DTF transfers, or Direct-to-Film transfers, are revolutionizing the custom apparel industry by offering an innovative solution for vibrant and durable designs. This advanced printing technology allows for incredible versatility, accommodating various fabrics and ensuring that each creation retains its quality even after multiple washes. Whether you’re a small business or an individual looking to personalize clothing, understanding how DTF transfers work is essential for achieving stunning results without the need for specialized equipment. The benefits of DTF printing are numerous, including high-quality images and cost-effectiveness, making it an appealing option among alternatives like direct-to-garment (DTG) printing. Dive into the world of DTF printing technology, and discover how it can elevate your custom apparel projects to new heights.

In the dynamic realm of fabric printing, Direct-to-Film (DTF) applications stand out as a contemporary choice for enhancing textile designs. Also referred to as DTF technology, this method is praised for its ability to produce high-resolution graphics and its compatibility with a myriad of materials, such as cotton and synthetics. By utilizing this cutting-edge printing approach, creators are able to achieve exceptional results with minimal setup requirements, making custom apparel accessible and efficient. As the industry evolves, the advantages of DTF prints over traditional methods become increasingly evident, prompting many to explore this innovative medium. The increasing popularity of custom transfers highlights the creativity and personalization DTF printing can bring to the fashion landscape.

Understanding the DTF Printing Process

DTF transfers, or direct-to-film transfers, represent a revolutionary approach in the world of custom apparel printing. In essence, this technique involves applying ink directly onto a specially designed PET film, which is later used to transfer vibrant designs onto various fabric types. This method not only enhances the detail of prints but also provides a vivid color palette, ensuring that the final output is both eye-catching and resistant to fading. The process typically starts with high-resolution design printing onto the PET film, followed by the application of adhesive powder and a heat-curing process to ensure durability.

One of the standout features of DTF printing technology is its accessibility. Unlike traditional methods such as screen printing or direct-to-garment printing, DTF does not require extensive setup or specialized equipment. This allows small businesses and hobbyists to take advantage of this process without incurring substantial costs. By mastering the basics of DTF printing, anyone can create custom apparel that meets modern fashion standards, thereby tapping into a lucrative niche in the garment industry.

Benefits of Using DTF Transfers for Custom Apparel

The surge in popularity of DTF transfers in custom apparel can be attributed to numerous benefits that the process offers. For starters, one of the most significant advantages is its versatility; DTF printing can be applied to virtually any fabric, including challenging materials such as nylon and leather. This feature opens doors for designers to experiment with a diverse range of fabrics, expanding their creativity and allowing for unique apparel solutions that cater to various markets.

Moreover, the durability of DTF transfers sets them apart from other printing methods. Unlike traditional prints that may fade or crack after several washes, DTF designs are known to withstand over fifty wash cycles without significant deterioration. This durability makes it an excellent choice for sportswear and frequently laundered garments, ensuring that custom designs remain intact and vibrant over time.

The Application Process for DTF Transfers Made Simple

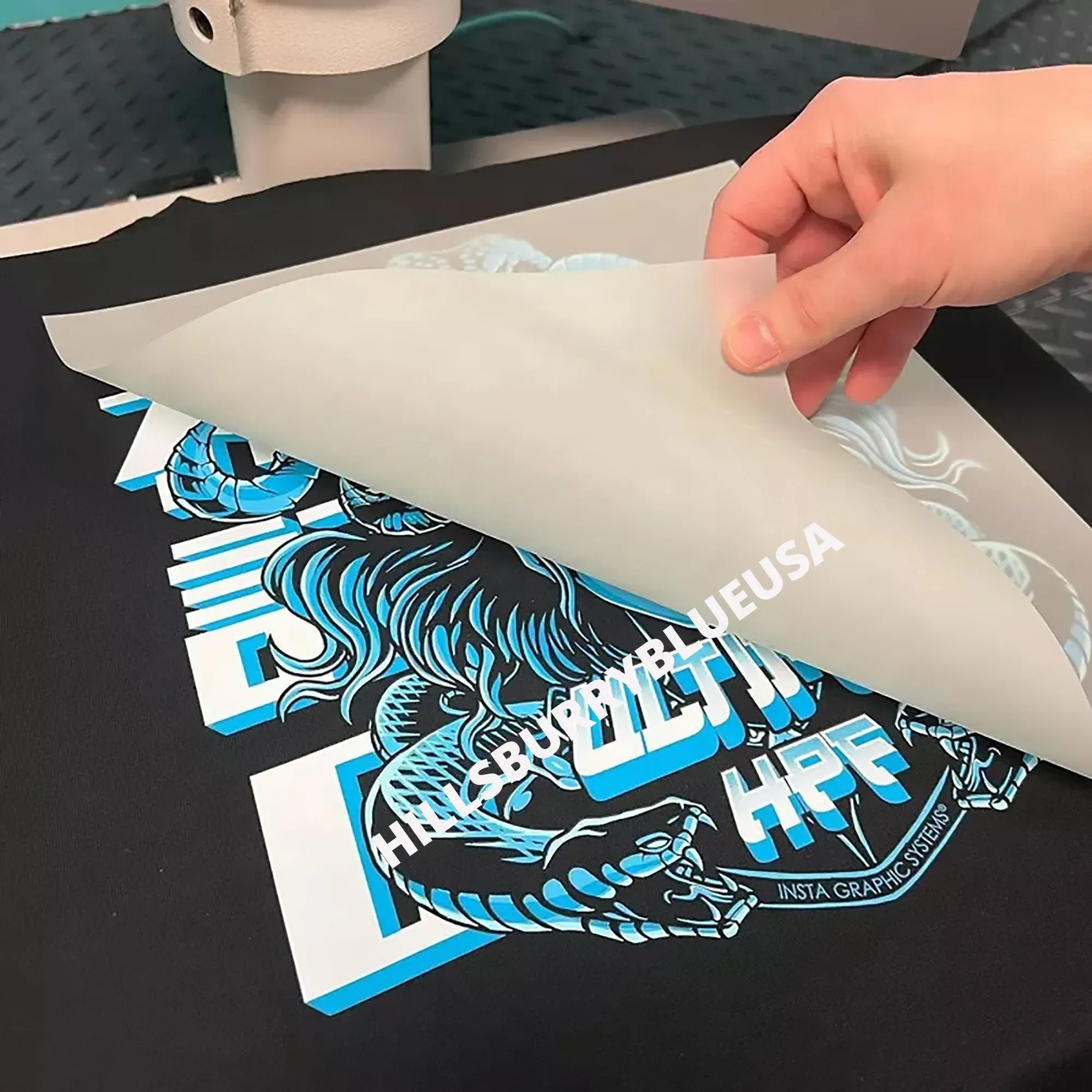

Implementing DTF transfers into your custom apparel production is straightforward, making it a highly appealing option for both novice and experienced printers. The process starts with pre-pressing the fabric to eliminate moisture, which is crucial for ensuring a smooth and effective transfer. Following this, the DTF transfer is carefully positioned on the desired area of the fabric to allow for accurate application of the design.

Once aligned, a heat press is used to apply consistent heat and pressure to the transfer, typically at around 320°F for 10-20 seconds. This step is vital, as it activates the adhesive and bonds the design to the fabric. After cooling, it’s essential to carefully peel off the PET film and, for added durability, re-press the fabric using parchment paper. This straightforward application process not only ensures high-quality results but also streamlines production, making it an ideal choice for businesses looking to maximize efficiency.

Innovative Advancements in DTF Printing Technology

The landscape of DTF printing technology is rapidly evolving, with continuous innovations that enhance its efficiency and output quality. Recent developments include the use of eco-friendly ink formulations, which not only contribute to a lower environmental impact but also provide richer colors and improved durability for prints. These advancements ensure that businesses can maintain high standards in their output while adhering to increasing consumer demand for sustainable practices.

Furthermore, the introduction of advanced DTF printers that integrate cutting-edge technology has made it easier than ever for printers to execute their ideas. Many of these printers come equipped with user-friendly interfaces and improved ink distribution systems, significantly reducing errors during the printing process. As the market continues to grow, embracing these innovative tools is crucial for any custom apparel business looking to stay competitive and ahead of the curve.

Comparing DTF Transfers with Other Printing Methods

When exploring options for custom apparel printing, it’s vital to understand how DTF transfers stack up against other common methods, such as direct-to-garment (DTG) and screen printing. One of the most prominent differences lies in fabric compatibility; DTF transfers can adhere to a wider variety of fabrics, while DTG typically performs best on cotton materials. This versatility opens up numerous creative avenues for those using the DTF process, enabling them to explore a broader array of products.

Moreover, when it comes to cost-effectiveness, DTF transfers stand out as an economical option due to their low startup costs and minimal equipment requirements. Unlike screen printing, which often necessitates significant initial investment for setup and materials, DTF does not demand pre-treatment of fabrics or extensive machinery, making it an attractive solution for small businesses and entrepreneurs seeking to enter the market without heavy financial burdens.

Market Outlook: Opportunities for DTF Printing

The market demand for DTF transfers is experiencing significant growth as businesses and consumers alike recognize the benefits of this innovative printing method. Companies such as We Print U Press and DTF Dallas are leading the charge by offering comprehensive solutions that cater to diverse printing needs. This increase in accessibility for both large and small businesses points to a vibrant future for DTF technology in the custom apparel sector.

For entrepreneurs looking to capitalize on this trend, the DTF transfer market presents a wealth of opportunities. As consumer preferences shift towards unique, high-quality designs, businesses that embrace DTF technology will be well-positioned to meet evolving demands. This printing method not only allows for exceptional quality prints but also provides the flexibility needed to adapt to the dynamic nature of fashion trends, marking DTF as a staple in the custom garment industry.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special polyester film using DTF inks. The process includes printing the design, applying adhesive powder, and heat curing the transfer onto the fabric. This method allows for vibrant, detailed images on various materials.

What are the advantages of using DTF printing technology for custom apparel?

DTF printing technology offers numerous benefits, including versatility on a wide range of fabrics, durability (lasting over 50 washes), and cost-effectiveness compared to methods like DTG printing. Additionally, it produces high-quality prints suitable for intricate designs.

Is DTF printing suitable for all types of fabrics?

Yes, DTF printing is ideal for various fabrics, including cotton, polyester, blends, leather, and nylon. This flexibility is one of the main reasons it’s gaining popularity in custom apparel printing.

How does DTF printing differ from direct-to-garment (DTG) printing?

DTF printing differs from DTG printing in several ways, including fabric compatibility, durability, and cost. While DTG works best on cotton fabrics, DTF can be applied to any fabric. DTF also has lower startup costs and does not require pre-treatment for fabrics.

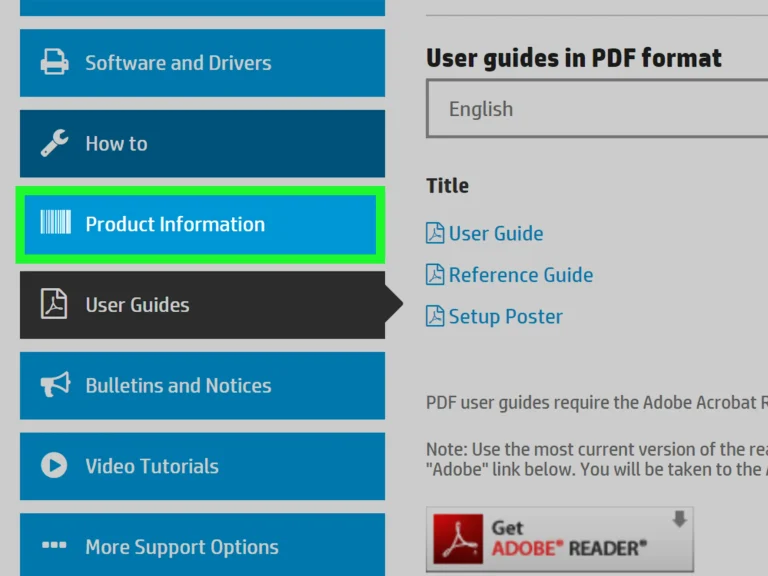

What equipment do I need to start DTF printing?

To begin with DTF printing, you’ll need a DTF printer for creating transfers, a heat press for application, adhesive powder to bond the design to fabric, and PET film for printing. This setup allows you to create high-quality DTF transfers effectively.

Are DTF transfers durable and how long do they last?

Yes, DTF transfers are highly durable and can withstand over 50 washes without fading or peeling. This makes them an excellent choice for sportswear and items that undergo frequent laundering, ensuring long-lasting quality.

| Feature | DTF Transfers | DTG | Screen Printing |

|---|---|---|---|

| Fabric Compatibility | Any fabric | Best on cotton | Best for simple designs |

| Durability | High | Medium | High |

| Full-Color Printing | Yes (unlimited colors) | Yes | Limited |

| Pre-Treatment Required | No | Yes | No |

| Startup Costs | Low | High | Medium |

| Application Ease | Simple | Moderate | Labor-intensive |

Summary

DTF Transfers are revolutionizing the custom printing landscape by combining quality with versatility. This innovative printing method facilitates the creation of durable, vibrant designs on a variety of fabrics without the need for costly equipment or pre-treatment. As the DTF process becomes more accessible, businesses and hobbyists alike can enjoy increased creative opportunities and efficiencies, making it an essential choice for custom apparel printing. With rising demand and continuous advancements in DTF technology, the method stands poised to dominate the future of garment printing.