligning layouts, automation, and batch planning with performance tracking. A well-executed gangsheet strategy unlocks hidden capacity by optimizing layouts, streamlining prepress, and coordinating batch planning with printer performance. Start with predefined layouts, grid optimization, color consolidation, automated preflight, and disciplined batch management to establish a scalable, repeatable workflow that sustains gains across shifts and orders. By tracking the right metrics—SPH, designs per sheet, material usage, defect rate, and labor time—you can attribute improvements to specific changes and continuously raise throughput while maintaining quality and profitability.