In the vibrant world of textile printing, the debate between DTF vs Screen Printing is one that businesses often find themselves entangled in. As both methods embrace different techniques, knowing their strengths and weaknesses is crucial when deciding which approach is best for your creative projects. Direct to Film (DTF) printing offers unique benefits, especially for small batches and intricate designs, while the traditional Screen printing process boasts durability and cost-effectiveness for larger runs. In this guide, we’ll explore the DTF printing benefits and how they stack up against the screen printing methodology, providing a comprehensive DTF vs screen printing comparison. Whether you’re an entrepreneur or an artist, understanding these textile printing methods is essential for success.

When selecting a technique for custom apparel printing, you may hear about two distinct options: Direct to Film and the classic Silk Screening process. Each method has its flavors, catering to specific needs depending on the project at hand. Businesses engaged in fashion or promotional items often weigh the pros and cons of DTF and Silk Screening, trying to balance quality, speed, and cost. As we analyze the differences in these printing styles, this discussion will illuminate how Direct to Film’s versatility contrasts with the traditional labor-intensive nature of Silk Screening. Navigating this landscape ensures that your choices align with both your artistic vision and practical requirements.

Understanding Direct to Film Printing (DTF)

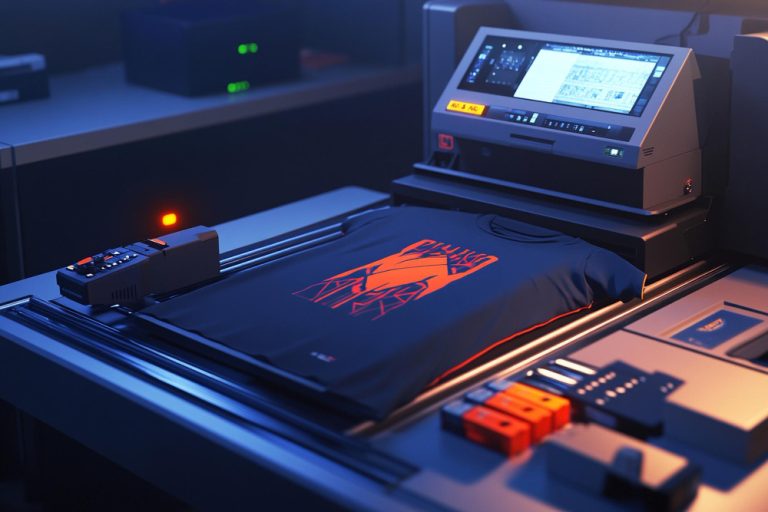

Direct to Film (DTF) printing is revolutionizing the textile industry with its innovative approach that provides vibrant, high-quality prints directly onto films, which are then transferred to fabric. This process involves specialized inks that not only ensure great representation of colors but also allow for intricate designs to be printed with precision. DTF technology thrives on its ability to adapt and produce designs with fine details and gradients, setting it apart from more traditional methods such as screen printing.

Moreover, DTF printing is incredibly versatile, catering to a wide array of fabric types including cotton, polyester, and even blends. This versatility enables businesses to explore a wider product range, from custom apparel to unique promotional items. Given its fast setup and quicker printing capabilities, DTF has emerged as a favorite among businesses looking for efficient solutions without compromising design quality.

The Screen Printing Process Explained

Screen printing is one of the oldest and most reliable methods of textile printing, renowned for its straightforward yet effective process. At its core, this technique involves creating stencils or screens through which ink is pushed onto the fabric, layer by layer, to build up colorful designs. Each color in a design requires a separate screen, which contributes to the complexity of the setup but results in vibrant and durable designs, making it an ideal choice for mass production.

The screen printing process also entails a drying phase post-printing to enhance the longevity and quality of the designs. One of the primary benefits of using screen printing is its cost-effectiveness at higher volumes, as the per-unit cost diminishes significantly. This makes it a preferred method for businesses looking at large orders without sacrificing quality. However, the time and resources required for setup can be a drawback for smaller runs.

Frequently Asked Questions

What are the main differences in the DTF vs Screen Printing techniques?

The main differences between DTF printing and screen printing lie in their processes and application. DTF printing utilizes a heat transfer method where designs are printed onto a film and then transferred to fabric, offering vibrant colors and detailing. In contrast, screen printing involves creating stencils through which ink is applied directly onto the material, producing durable prints but requiring longer setup times for complex designs. Thus, the choice between DTF vs screen printing often depends on specific project needs.

What are the advantages of DTF printing over the screen printing process?

DTF printing offers several advantages over the screen printing process, including greater versatility across various fabrics such as cotton and polyester, the ability to produce intricate designs and color gradients, and quicker setup and execution times, making it ideal for smaller orders. These DTF printing benefits make it a preferred choice for custom apparel, especially when detailed artwork is involved.

How does the durability of prints differ in DTF vs Screen Printing?

In DTF vs screen printing comparison regarding durability, screen printing generally outlasts DTF prints, especially when high-quality inks are used, making them resistant to repeated washing. DTF prints, while offering excellent color and detail, may not hold up as well over time if subjected to heavy wear and wash cycles, resulting in reduced longevity.

Is DTF printing more cost-effective than screen printing for large orders?

In the context of DTF vs screen printing, screen printing tends to be more cost-effective for larger orders due to economies of scale, where the cost per unit decreases significantly with increased quantities. DTF printing, while efficient for small batches, can become more expensive per unit with larger runs, making it less ideal for extensive production needs.

What are the recent trends influencing DTF and screen printing in textile printing methods?

Recent trends affecting both DTF and screen printing include a growing market demand for customization, prompting a rise in DTF printing usage for smaller orders, and advancements in technology enhancing print quality for both methods. Furthermore, sustainability has become a factor, leading to improvements in environmentally friendly practices within both DTF and screen printing techniques.

When should I choose DTF printing over screen printing for my designs?

Choosing DTF printing over screen printing is advisable when your project involves intricate designs with many colors or gradients, requires quick turnaround times, or is a small batch order. The flexibility and detailing offered by DTF printing cater well to customized apparel needs, making it an excellent choice for smaller production runs, whereas screen printing suits larger quantities where durability is paramount.

| Key Aspect | DTF Printing | Screen Printing |

|---|---|---|

| Process | Artwork is printed on a film and transferred to fabric using heat. | Screens are prepared for each color, and ink is pressed through to create the design. |

| Benefits | Versatile on materials, detailed designs, quick setup for small orders. | Cost-effective for large runs, durable prints, vibrant colors. |

| Drawbacks | Less durable for heavy use, higher unit costs for large orders. | Time-consuming setup, limitations on complex designs. |

| Ideal For | Small batches, detailed artwork, quick fulfillment. | Large quantities, high durability requirements, simple designs. |

Summary

When considering DTF vs Screen Printing, each method has distinctive characteristics that fit different printing needs. DTF printing offers vibrant, detailed designs suitable for a range of fabrics and small batch orders, making it an appealing option for businesses seeking flexibility and quick turnarounds. On the other hand, Screen Printing shines in large-scale production, offering cost efficiency and durability that ensure long-lasting prints. Both methods continue to evolve with technological advancements, emphasizing customization and sustainability. Understanding these differences will help you choose the right printing method that best aligns with your project requirements.