DTF transfers, or Direct to Film transfers, represent a groundbreaking way to achieve vibrant, high-quality prints directly on fabric. As manufacturers and enthusiasts alike adopt this innovative printing method, understanding how to maximize its potential becomes essential for creating perfect DTF prints. Whether you’re a seasoned pro or just starting out, grasping the nuances of DTF printing can elevate your designs and broaden your creative horizons. In this guide, we’ll explore beginner tips for DTF that will help you master this technique and ensure your prints stand out. Join us as we delve into the key aspects of direct to film printing and its benefits over traditional methods.

Transitioning to popular alternatives in the custom printing world, you may encounter terms like film transfer printing or transfer film techniques. These methods share similarities but differ in their applications and material compatibility. The technology behind film transfer processes combines artistry with practicality, allowing creators to achieve stunning results on various fabrics. For those looking to explore the advantages of such printing techniques, understanding the fundamentals of vibrant DTF prints will provide a solid foundation. In this discussion, we will uncover the essentials required to get started and succeed in the captivating realm of fabric printing.

Understanding the Basics of DTF Printing

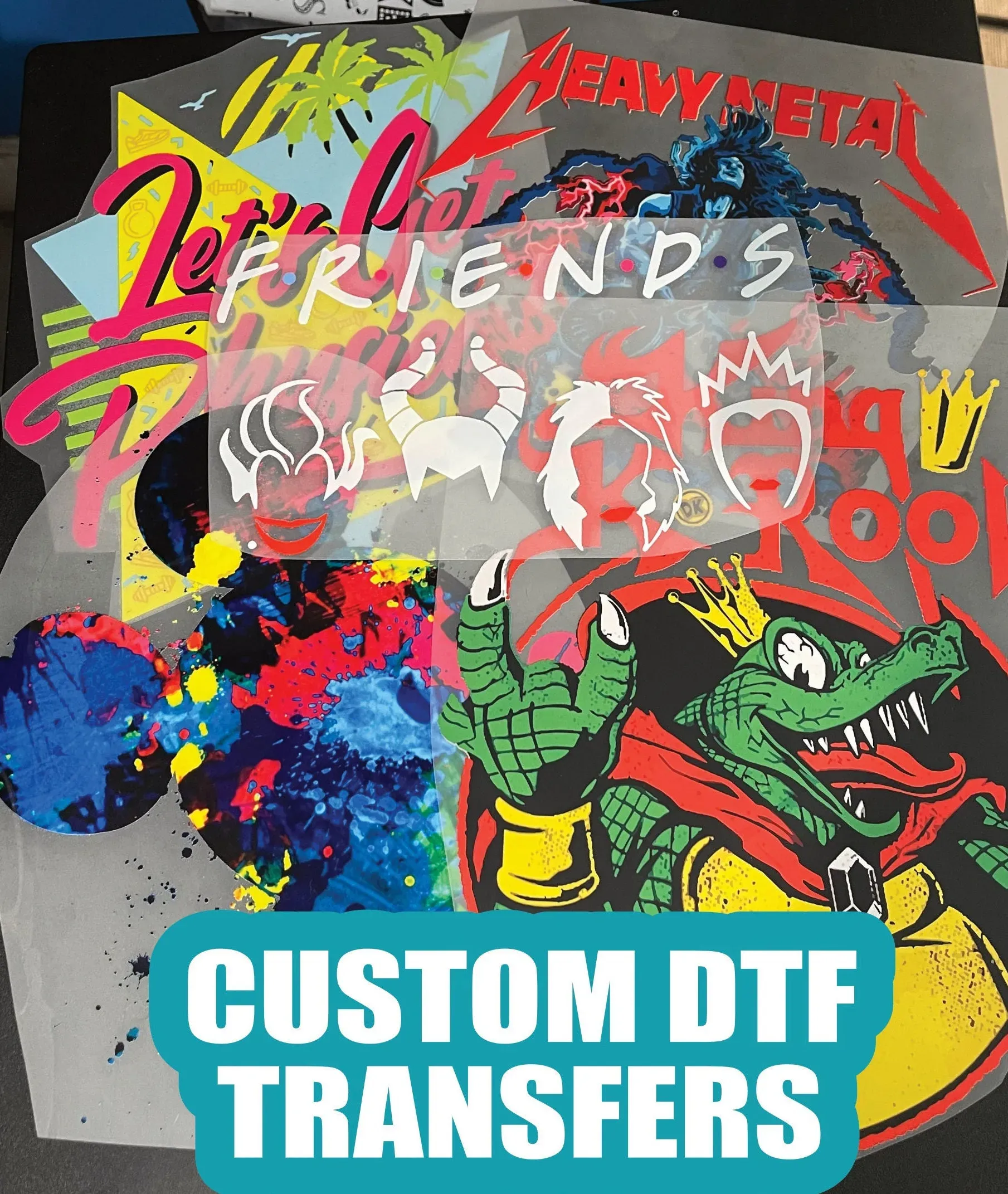

DTF printing, or Direct to Film printing, is a modern method that allows for the seamless transfer of designs onto various fabric types. It offers benefits that traditional printing methods might not provide, such as enhanced color vibrancy and durability. One of its unique aspects is the ability to achieve ‘gang sheets’, enabling multiple designs to be printed on the same sheet, ultimately maximizing both efficiency and material usage.

This technology operates by printing onto a special transfer film that is then applied to the fabric using a heat press. The inks used in DTF printing are specially formulated to be vibrant and long-lasting, giving apparel a professional quality that is highly desirable. For beginners, grasping these fundamental aspects of DTF printing is essential to leverage its full potential in creating stunning custom designs.

Key Equipment Needed for Successful DTF Transfers

Investing in the right equipment is crucial for achieving perfect DTF prints. Primary among these is the DTF printer, which needs to be capable of handling specific DTF inks to ensure vibrant and long-lasting results. Additionally, ensuring that your printer is properly calibrated can help avoid common printing errors like misalignment and color discrepancies.

In addition to the printer, selecting high-quality transfer films and compatible DTF inks is paramount. The use of premium materials elevates the overall quality of output, making the designs not just visually appealing but also durable. Choosing the correct tools can significantly impact your printing outcomes and is a vital step for both beginners and seasoned professionals.

Best Practices for DTF Printing Setup

Setting up your workspace for DTF printing requires attention to detail to produce quality results. This starts with printer calibration, which aligns the printer’s settings with the specifications of your transfer films and inks. Proper calibration minimizes the risk of common errors such as misalignments and ensures that colors are accurately represented.

Moreover, adjusting the temperature and pressure settings on your heat press is necessary to achieve optimal transfer results. Experimenting with various settings ensures that you find the right combination for different fabric types—too low of a temperature can cause poor adhesion while too high can damage the material. Being methodical in your setup process is vital for consistent and quality DTF transfers.

Preparing Your Designs for Perfect DTF Transfers

Design preparation is a critical step that directly affects the quality of your DTF prints. Ensuring your designs are in the correct size and resolution is essential, as anything less could lead to pixelation or distortion during transfer. Additionally, engaging with designs that favor high contrast and solid colors can enhance vibrancy in the final output.

Utilizing design software effectively to cater to DTF printing standards can make a significant difference. By creating designs that consider the technical limitations and capabilities of DTF printing, you set yourself up for success. A well-prepared design not only saves time and materials but also results in a professional finish that stands out.

Advantages of DTF Transfers Over Other Printing Methods

Comparing Direct to Film printing with other techniques, such as sublimation, reveals several unique advantages that DTF offers. One of the most compelling benefits is versatility; DTF printing works well on a variety of fabric types beyond just polyester, making it an excellent choice for diverse applications and a broader customer base.

Furthermore, the color vibrancy achieved through DTF printing often surpasses that of other methods. This quality makes it particularly appealing for custom apparel where bright, true colors are essential. As the landscape of printing technology evolves, DTF holds a prominent place, particularly for businesses seeking to provide high-quality outputs across different fabric types.

Emerging Trends and Innovations in DTF Technology

The DTF printing industry is undergoing rapid changes, with ongoing innovations designed to enhance production efficiency. Notable advancements include the introduction of large-format printers that increase output speed and reduce waste, allowing for a more streamlined workflow. Companies are investing in new technologies that aim to simplify the setup process and further improve print quality.

Participating in trade shows and industry events helps enthusiasts and professionals alike stay informed about the latest developments in DTF technology. Such innovations signal a promising future for the field, where creativity meets advanced printing capabilities, and where anyone interested in custom apparel can leverage the latest tools to achieve perfect results.

Frequently Asked Questions

What are the steps to achieve perfect DTF prints?

To achieve perfect DTF prints, start by calibrating your DTF printer to avoid misalignments. Use high-quality transfer films and DTF inks to enhance color vibrancy. Adjust your heat press settings for temperature and pressure before transfers, and conduct test runs to fine-tune techniques on different fabrics. Lastly, prepare your designs carefully, focusing on resolution and color contrast.

What is the advantage of direct to film printing over sublimation?

The primary advantage of direct to film (DTF) printing over sublimation is its versatility. DTF printing works on a wider range of fabrics, not just polyester as sublimation does. Additionally, DTF prints are known for their vibrant colors and superior durability, making them ideal for various custom apparel applications.

How should I set up my equipment for DTF transfers?

To set up your equipment for DTF transfers, ensure you have a calibrated DTF printer compatible with specialized inks. Use high-quality PET films designed for DTF printing. Adjust your heat press to the correct settings based on the fabric type you are working with. Proper equipment setup is crucial for achieving quality DTF prints.

What are some beginner tips for DTF printing?

Beginner tips for DTF printing include properly calibrating your printer, using only high-quality materials like transfer films and inks, and adjusting heat press settings accurately. Conducting test transfers on different fabric types is also essential, as well as preparing your design with optimal resolution and solid colors for better print quality.

Why is the quality of transfer films important in DTF printing?

The quality of transfer films is vital in DTF printing because it directly impacts the vibrancy and durability of the final prints. High-quality PET films ensure better ink adhesion and enhance the color richness of your designs, leading to more professional and long-lasting results compared to cheaper alternatives.

What innovations are currently shaping the future of DTF transfers?

Current innovations in DTF transfers include advancements in large-format printing technologies by companies like EazyDTF, aimed at improving production efficiency. Innovations also focus on enhancing print quality and reducing turnaround times, as showcased at industry events like FESPA. These advancements are set to further elevate the quality and creativity of DTF printing.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | DTF printing revolutionizes fabric printing, popular among enthusiasts and professionals. |

| What is DTF Printing? | Transfer of printed designs from film to fabric with vibrant colors and durability. |

| Key Equipment and Material Requirements | Includes DTF printer, quality transfer films, and specialized DTF inks. |

| Setting Up for Success | Calibration, high-quality materials, correct temperature/pressure, test runs, design preparation. |

| DTF vs. Other Transfer Methods | DTF is more versatile and achieves vibrant colors compared to sublimation. |

| Ongoing Innovations in DTF Technology | Rapid advancements improving production efficiency and quality outputs. |

Summary

DTF Transfers are changing the landscape of custom apparel printing by offering an innovative solution for transferring designs onto fabrics. This method ensures vibrant colors, exceptional durability, and versatility across different fabric types, making it an attractive choice for both hobbyists and professionals. By leveraging high-quality materials and equipment alongside precise setups, anyone can achieve stunning prints. As technology advances, the potential for DTF transfers continues to grow, providing exciting opportunities for creative expression in printing.