DTF transfers, or Direct-to-Film transfers, represent a revolutionary advancement in custom apparel printing. This innovative technique utilizes textile printing technology to produce stunning and detailed designs on various fabrics, making it a preferred choice for those who seek personalized garment printing. By seamlessly combining efficiency and quality, DTF transfers enable businesses to cater to a growing demand for unique apparel without the high costs typically associated with traditional printing methods. Furthermore, as sustainable printing methods gain traction, DTF transfers stand out for their use of eco-friendly, water-based inks, reducing environmental impact significantly. In this guide, we will delve into the intricacies of DTF transfers, exploring their process, advantages, and the burgeoning trends shaping the future of textile printing.

Direct-to-Film printing, an alternative term for DTF transfers, has swiftly become a staple in the realm of fabric decoration. This avant-garde printing method allows for an exceptional application of vivid graphics onto diverse materials, tailored specifically for custom garment production. Thanks to its adaptability, businesses have embraced this technique for creating personalized garments that meet the unique tastes of today’s consumers. Emerging as a leader in textile printing technology, this method not only enhances creativity but also aligns with the rising preference for sustainable production practices. Exploring the fundamentals of this method reveals how DTF can streamline operations while providing high-quality outputs.

What Are DTF Transfers and How Do They Work?

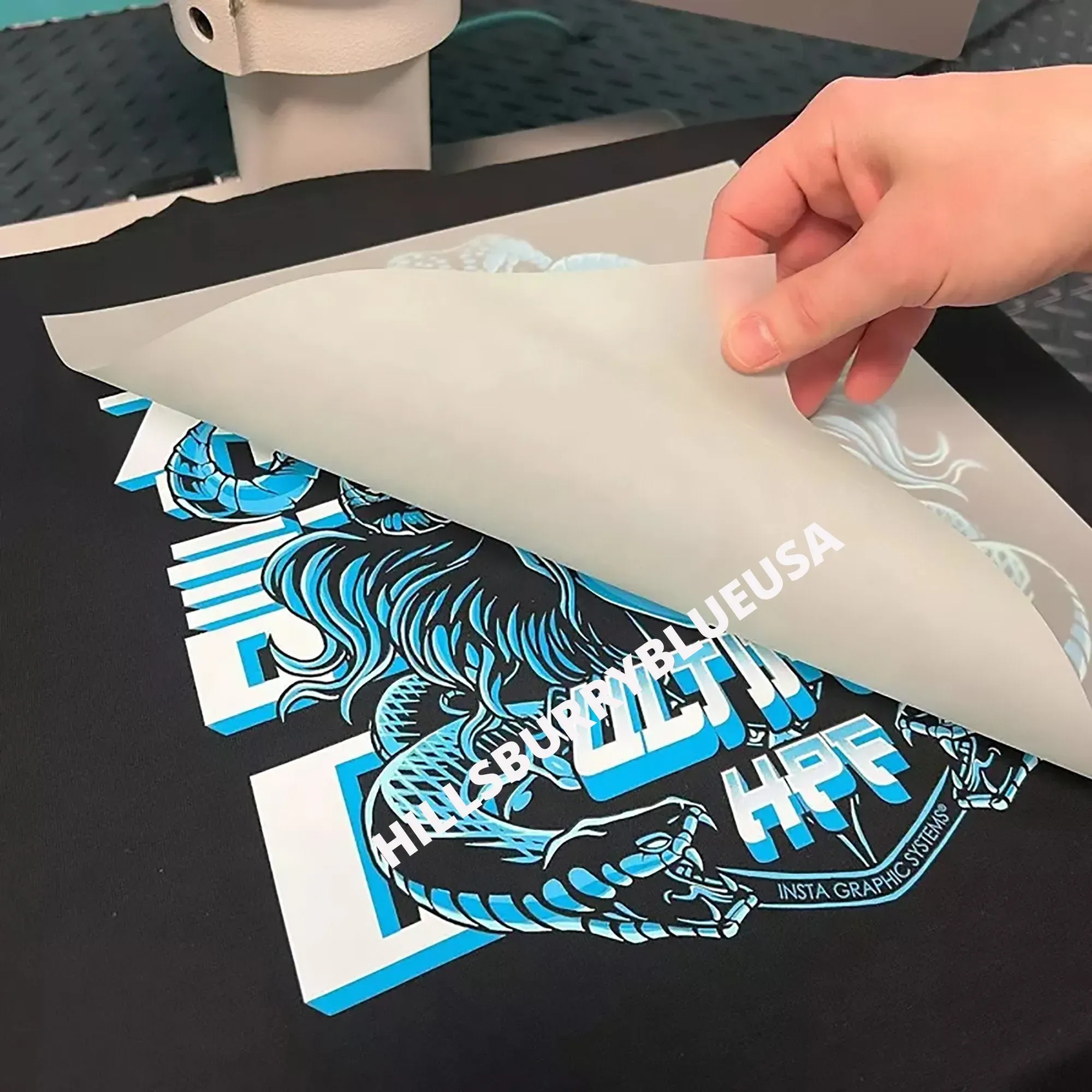

Direct-to-Film (DTF) transfers have revolutionized the textile printing industry by providing a versatile and efficient method for applying colorful graphics to fabric. The process begins with high-quality digital artwork that is printed onto a special release film using eco-friendly, water-based inks. Once printed, an adhesive powder is applied to the film, creating a bond that ensures vibrant colors shine brightly on the final product. The film is then heated and pressed onto the chosen fabric, allowing for a permanent and durable design that retains its integrity even after multiple washes.

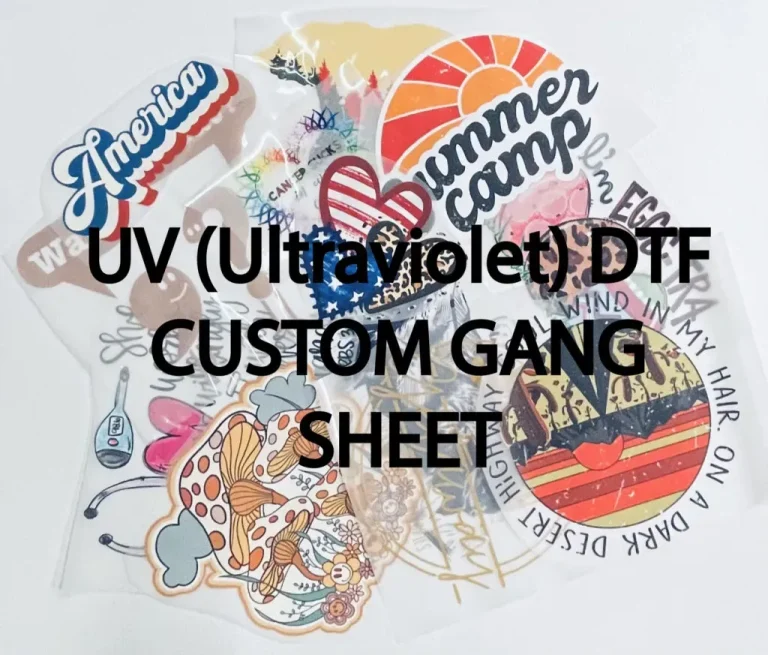

DTF printing stands out from traditional methods like screen printing and Direct-to-Garment (DTG) printing, particularly in terms of its ease of use and material compatibility. It allows for direct application to a broad range of fabrics including cotton, polyester, and their blends. This adaptability makes DTF printing a preferred choice among custom apparel producers looking to provide diverse options for their clientele, catering to both fashion trends and individual preferences.

The Advantages of DTF Printing Compared to Traditional Methods

One of the key benefits of DTF transfers is the cost-effectiveness for small production runs. Unlike traditional screen printing, which often requires extensive setup costs and is labor-intensive, DTF offers a streamlined process that enables businesses to produce smaller quantities without incurring high overheads. This affordability, combined with the ability to quickly adapt designs, allows brands to experiment with personalized garments, meeting the increasing consumer demand for unique, custom apparel.

Additionally, the DTF method is mindful of environmental impact, utilizing water-based inks that significantly reduce the release of harmful chemicals typically associated with traditional printing processes. This sustainable approach not only attracts eco-conscious brands but also fosters a positive image among consumers who prioritize environmentally friendly practices when choosing their apparel.

Essential Equipment for DTF Transfer Printing

Setting up a successful DTF transfer printing operation necessitates the proper equipment to ensure high-quality outcomes. The cornerstone of any DTF business is a specialized DTF printer, designed to deliver vibrant colors and precision in printing. These printers utilize advanced technology to create detailed graphics that stand out on fabric, making them crucial for achieving professional-grade results.

In addition to a DTF printer, a reliable heat press is essential for transferring the design onto textile materials. A good heat press ensures that the correct temperature and pressure are applied uniformly, which is vital for proper adhesion and durability. Lastly, graphic design software plays a critical role in preparing files for printing, allowing designers to create eye-catching visuals that can easily be customized for different products and styles.

Emerging Trends in the DTF Industry

The DTF printing industry is rapidly evolving, propelled by trends that emphasize customization and sustainability. Consumers are increasingly gravitating towards custom apparel that features unique designs tailored to their tastes, pushing businesses to adopt DTF technology that easily accommodates these requests. This movement towards personalization is reshaping the retail landscape and enabling brands to differentiate themselves in a crowded market.

Moreover, the demand for on-demand production has surged alongside the growth of e-commerce. DTF printing allows retailers to fulfill orders quickly without the stress of maintaining inventory, which effectively reduces fabric waste and aligns with sustainable practices. As more businesses recognize the benefits of DTF technology, we can anticipate increased market competition and a wider range of offerings that cater to diverse consumer preferences.

Challenges and Considerations for DTF Printing

Despite its numerous advantages, DTF printing presents challenges that businesses must navigate carefully. One prevalent issue is the durability of the transfers; if the heat pressing is not done correctly, there may be problems with adhesion, resulting in designs peeling or fading over time. It is essential for printers to understand the nuances of heat settings and application techniques to ensure long-lasting results, which can impact customer satisfaction and loyalty.

Additionally, businesses must contend with robust competition from other printing methods, particularly Direct-to-Garment (DTG) printing, which may still be preferred for larger, high-volume orders. This necessitates a thorough evaluation of specific business needs and market demands to choose the most suitable printing technique. By staying informed about industry advancements and customer preferences, businesses can strategically position themselves to thrive.

Looking Ahead: The Future of DTF Transfers

The future of DTF transfers appears optimistic as innovation continues to drive the industry forward. Ongoing advancements in printing technology are enhancing the speed, quality, and efficiency of DTF operations, making them increasingly desirable for businesses aiming to provide high-quality custom garments. These improvements not only streamline the production process but also bolster the capability to meet the evolving demands of consumers.

As the market for personalized garment printing expands, we can expect a rising interest in DTF techniques. Retailers and entrepreneurs adopting DTF printing will likely benefit from the increasing consumer preference for unique styles and sustainable practices. The synergy of technology and market desires positions DTF transfers at the forefront of the textile printing revolution, promising a vibrant and dynamic future for the industry.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film using water-based inks. An adhesive powder is applied to the printed film, and the design is heated and pressed onto various fabrics. This technique facilitates vibrant graphics on custom apparel, making it a popular choice for personalized garment printing.

What are the environmental benefits of using DTF transfers for textile printing?

DTF transfers utilize water-based inks, which significantly reduce harmful substances typically associated with traditional plastisol inks used in other printing methods. This eco-friendly approach aligns DTF with sustainable printing methods, making it a preferable option for businesses focused on environmentally conscious practices.

How do DTF transfers compare to other printing methods like DTG and screen printing?

DTF transfers offer greater flexibility and lower setup costs compared to screen printing, making them ideal for small batch runs. Unlike DTG printing, DTF can work on a broader range of materials, including cotton and polyester blends, enhancing its application in personalized garment printing. Both DTF and DTG serve different market needs, depending on volume and design complexity.

Can DTF transfers be applied to any fabric types, and what are the most suitable materials?

Yes, DTF transfers can be applied to a variety of fabrics including cotton, polyester, and blends. This versatility empowers designers to experiment with different textile types and enhances the appeal of custom apparel printing, as it allows for vibrant designs on various garments.

What equipment is necessary to start a DTF printing operation?

To set up a DTF printing operation, you’ll need a specialized DTF printer, a heat press for applying designs onto fabrics, and graphic design software to create and prepare your designs. This equipment is essential for ensuring high-quality output in your custom apparel printing projects.

What trends are shaping the future of DTF transfers in the textile printing industry?

Key trends influencing the DTF transfer market include an increasing demand for customization, on-demand production capabilities, and a focus on sustainable practices. As consumers seek personalized products and businesses adopt eco-friendly practices, DTF transfers are poised for significant growth and innovation in custom apparel printing.

| Aspect | Details |

|---|---|

| Understanding DTF Transfers | A technique where designs are printed onto special film, which adheres to fabric after applying powder adhesive and heat. |

| Key Mechanics | High-quality graphics are printed on transfer film, followed by adhesive application and heat transfer to fabric. |

| Advantages | 1. Cost-effective for short runs. 2. Compatible with various materials. 3. Environmentally friendly due to water-based inks. |

| Equipment Needed | 1. Specialized DTF printer. 2. Heat press for applying design. 3. Graphic design software. |

| Trends | 1. Rising demand for customization. 2. On-demand production capabilities. 3. Emphasis on sustainable practices. |

| Challenges | 1. Durability issues if improperly processed. 2. Competition from other printing methods like DTG. |

| Future Outlook | Promising advancements in technology, with potential market growth in custom apparel using DTF techniques. |

Summary

DTF transfers represent a revolutionary approach in the textile printing industry, enabling high-quality and vibrant designs to be printed on various fabrics. This innovative technique not only supports customization and personalization but also aligns with modern sustainability goals, making it an appealing choice for businesses and consumers alike. As advancements in technology continue and consumer preferences shift towards unique, eco-friendly products, DTF transfers are poised to significantly grow in the custom apparel market. Understanding the nuances and capabilities of DTF transfers can empower retailers and designers to offer appealing products while maintaining high standards of print quality and sustainability.