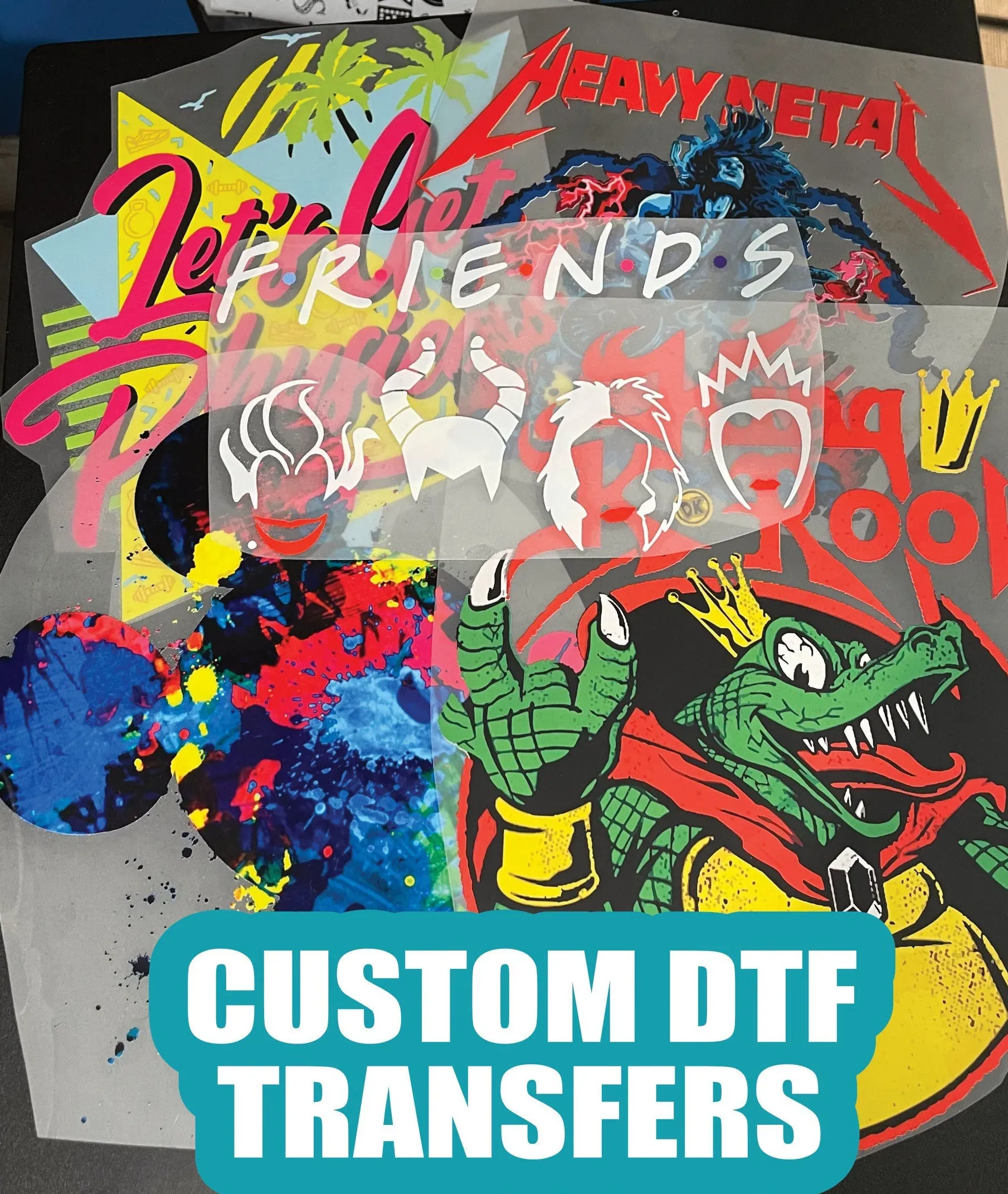

DTF Transfers, or Direct to Film Transfers, are revolutionizing the custom printing landscape, becoming a pivotal choice for those in search of high-quality apparel printing solutions. As the demand for personalized clothing continues to rise, DTF transfers offer an innovative method that combines vibrant colors and intricate designs with unmatched durability. This cutting-edge technology provides a cost-effective alternative to traditional heat transfer printing, making it ideal for print-on-demand businesses and independent creators. With its ability to print on a wide variety of fabrics, DTF transfers are not just a trend; they are shaping the future of custom printing. Join us as we delve into the transformative impact of DTF technology on the industry and discover the reasons behind its rapid ascendancy.

In the realm of personalized apparel, the emergence of Direct to Film (DTF) Transfers has captured attention with its compelling advantages. Also known as direct to film printing, this technique is gaining traction among those looking for efficient methods of custom garment decoration. With increased accessibility in direct film transfer technology, businesses and artists alike can explore versatile options for showcasing their unique designs. The rise of heat transfer methods combined with print-on-demand capabilities signifies a new era in custom printing, allowing creators to deliver exceptional products with remarkable ease. As we explore this innovative approach, its benefits and applications within the fashion industry are becoming ever more evident.

Understanding DTF Transfer Technology

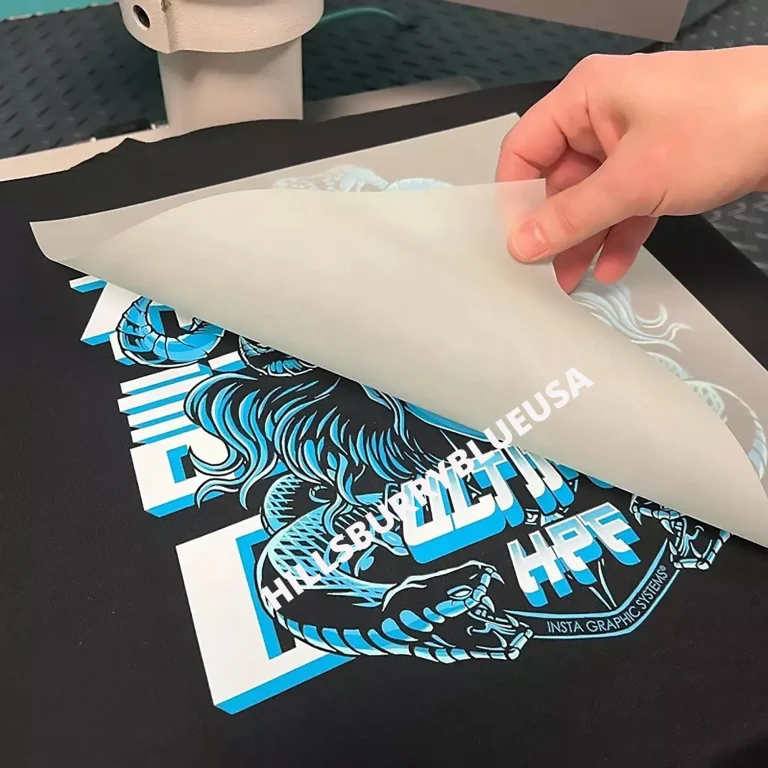

Direct to Film (DTF) printing technology is revolutionizing the custom print landscape by providing an effective alternative to conventional printing methods. Unlike screen printing and vinyl transfers, DTF allows for intricate designs to be printed directly onto a film which is then heat pressed onto fabric. This approach not only enhances the vibrancy of the colors but also captures fine details, making it ideal for producing high-quality custom apparel. With the ability to cater to a vast range of fabrics—from cotton to blends—DTF transfers are fast becoming the go-to choice for businesses looking to diversify their product offerings.

Moreover, the integration of DTF technology in production lines signifies a shift towards more flexible, cost-effective solutions for creators. The workflow is streamlined as it eliminates the time-consuming processes associated with traditional screen printing setups. This efficiency enables businesses, especially those in the print-on-demand sector, to fulfill orders quickly and respond to customer trends in real-time, broadening their market reach in an ever-competitive environment.

Advantages of Direct to Film Printing

One of the significant advantages of DTF printing is its ability to produce high-quality prints with vibrant colors that remain durable through numerous washes. This quality assurance appeals to both casual consumers looking for unique items and businesses aiming to establish strong brand identities through eye-catching apparel. The limitless color and design possibilities allow for intricate artwork to be realized without the hefty price tag typically associated with complex designs in other printing methods.

In addition, the ease of use is another factor drawing attention to DTF technology. Unlike traditional methods, which often require complicated setups and extensive training, DTF printing is accessible even to beginner users. This democratization of technology empowers small business owners and independent designers to craft professional-grade apparel easily, enhancing their ability to compete in the custom printing market.

DTF vs. Traditional Printing Methods

Comparing DTF transfers to traditional printing methods such as heat transfer vinyl and screen printing reveals several key advantages of DTF technology. For instance, while screen printing is limited in color complexity and design intricacy, DTF allows for unlimited colors without additional costs—making it a preferred choice for detailed designs. The reduction in setup time and costs further solidifies DTF’s position as a favorable alternative for businesses of all sizes, from boutique shops to larger apparel manufacturers.

Additionally, DTF technology boasts versatility that outshines other printing techniques. Unlike heat transfer vinyl, which can only be applied to specific materials, DTF transfers can seamlessly adhere to a variety of fabrics. This flexibility enables custom printers to cater to diverse consumer needs, ensuring that they can provide personalized solutions for every demand, whether it be promotional gear or fashion apparel.

The Impact of Innovations in DTF Printing

Innovations in DTF printing technology continue to reshape the custom printing landscape, showcasing a move towards high-quality, efficient, and user-friendly solutions. Companies, like Insta Graphic Systems, have made significant strides with products like the Insta DTF, which emphasize durability and print vibrancy. These advancements collectively reinforce the notion that DTF is not just a passing trend but a foundational technology that is setting the stage for the future of apparel printing.

Moreover, the rise of premium services like those offered by Sam’s DTF Transfers highlights the increasing competitiveness in the DTF market. By providing high-quality transfers and catering to specific market needs, such players are elevating the standard of what consumers can expect from custom printing. As more businesses embrace these innovations, we can expect a continued enhancement in print quality and service delivery across the industry.

Supporting Small Creators with DTF Technology

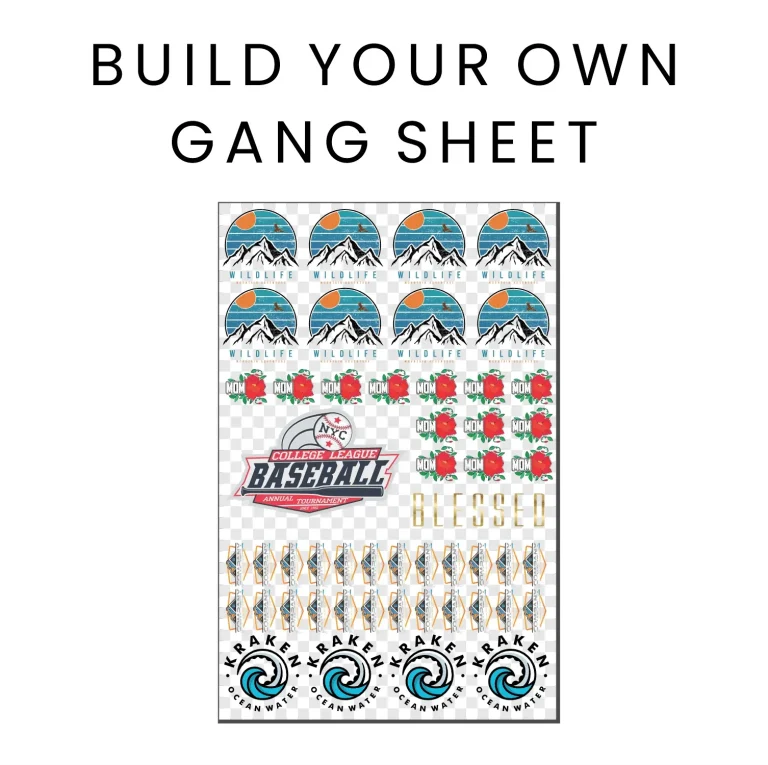

As DTF technology becomes more accessible, it is fostering an environment where small creators and independent designers can thrive. Initiatives such as DTFPrinter’s custom transfer printing service demonstrate a commitment to empowering the creative community. These tailored services offer tools and resources that enable emerging artists to integrate DTF printing into their product offerings without the burden of significant upfront costs. This trend not only diversifies the market but also enriches the artistic landscape by bringing unique creations to life.

Furthermore, the ability to print on-demand aligns perfectly with the needs of small creators who often operate in niche markets. By leveraging DTF technology, they can offer personalized apparel without the risk of overproduction or excess inventory. This flexibility supports sustainable practices while meeting consumer demands for unique, high-quality items that stand out in a saturated market.

The Future of Custom Printing with DTF Transfers

Looking ahead, the future of custom printing is undoubtedly intertwined with the advancements in DTF transfer technology. As consumer preferences shift towards personalization and quality, DTF printing stands ready to meet the demand with its impressive capabilities. The continuous innovation within this space promises enhancements in print technology that will further redefine how custom apparel is designed and manufactured, providing an exciting forecast for businesses and consumers alike.

Moreover, as more industries look for sustainable and efficient printing methods, DTF technology is likely to evolve further. With suppliers increasingly adopting eco-friendly inks and practices, this method could lead the charge towards a new standard in print sustainability. The ongoing development in DTF will not only influence the future of custom apparel but could potentially set a precedent for other sectors within the printing industry, heralding significant changes that prioritize environmental responsibility alongside creative expression.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom printing?

DTF Transfers, or Direct to Film Transfers, are a modern printing technology that enables vibrant designs to be printed directly onto a film and then heat-pressed onto apparel. This method allows for high-quality images and intricate designs on various materials, making DTF a preferred choice in custom printing.

Why are DTF Transfers becoming popular in apparel printing?

DTF Transfers are gaining popularity in apparel printing due to their versatility, cost-effectiveness, and ability to produce vivid, durable prints. Unlike traditional heat transfer printing, DTF allows for unlimited colors and complex designs, making it ideal for custom apparel solutions.

How do DTF Transfers compare to traditional heat transfer printing?

Compared to traditional heat transfer printing, DTF Transfers offer greater design flexibility, faster production times, and superior print quality. DTF does not limit color usage or design complexity, allowing for more creative freedom in custom printing projects.

What advantages do DTF Transfers offer for print-on-demand services?

DTF Transfers are particularly advantageous for print-on-demand services as they allow for quick turnaround times, minimal setup costs, and the ability to handle small runs efficiently. This makes DTF an optimal choice for businesses looking to cater to individual custom requests.

Are DTF Transfers environmentally friendly for custom printing?

Yes, many companies utilizing DTF Transfers are adopting eco-friendly inks and materials, enhancing sustainability within the custom printing industry. This aligns with growing consumer demands for environmentally conscious printing solutions.

What types of materials can DTF Transfers be applied to in custom apparel printing?

DTF Transfers can be applied to various materials, including cotton, polyester, and blends, making them suitable for a wide range of apparel items, from t-shirts to tote bags, enhancing their versatility in custom printing.

| Key Points | Details |

|---|---|

| Emergence of DTF Transfers | DTF printing provides a strong alternative to traditional methods like screen printing due to its versatility, cost-effectiveness, and efficiency. |

| Versatility | Can be used on various materials including cotton, polyester, and blends for products like T-shirts and tote bags. |

| Cost-Effectiveness | Requires less expensive equipment and setup, reducing overhead for small businesses and creators. |

| Efficiency | Allows quicker turnaround times, ideal for boutique shops and on-demand services. |

| Key Developments and Innovations | New products from companies like Insta Graphic Systems and AM.CO.ZA highlight DTF’s growing accessibility and quality improvements. |

| New Services for Creators | Services tailored for small creators have emerged, making it easier to incorporate DTF technology into projects. |

| Key Benefits of DTF Transfers | High-quality, vibrant prints; unlimited color/design options; ease of use; and sustainable practices are driving its popularity. |

Summary

DTF Transfers are revolutionizing the custom printing landscape, making them the preferred choice for modern apparel production. With their ability to deliver stunning, high-quality prints on a variety of materials, coupled with cost-effectiveness and speed, DTF technology is reshaping how businesses approach custom printing. This innovative method not only simplifies the printing process for creators but also supports sustainability efforts, meeting today’s consumer demands for eco-friendly products. As we move forward, the rise of DTF Transfers will undoubtedly continue to influence and enhance the capabilities of custom printing, offering endless possibilities for both small entrepreneurs and established brands.