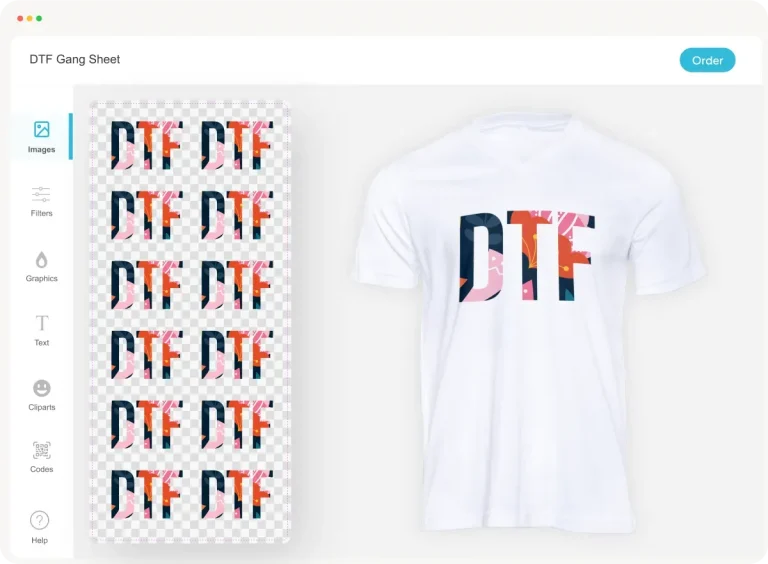

DTF transfers are redefining how brands achieve quick, durable customization on everyday garments. As DTF printing trends evolve, designers can push complex artwork onto more fabrics with less waste. This approach fuels personalization in apparel by enabling low-volume drops and region-specific designs. For retailers and studios exploring production options, DTF transfers support efficient custom apparel printing without heavy upfront costs. Advances in DTF technology advancements and direct-to-film printing innovations are expanding color fidelity and film-library flexibility, empowering scalable customization.

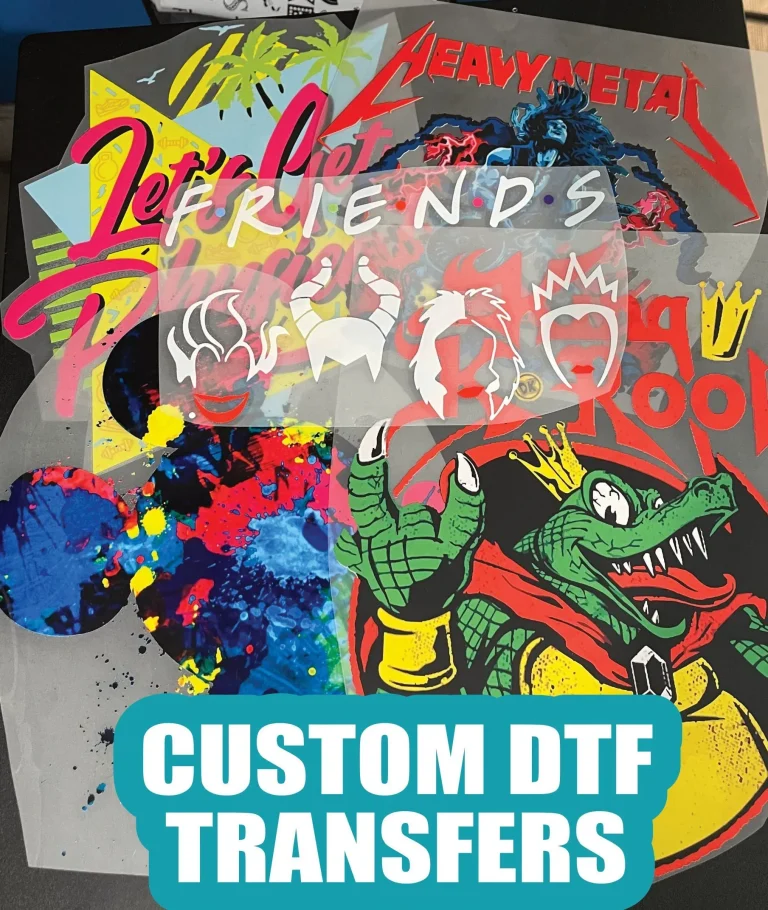

Seen through a broader lens, the same capability is described as film-to-fabric printing, print-on-film processes, or heat-press textile decoration. The concept centers on transferring a vibrant image from a coated PET film to fabric via adhesive and heat, delivering durable results across blends and cottons. This LSI-friendly framing highlights related technologies such as polymer-coated films, ink systems, and heat-press automation that support on-demand production. In this sense, the DTF workflow becomes a flexible, scalable method for brand storytelling, regional drops, and limited-edition collaborations.

DTF transfers: Driving direct-to-film printing innovations for modern apparel personalization

DTF transfers are at the forefront of direct-to-film printing innovations that empower brands to deliver high-energy visuals across a wide range of fabrics. As inks, films, and adhesive chemistries improve, the result is vibrant, durable prints that stay vivid through multiple washes. This evolution aligns with current DTF technology advancements, enabling on-demand production, limited drops, and scalable customization without the high setup costs of traditional methods. For fashion labels and makers, this means a practical path to personalized product drops that feel crafted for the individual consumer.

The core advantage of DTF transfers lies in flexibility. With broader fabric compatibility—from cotton to blends and performance fabrics—and improved color management, brands can deploy multi-layer designs and intricate artwork with relative ease. As a result, DTF transfers support custom apparel printing at smaller batch sizes while preserving fidelity and hand feel. This is a direct reflection of the broader DTF printing trends that favor fast iterations, limited editions, and regional designs that resonate with local audiences.

Practical implications for brands and printers are clear: invest in reliable presses, high-quality films, and optimized curing workflows, and you unlock faster prototyping and reduced inventory risk. The streamlined end-to-end workflow—from design through to heat-press finishing—enables quick-turn personalization at scale, aligning with the industry move toward on-demand manufacturing and smarter color management.

DTF printing trends and personalization in apparel: Strategies for scalable custom apparel printing with technology advancements

As consumer appetite for unique items grows, DTF printing trends show a clear path to mass customization that doesn’t require mass inventories. The ability to produce one-off items or small-lot drops makes custom apparel printing economically viable for independent brands, retailers, and artist collaborations. By embracing DTF technology advancements, designers can experiment with seasonal graphics, regional motifs, and co-created artwork while maintaining high fidelity and fast turnaround times.

The role of personalization in apparel continues to expand as technology lowers the barriers to entry for smaller teams. Advances in color accuracy, print resolution, and substrate compatibility enable more precise reproductions of complex artwork, from photo-realistic images to multi-color gradients. Direct-to-film printing innovations also enable consistent results on dark fabrics and blends, broadening the scope of what can be produced in-house or through selective outsourcing. This confluence of DTF printing trends and personalization drives a new era of custom apparel printing, where design intent meets scalable production.

Looking ahead, brands that pair robust color management with smart workflow automation will maximize the value of DTF technology advancements. The combination of improved films, better curing solutions, and intuitive software lowers reprints and waste, reinforcing the business case for on-demand, regionally targeted collections. In this landscape, the terms DTF technology advancements and direct-to-film printing innovations are not just technical notes—they’re the levers behind faster time-to-market, higher consumer engagement, and sustainable growth in the custom apparel printing space.

Frequently Asked Questions

What are the latest DTF transfers trends and how do they support personalization in apparel?

DTF transfers enable brands to personalize apparel at scale by supporting small-batch production, rapid prototyping, and customization on a wide range of fabrics. The latest DTF printing trends focus on higher resolution, broader fabric compatibility, and streamlined workflows, empowering designers to deliver unique garments quickly and efficiently. This directly supports personalization in apparel by letting consumers buy items that feel custom without long lead times.

How do DTF technology advancements impact custom apparel printing for small to mid-sized brands?

DTF technology advancements—such as improved inks, film quality, and smarter heat-press integration—enhance durability, color accuracy, and production efficiency for custom apparel printing. Direct-to-film printing innovations lower setup costs and expand fabric compatibility, enabling small and mid-sized brands to offer on-demand drops and limited editions with consistent quality.

| Aspect | Key Points |

|---|---|

| Definition | DTF transfers are direct-to-film transfers: prints on PET film using specialized inks, then heat-pressed onto textiles to produce a durable, vibrant finish. |

| Process steps | Print on PET film with specialized inks, apply adhesive powder, cure, and heat-press onto fabric. |

| Key advantages | Broad fabric compatibility; simpler multilayer designs; relatively low setup costs for small to mid-sized runs; favorable for on-demand, limited editions. |

| Personalization trends | Consumers want unique, limited-edition items; supports small batches and regional/collaborative designs; aligns with mass customization. |

| Technology role | Improvements in print resolution, color accuracy, and speeds; inks bond to cotton, blends, polyester; smarter heat-press and color-management software. |

| Ecosystem fit vs DTG/Screen | DTF balances strong performance on dark fabrics with scalable production, complementing DTG on light fabrics and screen printing for large runs. |

| Sustainability and efficiency | On-demand, just-in-time production reduces waste; energy-efficient curing; better color management reduces reprints and costs. |

| End-to-end personalization pipeline | Design to delivery: color management, pre-press checks, film creation, adhesive application, curing, and heat-press; automation lowers variability. |

| Fabric compatibility and care | Adheres to cotton, blends, polyesters, and some performance fabrics; educate customers on care to preserve vibrancy and longevity. |

| Practical implications for brands/printers | Lower minimums, faster prototyping, personalized drops; invest in reliable presses and film; test across fabrics; maintain curing. |

| Color management and design | Calibrated color profiles, fabric-aware separations, and a color library to ensure consistency across batches. |

| Quality control and durability | Durable bond with resistance to cracking/peeling; set wear thresholds; QC at pre-print, post-coat, and post-press stages. |

| Operational efficiency and economics | Flexible batch sizes lower inventory risk; track costs per unit (film, ink, adhesive, energy) and optimize pricing; enables collaboration. |

| Supply chain resilience and digital integration | Cloud-based design repositories, standardized formats, and automated order management enable multi-channel scale and quick pivots on disruption. |

| Implementation tips | Start with a small pilot; invest in quality film/inks/press; create care instructions; build a color library; partner with experienced printers. |

| The big picture | Future points toward mass customization with better inks, smarter heat-press tech, and design tools that speed the pipeline, expanding fabric support and speed. |

Summary

DTF transfers are at the heart of the shift toward personalization in apparel. By embracing the latest DTF technology advancements, brands can offer tailored designs, rapid prototyping, and scalable customization that meet modern consumer expectations. The interplay between DTF printing trends, personalized product strategy, and efficient production workflows will determine which brands lead in a world where customer-centric fashion is the norm. Whether you’re launching a limited-edition line or rolling out a regional collection, DTF transfers provide a practical, high-quality pathway to deliver apparel that feels uniquely designed for every customer.