DTF Transfers for Beginners opens a practical doorway to a versatile garment decoration technique that blends design flexibility with a straightforward production workflow. Understanding the DTF printing process helps you predict results and choose fabrics that perform well with the technique. In this beginner guide, you’ll pick up DTF design tips to ensure crisp edges, clean color, and a comfortable white underbase for darker fabrics. We’ll also cover heat press settings for DTF so you can translate artwork onto textiles with reliable adhesion and vibrant finish. Along the way, you’ll learn DTF powder adhesion basics and practical DTF transfer troubleshooting steps to reduce misprints and wasted materials.

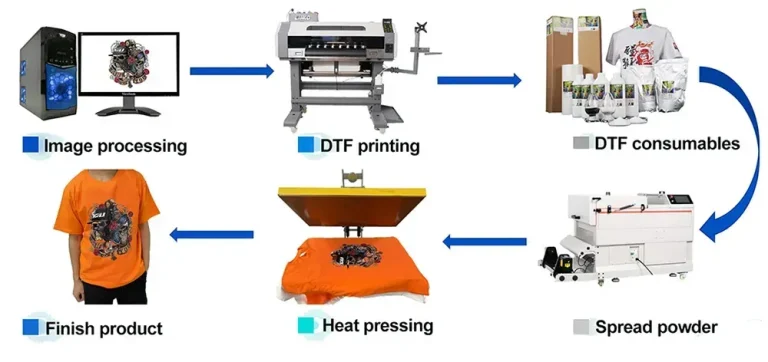

From a broader viewpoint, the direct-to-film workflow uses printable film and a bonded adhesive powder, then applies heat and pressure to bond the image to fabric. This modern garment decoration approach shares DNA with other transfer methods while offering flexible color reproduction and compatibility with a wide range of fabrics. For newcomers, think of it as a film-based transfer system that combines design freedom, careful material management, and a repeatable press sequence. By focusing on the core steps—preparing artwork, coating the film, and achieving clean heat transfer—you build confidence without getting overwhelmed. As you grow, you can explore color management, substrate testing, and troubleshooting strategies that keep your results consistent across projects.

DTF Transfers for Beginners: From Design to Final Print

DTF Transfers for Beginners maps out a practical path from concept to a tangible garment print. By focusing on the DTF printing process, you can translate artwork into vibrant transfers with predictable results. Emphasize solid design tips, proper resolution, and clear color separation to ensure your first projects are crisp and durable, even before you start testing on fabrics.

As you move through the workflow, you’ll encounter key steps that affect final quality, including preparing the artwork, printing on DTF film, applying adhesive powder, and curing it before transfer. Mastery of DTF powder adhesion and an understanding of heat press settings for DTF are essential to prevent ghosting, sizzling, or uneven transfer areas. This foundational approach helps beginners build confidence and repeatable results.

Mastering the DTF Printing Process: Design, Color Management, and Troubleshooting

This subheading highlights how thoughtful design intersects with the technical side of the DTF printing process. Leveraging DTF design tips—such as starting with high-resolution images, using transparent backgrounds for light fabrics, and adding a white underbase for dark textiles—helps ensure vibrant, accurate color reproduction and sharp edges. A color-managed workflow and careful ICC profiling also support consistency across devices and materials.

Beyond design, the journey includes refining heat press settings for DTF, managing color fidelity, and addressing common issues through DTF transfer troubleshooting. Troubleshooting topics like powder adhesion, underbase visibility on dark fabrics, and edge sharpness are integral to improving reliability. By pairing precise heat, time, and pressure with robust powder adhesion control, you’ll reduce failures and achieve repeatable, professional-looking transfers.

Frequently Asked Questions

DTF Transfers for Beginners: What is the DTF printing process and how can I optimize heat press settings for DTF on different fabrics?

DTF Transfers for Beginners: The DTF printing process involves printing your design on DTF film, applying a hot-melt adhesive powder, curing the powder, and then transferring the image to fabric with a heat press. For beginners, start with the film and powder manufacturer’s recommended heat press settings for your material, and adjust based on fabric type (cotton, blends, or synthetics). Always run a test print to dial in temperature, time, and pressure. Pay special attention to DTF powder adhesion—ensure an even coating and thorough curing to prevent flaky transfers.

DTF Transfers for Beginners: What are common DTF transfer troubleshooting steps and how do DTF design tips and DTF powder adhesion influence the final result?

Common DTF transfer troubleshooting includes checking color management and ICC profiles to prevent color mismatch, verifying that a white underbase prints correctly on dark fabrics, confirming powder adhesion and proper curing, and ensuring accurate alignment to avoid misregistration. DTF design tips help prevent issues by guiding you to use vector graphics for crisp edges, maintain safe margins, and plan a reliable white underbase for dark fabrics. DTF powder adhesion is critical: apply a uniform layer and cure thoroughly; poor adhesion or uneven curing is a frequent cause of peeling or cracking and can degrade color and durability.

| Section | Core Point | Why It Matters | Practical Tip |

|---|---|---|---|

| Introduction to DTF Transfers for Beginners | DTF is a flexible garment decoration method with design flexibility and a straightforward workflow tailored for beginners. | It offers a clear learning path from concept to final print and helps set expectations for beginners. | Start with simple designs and practice the full workflow to build consistency. |

| What Are DTF Transfers and Why They Matter for Beginners | The process uses a printed film coated with hot-melt adhesive powder, then transferred onto fabric via a heat press; works on cotton, blends, and dark textiles with proper settings. | Understanding the process helps predict results and avoid common mistakes. | Test on swatches, verify film and powder compatibility, and consider fabric type when selecting settings. |

| DTF Design Tips | Use high-resolution artwork (300 dpi or higher); design with a transparent background for light fabrics or a white underbase for dark fabrics; include vector graphics for logos and plan color separations. | Design quality impacts edge sharpness, color vibrancy, and transfer durability. | Keep important details away from edges, plan a white underbase for dark fabrics, and save files as PNG with transparency or TIFF with consistent color settings. |

| Equipment, Materials, and Setup | A beginner-friendly kit includes a CMYK printer, DTF film, hot-melt adhesive powder, a curing unit, a heat press, and protective sheets. | Having reliable, compatible components supports learning and repeatable results over time. | Invest in dependable gear and create a simple, repeatable workflow instead of chasing every new gadget. |

| From Design to Final Print: A Step-by-Step DTF Workflow | 8-step process: prepare design, print on film, apply adhesive powder, cure, prep for transfer, perform the transfer, peel and cool, and post-transfer care. | A consistent workflow reduces errors and yields reliable, high-quality transfers. | Verify alignment, ensure proper curing, and follow fabric-specific heat, time, and pressure guidelines. |

| Troubleshooting Common DTF Issues | Common issues include color mismatch, weak or missing white underbase on dark fabrics, blurry edges, poor powder adhesion, and peeling after transfer. | Addressing issues early saves material and improves final results. | Calibrate color management, ensure even powder application, and adjust heat, pressure, and dwell times for the fabric in use. |

| Tips for Beginners | Practical quick wins include testing on inexpensive garments, documenting settings, starting with 1–2 core colors, and checking film/powder compatibility. | Structured practice builds accuracy and confidence in the DTF workflow. | Maintain equipment, create a color-management checklist, and log temperatures, times, and pressures for different fabrics. |

| Maintenance, Care, and Scaling Your DTF Capabilities | Regular maintenance includes cleaning film paths and platens, inspecting moving parts, and replacing worn components as you scale. | Scaling helps improve efficiency while preserving quality across more fabrics and designs. | Consider a dedicated printer, stronger curing equipment, and a larger heat press as volumes grow, while re-checking powder adhesion and color calibration. |

| Conclusion | This topic distills the essentials of turning designs into durable DTF transfers. | A solid blend of design tips, a reliable DTF printing process, and thoughtful heat press settings drives consistent results. | Persist with practice, document outcomes, and expand your repertoire to more complex designs and fabrics for ongoing progress. |

Summary

DTF Transfers for Beginners offers a practical path to mastering a versatile garment decoration method. By focusing on solid design tips, a reliable DTF printing process, and thoughtful heat press settings for DTF, you’ll produce vibrant, durable transfers with confidence. This guide emphasizes a repeatable workflow, careful material selection, and proactive troubleshooting to minimize errors. As you practice, you’ll gain greater control over color management, timing, and pressure, enabling you to tackle more complex designs and fabrics. With patience and consistent practice, DTF Transfers for Beginners becomes a foundation for expanding your skills in modern garment decoration.