In the ever-evolving world of custom apparel, DTF transfers have emerged as a revolutionary printing method that rivals traditional techniques like screen printing. Direct-to-Film (DTF) printing offers the ability to create high-quality graphics on a variety of fabrics, making it an enticing option for businesses looking to elevate their garment decoration game. With the growing demand for personalized items, DTF transfers provide unmatched versatility and intricate design capabilities that satisfy modern consumer tastes. In this article, we will explore why DTF printing is rapidly gaining popularity and how it stacks up against conventional screen printing in terms of print quality and cost-effectiveness. Join us as we dissect these printing methods to help you make informed choices in the realm of custom apparel.

When it comes to apparel printing techniques, the conversation often revolves around alternatives such as transfer printing and traditional screen methods. Direct-to-Film (DTF) transfers represent a contemporary solution that is reshaping the landscape of garment decoration. Unlike the more established screen printing process that may limit design intricacies, DTF technology allows users to achieve stunning, photorealistic prints with remarkable ease. As we navigate through the capabilities and innovations surrounding these printing methods, we will illuminate the advantages of utilizing DTF transfers in creating personalized apparel that meets today’s market demands.

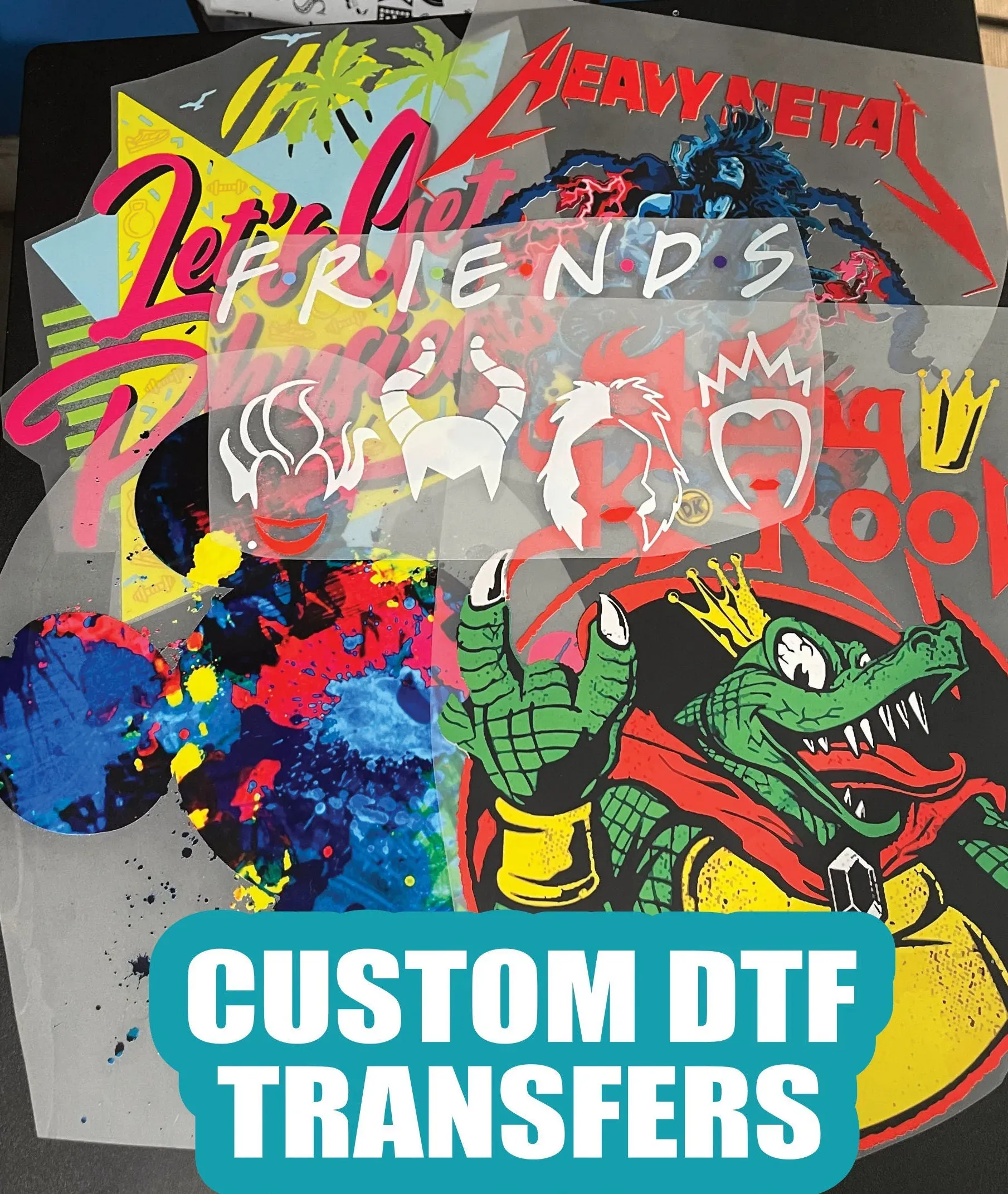

Understanding DTF Printing and Its Benefits

DTF printing, or Direct-to-Film printing, offers a plethora of benefits that are revolutionizing the custom apparel industry. This method allows for the transfer of intricate designs onto various fabrics with remarkable accuracy and detail, unlike traditional methods. One of the most significant advantages of DTF printing is its ability to produce high-quality images that pop with color and clarity, making it an ideal choice for businesses looking to create standout merchandise. Additionally, DTF printing eliminates the need for a color separation process, which can be time-consuming and costly in screen printing.

Furthermore, DTF transfers are increasingly favored for their versatility. This technique can be applied to a wide range of materials, including cotton, polyester, and blends without the need for additional treatments. As a result, brands can diversify their product offerings while keeping production streamlined. The technology behind DTF printing continues to evolve, ensuring that the prints remain vibrant and durable even after many washes. In an era where personalization is key, DTF printing provides a flexible solution for creating custom designs that cater directly to consumer preferences.

Exploring Screen Printing: A Traditional Approach

Screen printing has long been a staple in the garment decoration industry, known for its ability to produce bold and vibrant designs. The technique involves using a stencil, or screen, to apply ink onto fabric, making it especially effective for large batches of visually striking prints. This method excels in situations where fewer colors are needed, as it can achieve high levels of saturation and color richness efficiently. Screen printing is well-loved among brands aiming to create a more straightforward visual impact without intricate details.

However, screen printing does come with its share of limitations. For instance, producing designs with multiple colors or fine details requires multiple screens and a more complex setup process. This can drive up costs and turnaround times, making it less suitable for smaller runs or highly customized orders. Additionally, the environmental impact of screen printing must be noted, as it often uses more substantial amounts of ink and treatments compared to DTF printing. Nevertheless, screen printing remains a popular choice for many businesses, especially when it comes to larger orders where efficiency is key.

Print Quality: A Key Comparison Between DTF and Screen Printing

When it comes to print quality, direct-to-film transfers have emerged as a game changer in the custom apparel market. DTF transfers excel at reproducing photorealistic images and intricate designs with a high level of detail and color vibrancy. This is particularly valuable for brands that require a fine touch in their merchandise, as the output can rival traditional methods while often minimizing the risk of color fading over time. The soft feel of DTF prints on fabric further enhances wearability, providing a smooth finish that customers appreciate.

Conversely, while screen printing can produce high-quality results for solid designs, it may not match the detail achievable with DTF. This limitation is especially noticeable when dealing with complex patterns or gradients, which can appear less sharp with screen printing. Many businesses are now prioritizing print quality as a vital selling point, leading to increased interest in DTF technologies that promise superior outcomes. Understanding these differences can help companies make informed decisions about which printing technique to employ based on their specific needs.

Cost Considerations: DTF Transfers vs. Screen Printing

Cost is often a deciding factor for businesses when choosing between DTF transfers and screen printing. While screen printing can be less expensive for bulk orders, it typically requires a minimum order quantity, which can be a barrier for small brands or personalized items. DTF printing, on the other hand, shines in its ability to accommodate smaller runs economically. This flexibility allows businesses to fulfill customer orders without incurring prohibitive costs, making it a favorable choice for start-ups and companies focused on custom designs.

Additionally, with advancements in DTF technology, the cost of production continues to decrease as efficiency improves. This has led many companies to recognize DTF as a more viable option in terms of both quality and expense. For businesses exploring the custom apparel market, weighing the initial investment against long-term benefits will be crucial when deciding which printing method aligns better with their financial goals and production capabilities.

Technological Innovations Shaping DTF Printing

The landscape of DTF printing is constantly evolving, driven by technological innovations that enhance print capabilities. For instance, recent advances in ink formulations and printing equipment have significantly improved the color range and durability of DTF transfers. Companies are now able to produce prints that withstand the rigors of daily wear and washing without sacrificing visual appeal. This heightened level of reliability has made DTF printing a go-to choice for many garment decorators seeking quality that meets modern consumers’ demands.

Moreover, automated printing processes and pre-treatment advancements have streamlined production and reduced turnaround times. As a result, businesses can now offer a wider variety of custom options to their customers, catering to the increasing demand for personalization in the market. With innovations continuing to emerge, DTF printing is poised to redefine the standards of excellence in the garment decoration industry, enabling brands to capitalize on consumer preferences and stay ahead of the competition.

The Future of Custom Apparel: DTF Transfers vs. Screen Printing

The future of custom apparel is actively being shaped by the growing popularity of DTF transfers. As consumers increasingly seek unique and personalized products, the adaptability and high-quality outputs of DTF printing meet these rising expectations effectively. Traditionally, screen printing has dominated the market; however, as awareness of new technologies spreads, more brands are considering DTF as a viable alternative. This shift suggests that DTF may soon establish itself as a standard method for customized garment decoration.

In conclusion, while both DTF printing and screen printing have their respective benefits, the trend seems to favor the innovations offered by DTF. Companies that embrace these advancements not only enhance their production capabilities but also position themselves to meet the new demands of the marketplace. By understanding the evolving landscape of custom printing methods, businesses can choose the best fit for their operations, ensuring their products continue to resonate with consumers seeking quality, flexibility, and originality.

Frequently Asked Questions

What are DTF transfers and how do they compare to screen printing?

DTF transfers, or Direct-to-Film transfers, are a modern printing method that allows for high-quality and detailed designs to be printed onto fabrics. Unlike screen printing, which uses stencils to apply ink, DTF printing involves printing onto a special film that is then heat-pressed onto the garment. This enables DTF transfers to produce photorealistic prints with vibrant colors, making them ideal for custom apparel that requires intricate designs.

What are the advantages of DTF printing for garment decoration?

DTF printing offers several advantages for garment decoration, including superior print quality, the ability to work on various fabric types, and reduced setup times. It excels in reproducing intricate designs and colors, making it a favorite among businesses that require high-detail custom apparel. Additionally, DTF allows for smaller print runs without sacrificing quality, which is often a limitation in traditional screen printing.

How does the print quality of DTF transfers compare to screen printing?

The print quality of DTF transfers is generally higher than that of screen printing, particularly for complex designs and photorealistic images. DTF printing can produce vivid colors and detailed images due to its unique process, whereas screen printing may struggle with fine details and gradients. This makes DTF transfers a preferred choice for custom apparel that seeks to make a strong visual impact.

Are DTF transfers more cost-effective than screen printing for small orders?

Yes, DTF transfers are often more cost-effective than screen printing for small to medium orders. Screen printing typically requires a minimum quantity for cost efficiency, which can be prohibitive for smaller businesses or custom runs. DTF allows for affordable printing of small batches without the extra costs associated with setting up screens for each color, making it ideal for personalized or one-off designs.

Which printing method is more versatile: DTF transfers or screen printing?

DTF transfers are more versatile than screen printing, as they can easily be applied to a wide variety of fabrics, including cotton, polyester, and blends. This adaptability means that DTF printing is suitable for different types of custom apparel and merchandise without the complexities and limitations faced by screen printing, which often requires specific surfaces and set conditions.

What technological advancements have improved DTF printing recently?

Recent technological advancements in DTF printing have focused on enhancing print capabilities and efficiency. Innovations include improved printing machinery that increases production speed and quality, better inks that yield vibrant colors and durable prints, and enhanced heat transfer technologies. These developments have made DTF printing a more competitive alternative to traditional methods like screen printing, particularly for high-quality custom apparel.

| Aspect | DTF Transfers | Screen Printing |

|---|---|---|

| Versatility | Excels in versatility; compatible with various fabrics including cotton, polyester, and blends. | Limited fabric compatibility; requires specific surfaces. |

| Quality of Print | Produces higher resolution and photorealistic prints ideal for detailed designs. | Effective for bold designs but struggles with intricate artwork. |

| Process Complexity | Less complex; eliminates the need for multiple screens and simplifies production. | More complex; requires creating screens for each color, involving multiple steps. |

| Cost-Effectiveness | More cost-effective for low to medium quantities; ideal for personalized items. | Generally requires minimum order quantities, making it less ideal for small runs. |

Summary

DTF Transfers are increasingly recognized as a superior method for custom printing in the competitive world of apparel. This comparison highlights the advantages of DTF technology, particularly its versatility, exceptional print quality, simplified processes, and cost-effectiveness for small to medium orders. As businesses strive to meet growing consumer demands for personalized and high-detail garments, DTF Transfers poised to redefine the standards of garment decoration, making it an informed choice for anyone venturing into custom apparel printing.