Florida DTF trends are transforming how brands approach printed apparel in a sun-soaked market that prizes color, novelty, and speed, creating new opportunities for small studios and large manufacturers alike. The Florida market is characterized by a lively fashion scene, a steady stream of tourists, and a dense network of decoration shops that demand quick, reliable print methods, making DTF printing Florida a natural fit for on-demand production, capsule drops, and resort-to-street collections. Brands here increasingly expect vibrant, durable Florida DTF prints that survive frequent washing and the humid climate, while still feeling soft to the touch and light on the fabric. Designers can experiment with bold gradients, saturated tropical palettes, and crisp vector art without sacrificing the comfort and performance customers associate with Florida wear, leveraging direct-to-film printing for consistent results. The result is a dynamic ecosystem where creative concepts translate rapidly into scalable product lines across markets and channels.

From a terminology perspective, the same concept can be described with different terms that search engines recognize as related concepts, enhancing discoverability without duplicating language. Think of film-to-fabric transfers, heat-applied graphics, or digital textile printing as parallel approaches that share core capabilities with DTF. In plain terms, brands can explore on-demand garment decoration using transfer films, printer rigs, and curing methods that optimize color fidelity and wash durability across fabrics. By keeping content varied yet relevant, retailers and designers can reach audiences searching for related technologies like direct transfer methods and hybrid printing approaches.

1. Understanding Florida DTF Trends and Market-Driven Design

Florida DTF trends are reshaping how brands approach printed apparel in a market that thrives on color, novelty, and speed. By embracing direct-to-film printing, Florida brands can deliver vibrant designs with fast turnarounds that align with resort wear and event-ready apparel. This trend emphasizes bold color, tropical motifs, and scalable graphics that perform well across cotton tees, performance fabrics, and blended textiles, leveraging the soft hand feel and lightweight characteristics of DTF prints.

For designers, manufacturers, and retailers, understanding Florida DTF trends means recognizing how local tastes influence color palettes, subject matter, and finish choices. The ability to translate vibrant Florida aesthetics into Florida DTF prints helps brands stay competitive in tourism-driven retail channels and decoration shops that increasingly adopt DTF workflows. This contextual awareness also guides decisions about color management, curing, and substrate compatibility to sustain durability under Florida climates.

2. Substrates, Finishes, and Climate-Sensitive Choices for Direct-to-Film Printing

Choosing the right substrate is foundational to successful direct-to-film printing. Florida’s warm, humid environment and diverse fabric options—from cotton jerseys to performance blends—demand substrates that maintain color fidelity and wash durability. When planning Florida DTF prints, brands should evaluate fabric stretch, opacity, and cling to avoid cracking or substrate rejection during wear and washing.

Finishes and color durability are equally important. Distinguishing between light and dark garments requires a robust white underbase and precise transfer margins. In Florida, the print’s performance also depends on how the film adheres to fabrics and how curing steps withstand heat and humidity. Selecting high-quality DTF film and appropriate heat-press settings helps ensure long-lasting Florida DTF prints with vivid color and minimal fading.

3. Hardware, Inks, and Films: Building High-Quality Florida DTF Prints

Advances in printer technology, films, and inks are expanding what is possible with direct-to-film printing in Florida. A higher color gamut and improved detail enable intricate photographs and bold graphics to transfer with fidelity. Emphasizing white ink reliability is critical, especially on dark fabrics, to achieve crisp image reproduction across the Florida climate.

Quality-driven workflows rely on consistent film quality, reliable adhesion, and precise color management. DT film quality improvements reduce cracking and enhance transfer durability on a wide range of textiles. Calibration, RIP settings, and routine color tests on representative fabrics ensure that what designers see on screen aligns with the actual Florida DTF prints produced in hot, humid conditions.

4. Design Strategies for DTF Transfers in Florida Markets

Design strategies for DTF transfers should accommodate the transfer process from concept to garment. Vector art and clean line work translate well in direct-to-film printing, while photographic imagery may require careful color separation and high-resolution files. When developing Florida DTF prints, plan for white ink underbase on dark garments and reserve space for transfer margins to preserve detail during cutting and application.

Color palettes that reflect coastal vibes—tropical blues, coral tones, and lush greens—tend to resonate with Florida audiences. Testing how colors render on actual fabrics is essential, as the warm climate can influence tone and saturation. A practical workflow includes a design review, print proof, and a small batch test before committing to larger runs, ensuring Florida DTF prints stay vibrant and cost-efficient.

5. Production and Quality Assurance for Consistent Direct-to-Film Results

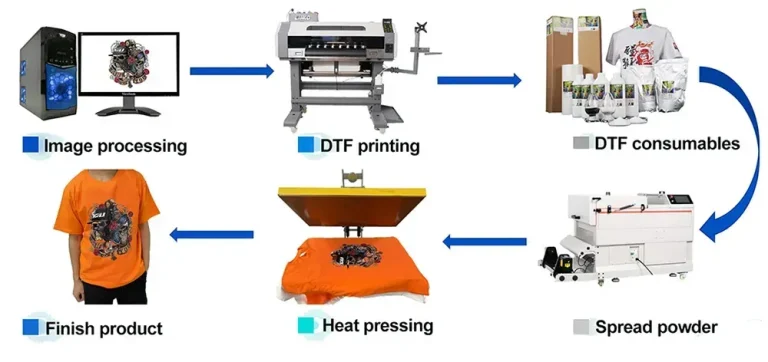

A smooth production flow is essential to capitalize on Florida DTF trends. From file prep to film curing, each step affects the final result. Key steps include substrate selection, artwork preparation for color separation, selecting a high-quality white underbase, and establishing a reliable heat-press regimen tailored to Florida temperatures and humidity.

Ongoing maintenance and QA are critical in Florida conditions. Regular printer and heat-press upkeep helps prevent downtime. Inventory planning, dye migration testing on different fabrics, and adherence to washing instructions all contribute to long-lasting Florida DTF prints. Building strong relationships with suppliers of films, inks, and transfer papers also helps preserve quality as trends shift.

6. Marketing, Collaboration, and Case Studies in Florida DTF Printing

Marketing Florida DTF trends hinges on storytelling that highlights the transfer process, color fidelity, and durability. Brands should align product stories with regional tastes—resort wear, event kits, and casual lifestyle apparel—while leveraging online content and visual merchandising that showcases the soft hand feel and vibrancy of Florida DTF prints.

Real-world examples showcase how direct-to-film strategies translate into market differentiation. Miami boutiques and Tampa coastal shops illustrate successful Florida DTF trends by pairing bold tropical prints with rapid, scalable production. These case studies demonstrate the benefits of collaborating with local designers and celebrities to accelerate adoption of direct-to-film printing while maintaining speed, quality, and margins in Florida markets.

Frequently Asked Questions

What are the current Florida DTF trends and how should brands respond?

Florida DTF trends show bold color palettes, tropical motifs, and fast turnarounds in resort wear and event apparel. To respond, brands should invest in color‑accurate workflows, test substrate compatibility (cotton, blends, performance fabrics), and build small, repeatable Florida DTF prints collections.

How does DTF printing Florida influence color vibrancy and durability of Florida DTF prints on common fabrics?

DTF printing Florida delivers high color gamut and soft hand feel for both light and dark fabrics. For durability, use a strong white underbase on dark garments, calibrate color profiles, and validate curing on target fabrics in Florida’s climate.

What design strategies align with Florida DTF trends for resort wear and event apparel?

Design for the DTF transfer by prioritizing vector art, planning white ink underbase for dark fabrics, and incorporating tropical motifs, bold typography, and coastally inspired palettes. Test colors on actual fabrics and run proofs before large batches.

What production and workflow steps are essential to capitalize on Florida DTF trends?

Key steps include selecting suitable substrates, preparing artwork for color separation, applying a reliable white underbase, using correct RIP settings, curing and heat press calibration, and regular equipment maintenance to combat Florida’s heat and humidity.

How can brands market Florida DTF trends to Florida consumers and tourism-driven markets?

Market around resort wear, event kits, and coastal lifestyle visuals. Highlight transfer durability and color fidelity in online content, run sampling programs and limited drops, and collaborate with local Florida designers to leverage regional appeal.

Can you share a real-world example of implementing direct-to-film printing within Florida DTF trends?

A Miami boutique used direct-to-film printing to launch a bold tropical capsule with fast turn cycles, social posts showing the transfer process, and margins that benefited from efficient production.

| Section | Key Points |

|---|---|

| Introduction | Florida DTF trends reshape how brands approach printed apparel in a vibrant market; opportunities include Florida’s fashion scene, tourism-driven retail channels, and a growing network of decoration shops adopting DTF workflows; guide covers top trends, what they mean for designers, manufacturers, and retailers, and how to leverage them to grow your business; topics include technology advances, practical tips, and real-world examples. |

| Understanding Florida DTF trends | Florida DTF trends emerge from the convergence of technology, consumer preferences, and regional style; Florida consumers favor bold colors across fabrics; DTF enables vibrant images with soft hand feel, thin weight, and easy customization; essential workflow elements include design to film transfer, color management, and curing; climate influences substrate choice and finishing methods; considerations include fade resistance, wash durability, and fabric compatibility. |

| Technologies powering DTF printing Florida | Key tech improvements include printer hardware, films, and inks enabling high color gamut and detail; white ink reliability is critical for dark fabrics; improved DT film reduces cracking and improves adhesion; color management software and profiles align screen previews with fabric results; practical steps include printer calibration, correct RIP settings, and regular color tests on representative fabrics. |

| Design strategies for Florida DTF prints | Adapt artwork for DTF with emphasis on vector art and clean lines; photographic imagery may require careful color separation and high-resolution files; plan for white underbase on dark garments and transfer margins; favor tropical motifs, beach scenery, sunsets, and bold typography; choose color palettes reflecting coastal vibes; test colors on actual fabrics; practical workflow: design review, print proof, small run before large batches. |

| Production and workflow considerations | Ensure smooth production flow from file prep to film curing; key steps: choose substrate, prepare artwork for color separation, use high-quality white underbase, and maintain a reliable heat press regimen; Florida climate requires regular printer and press maintenance; plans for inventory, dye migration tests, and washing instructions; build strong relationships with film, ink, and transfer paper suppliers. |

| Marketing, branding, and market fit | Marketing translates Florida DTF trends into sales by aligning stories with regional tastes (resort wear, event kits, casual lifestyle); visuals showing transfer process build trust on durability and color fidelity; sampling programs, limited drops, and collaborations with local Florida designers can expand reach; understand price sensitivity to set margins while keeping prints accessible. |

| Case studies and real world examples | Miami boutique bold tropical prints for ready-to-wear capsules; social channels highlight the transfer process; Tampa coastal shop blends photography and graphic art across lightweight tees; resort town retailer tests seasonal motifs reflecting ocean hues and sunsets with fast turn cycles. |

| Future outlook for Florida DTF trends | Continued improvements in printer reliability, film quality, and color management; growing demand for sustainable and customizable apparel; companies investing in training, quality control, and scalable workflows will capture Florida market growth; collaboration with local artists and regional celebrities can accelerate adoption across channels. |

Summary

Florida DTF trends are steering how brands approach printed apparel in a vibrant, sun-soaked market. By embracing Florida DTF trends and direct-to-film technology, brands can achieve bold visuals with a soft hand feel on diverse fabrics. For manufacturers and retailers, aligning product stories with Florida style sensibilities and collaborating with local artists helps optimize margins and shorten lead times. Ultimately, success comes from integrating technology, artistry, and regional flavor across design, production, and marketing to deliver high-quality Florida DTF prints on a reliable schedule.