DTF transfers packaging is an essential process in ensuring the longevity and quality of your Direct to Film transfers. With their growing popularity in the garment printing industry, it becomes paramount to adopt proper techniques for storing DTF transfers effectively. Utilizing best practices in packaging DTF transfers helps to safeguard against fading, smudging, or damage caused by improper handling. In this guide, we will explore various strategies for preserving DTF transfers and the importance of maintaining optimal storage conditions. By focusing on DTF transfer storage solutions, you can ensure vibrant and high-quality results in your printing projects.

When it comes to Direct to Film transfer preservation, proper storage and packaging play a crucial role in maintaining design integrity. As the textile printing landscape evolves, understanding the nuances of effective DTF transfer protection becomes increasingly important. From selecting appropriate containers to implementing strategies that mitigate environmental risks, the right practices will ensure that your transfers remain in premium condition. This article will delve into the best methods for ensuring the safe keeping of your transfers, covering everything from humidity control to container selection. With these insights, you’ll be equipped to enhance both the quality and durability of your garment prints.

Optimal Conditions for Storing DTF Transfers

To achieve the best results when using DTF transfers, it is imperative to store them under optimal conditions. The ideal storage temperature for these transfers should fall between 60°F and 75°F (15°C to 24°C). If the temperature rises above this range, the adhesive used in the transfers may begin to weaken, leading to poor application results or even transfer failures. Conversely, storing them in colder environments can make the transfers brittle, which increases the risk of cracking or breaking during application.

Furthermore, humidity is another critical factor in preserving the integrity of DTF transfers. Excess humidity can cause moisture to seep into the transfers, leading to issues such as ink bleed, film sticking, and ultimately, application failure. To maintain peak quality, it is advisable to store DTF transfers in humidity levels below 50%. This creates the perfect environment for ensuring the longevity of your designs.

Choosing the Best Packaging for DTF Transfers

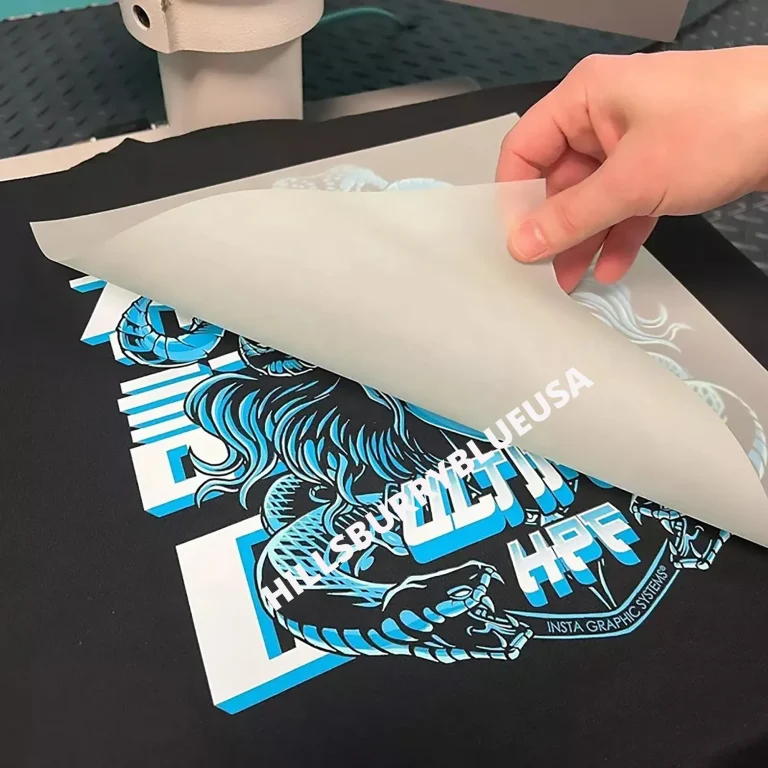

The packaging of DTF transfers plays a vital role in their preservation. One effective method is to use plastic bags made from polyethylene or PVC to encase individual transfers. These materials not only keep the transfers safe from dust and moisture but also provide a lightweight and transparent barrier that allows for easy visibility. It is crucial to choose bags that are appropriately sized to prevent excess movement inside, which could lead to damages.

In addition to utilizing plastic bags, incorporating a sturdy cardboard backing is equally important. This method ensures that the transfers remain flat and rigid during storage or transit, preventing them from bending or crumpling. By selecting the appropriate packaging materials, you significantly enhance the protection of your DTF transfers from external environmental factors.

The Importance of Separating DTF Transfers

When storing DTF transfers, it is essential to keep different designs or color types separated. This practice prevents the transfers from sticking to one another, which could compromise their quality and vibrancy. A simple and effective solution is to place thin sheets of paper or plastic as separators between individual transfers. This helps maintain their pristine condition while also making them easier to handle when preparing for application.

By utilizing separators, you also reduce the risk of scratches and damages that can occur when multiple transfers are stored together. This simple technique enhances the usability and longevity of each transfer, allowing for smoother application processes and better overall results in your garment printing projects.

Protecting DTF Transfers from Sunlight

Exposure to UV light is one of the most significant threats to the longevity of DTF transfers. Prolonged sunlight exposure can lead to degradation of the ink and transfer medium, resulting in faded colors and diminished quality. Hence, it is of utmost importance to store your DTF transfers in dark, cool locations whenever possible.

If your storage area exposes the transfers to natural light, consider wrapping them in opaque materials. This will shield them from harmful UV rays while also helping to maintain their overall quality. Ensuring proper protection from sunlight not only preserves the vibrancy of the colors but also enhances the durability of the transfers throughout their storage life.

Clear Labeling Techniques for DTF Transfers

Effective labeling is a crucial aspect of organizing DTF transfers to ensure smooth workflow and inventory management. By clearly labeling each package, you can include vital information such as transfer design, contents, and production date. This practice promotes the transparent organization of your stock, enabling you to track inventory efficiently.

Implementing the First In, First Out (FIFO) method through labeling helps minimize waste by encouraging the usage of older transfers first. In addition, this avoids the pitfalls of using outdated stock, which may not deliver optimal results. Thus, maintaining a clear labeling system is essential for maximizing the usability of your DTF transfers.

Transporting DTF Transfers Safely

If you need to transport your DTF transfers for a client meeting or a trade show, it is essential to take extra precautions to ensure their safety. Utilizing sturdy, rigid boxes can provide significant protection for the transfers during transit. These boxes should be appropriately sized to prevent unnecessary movement that could lead to damage during transportation.

In addition to secure packaging, incorporating cushioning materials like bubble wrap or foam inserts can further safeguard your DTF transfers. By cushioning them properly within the box, you can minimize the risk of bending or breaking during transport. Adopting these transport considerations means your DTF transfers will arrive in perfect condition, ready to impress your clients or audience.

Frequently Asked Questions

What are the best practices for packaging DTF transfers to maintain their quality?

To maintain the quality of DTF transfers, it’s essential to use polyethylene bags for moisture protection, incorporate cardboard backing to keep transfers flat, and store them in a cool, dry environment away from sunlight and humidity.

How should I store my DTF transfers to prevent damage?

Store your DTF transfers in a cool location with a temperature between 60°F and 75°F and keep humidity levels below 50% to prevent degradation. Additionally, use separators between different designs to avoid sticking.

Why is humidity control important for DTF transfer storage?

Humidity control is critical for DTF transfer storage as excess moisture can cause issues like film sticking during application. Keeping humidity levels below 50% will help maintain the integrity and effectiveness of your DTF transfers.

What materials should I use for protecting DTF transfers during transport?

When transporting DTF transfers, use rigid boxes for protection and include cushioning materials like bubble wrap to prevent movement and potential damage during transit.

Can DTF transfers be preserved from sunlight exposure?

Yes, to preserve DTF transfers from sunlight exposure, always store them in opaque packaging or a dark location. This minimizes UV damage, which can fade colors and degrade the quality of the transfers.

How can I effectively organize and label my DTF transfers?

To effectively organize DTF transfers, use clear labels indicating the contents, design, and production date. This helps manage inventory better and ensures that older stock is used first, maintaining transfer quality.

| Key Aspect | Best Practices |

|---|---|

| Optimal Storage Conditions | Store between 60°F – 75°F (15°C – 24°C) and maintain humidity below 50%. |

| Choosing the Right Packaging Materials | Use polyethylene or PVC bags and include cardboard backing. |

| Separating Transfers | Utilize thin sheets of paper or plastic as separators. |

| Protecting from Sunlight | Store in dark places or wrap in opaque materials. |

| Effective Labeling | Label packages with design details and production dates. |

| Transport Considerations | Use rigid boxes and cushioning materials for safe transport. |

Summary

DTF transfers packaging plays a crucial role in ensuring the longevity and quality of the prints. Proper packaging and preservation techniques safeguard your transfers against environmental factors that can cause fading, smudging, or even transfer failure. By implementing best practices such as maintaining optimal storage conditions, utilizing suitable packaging materials, ensuring UV protection, and practicing effective labeling, you can guarantee that your DTF transfers deliver vibrant and high-quality results every time. Remember, investing time in proper packaging today not only protects your transfers but also enhances your garment printing success in the future.