DTF transfers for beginners open up a forgiving path to durable, vibrant designs on a wide range of fabrics. This approachable guide covers DTF printing basics, focusing on the essential steps, tools, and surfaces you’ll encounter. From selecting a compatible printer and the right film to applying adhesive powder and setting up the heat press, the guide emphasizes a practical, reproducible workflow. You’ll learn how to prepare garments, manage a white underbase when needed, and troubleshoot common issues that affect adhesion and color accuracy. By starting with simple designs and documenting your settings, you’ll build confidence and steadily improve your results.

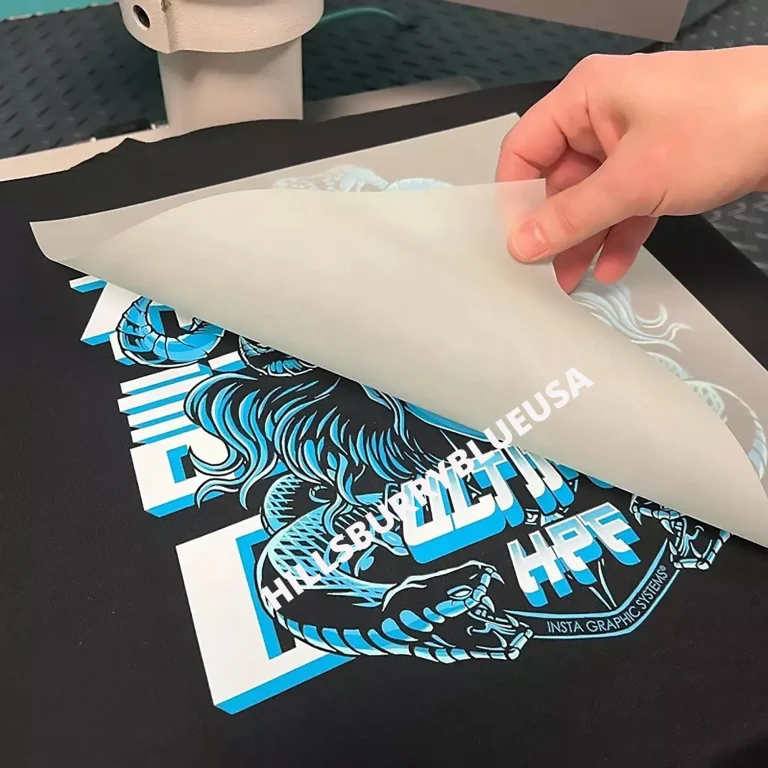

As an alternative framing, this method is often described as direct-to-film transfers or film-based color applications for apparel. In practice, the process involves printing a design onto a clear film with white underbase capabilities, applying an adhesive powder, and using a heat press to embed the image into the garment. This LSI-informed approach connects with broader topics like substrate compatibility, color management, and post-transfer care to ensure durability. If you’re comparing options, considering factors like ink coverage, powder adhesion, and curing strategies helps align this method with other fabric printing techniques.

DTF transfers for beginners: Essential setup and fundamentals

DTF transfers for beginners rely on a straightforward workflow that emphasizes consistency. Start with a dedicated printer capable of white ink, then choose DTF film that provides good ink capture and clear transparency. Pair this with the appropriate adhesive powder and a curing method so the film bonds correctly during transfer. By anchoring your setup to DTF printing basics, you’ll achieve reliable color depth on a wide range of fabrics.

Next, refine your color management and design prep to prevent common issues. Calibrate your monitor to your printer profile, ensure the white underbase is dense enough for dark fabrics, and test print before a full run. When problems arise, apply DTF transfer troubleshooting steps—check film handling, verify DTF ink and powder adhesion, and confirm proper heat press settings and dwell times to maintain color accuracy and durability.

DTF printing basics and troubleshooting for designers

Understanding DTF printing basics is the backbone of any successful project. Focus on how a compatible DTF film interacts with a white-ink-capable printer, the role of DTF ink and powder in forming a durable bond, and how heat and pressure affect transfer quality. When you align these elements, you can deliver vibrant, soft designs that hold up across washes.

To boost throughput while preserving quality, set up a repeatable process. Use alignment aids, experiment with light and heavy powder coatings, and test different curing times to minimize ghosting. Keep a lab notebook of temperatures, dwell times, and fabric types so you can track what works best, and use DTF transfer troubleshooting practices to quickly identify and fix color or adhesion issues. Also, keep DTF film clean and properly stored to prevent dust or moisture from affecting the print.

Frequently Asked Questions

What are the essential tools and materials you need for DTF transfers for beginners?

To start with DTF transfers for beginners, gather the core tools: a DTF printer with white ink capability, DTF film sheets, adhesive powder, and a reliable method to cure the powder (heat dryer, heat gun, or oven). You’ll also need a heat press, and garment-prep supplies like pre-press sheets, silicone or Teflon sheets, and a clean, ventilated workspace. Optional aids include an alignment jig and a dedicated curing device. This setup aligns with DTF printing basics and provides a solid foundation for consistent, high-quality transfers.

How can I troubleshoot common issues in DTF transfers for beginners?

Common DTF transfer troubleshooting for beginners includes issues like color fading, powder not adhering, edge ghosting, sticky film, and dull tones. Quick fixes: ensure the powder is fully cured and the printed film is dry before curing; apply adhesive powder evenly and remove excess; verify uniform heat and pressure on the heat press; use protective sheets to prevent edge curling; and refine color management and printer calibration. Run test prints to dial in white underbase density and ink/powder balance. These steps follow DTF printing basics and help prevent repeat problems.

| Section | Key Points |

|---|---|

| Introduction | DTF transfers enable full-color designs on a wide range of fabrics using a DTF system (printer with white ink, DTF film, adhesive powder, heat press). They yield soft, durable transfers suitable for small businesses, crafters, and DIY projects; the method combines affordability with versatility. |

| Tools & Materials | Key equipment: DTF printer with white ink capability; DTF film sheets; DTF adhesive powder; powder curing/drying setup; heat press; garment preparation tools; cleaning and safety gear; optional workflow aids to improve alignment and efficiency. |

| Setup / Workflow | 1) Prepare design and color management; 2) Print onto DTF film with white underbase as needed; 3) Apply adhesive powder evenly; 4) Cure the powder; 5) Prepare the garment with pre-press; 6) Transfer to fabric using proper heat, pressure, and peel; 7) Post-press care and wash tests to verify durability. |

| Design considerations & best practices | Use high-quality artwork with proper resolution; optimize white underbase density; balance ink and powder; ensure alignment with marks or jigs; consider fabric type and adjust heat/pressure/dwell time accordingly. |

| Troubleshooting | Fading colors after washing: cure/adjust powder; powder not adhering: cure properly and clean surface; edge adhesion issues: ensure uniform pressure; sticky film: under-curing or heat; color separation issues: calibrate printer and color management; run test prints. |

| Tips for ongoing improvement | Start with simple designs; document temperature, times, and powder usage; invest in alignment tools and better heat-press accessories; engage with community for tips and profiles. |

Summary

DTF transfers for beginners describe a practical pathway to creating durable, full-color designs on apparel with a streamlined workflow. By focusing on the core tools and steps—printer with white ink, DTF film, adhesive powder, curing method, and a reliable heat press—you build a solid foundation for reliable results. Start with careful design and color management, print and cure consistently, and you’ll see improvements with every project. As you gain experience, you can explore fabric variations, finish options, and more advanced techniques, expanding your skills and confidence in DTF printing.