DTF transfers have become a popular choice for garment decoration because they offer vibrant colorways, strong adhesion, and flexibility across a wide range of fabrics. To keep designs looking fresh from the first press to countless washes, you’ll want a solid understanding of best practices for this technique. This guide covers the essential steps, from design preparation to post-press care, so you can maximize the look, durability, and impact across fabrics and production scales. By following DTF printing techniques, you can manage color accuracy and adhesion across fabrics, while staying mindful of substrate differences, curing times, and post-press care. Attention to heat pressing for DTF transfers helps ensure consistent results and improved DTF transfer durability over time, reducing the risk of cracking, fading, or peeling with normal wear.

Latent Semantic Indexing principles align these concepts with alternative terms such as direct-to-film decoration and print-on-film transfers, both referring to a film-based method that carries artwork to textiles. Think of a printable film with an adhesive layer that binds to fabric when heat is applied, enabling bold designs on cotton, blends, and performance fabrics. From an SEO and reader perspective, you can frame this technique with related terms like film-based transfer, adhesive-coated film, and digital textile decoration to connect topics such as design preparation, material selection, and press settings. Together, these terms help ensure your description remains accessible while signaling to search engines the broader scope of garment decoration technology.

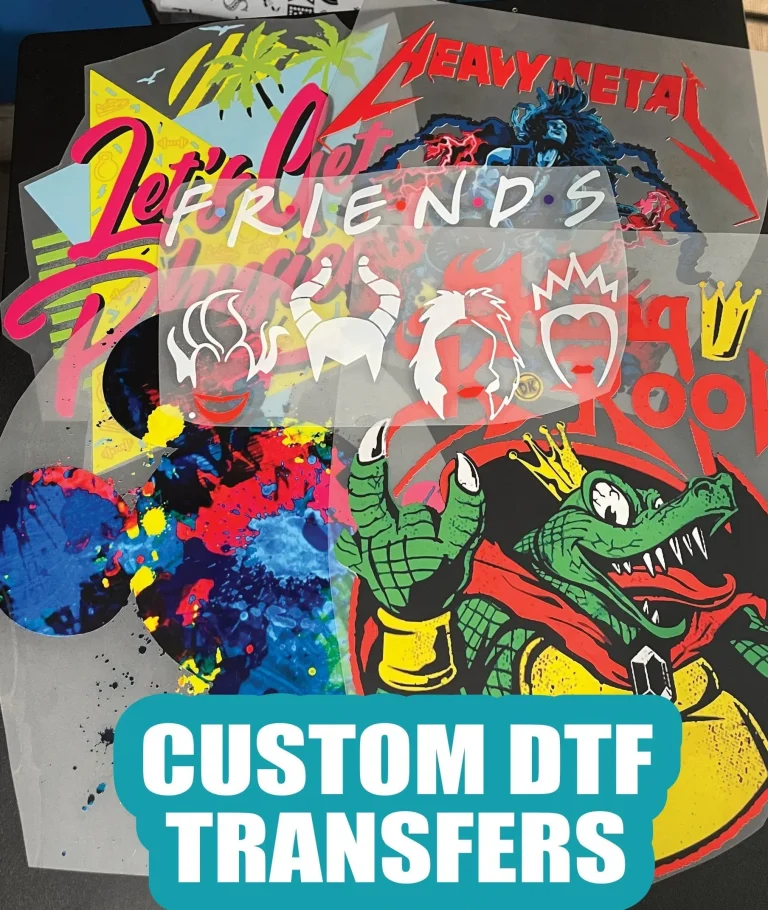

DTF transfers: Maximizing durability with optimized heat pressing and printing techniques

DTF printing techniques revolve around precise color management, film quality, and careful powder application to ensure durable results. By pairing these techniques with heat pressing best practices for DTF transfers—such as appropriate temperature, pressure, and dwell time—you can significantly improve adhesion and longevity across a variety of fabrics. A solid workflow includes pre-pressing to remove moisture, precise alignment, and controlled heat and pressure to embed the design without compromising texture or flexibility.

In practice, maintaining DTF transfer durability means treating every step like a repeatable process. This includes using a white underbase strategically on dark fabrics, documenting press settings, and performing post-press curing when needed to maximize bond strength. Regular maintenance of the heat press and awareness of fabric type help prevent common issues like cracking, peeling, or color fading after multiple washes, ensuring that your vibrant designs stay consistent over time.

DTF design optimization tips for maintaining vibrant designs across fabrics

DTF design optimization tips start with meticulous design prep. Prepare artwork at high resolution (300 dpi or higher) and consider vector files for scalable prints. Color management and proofing, along with a test strip, help ensure the final print aligns with your expectations on different fabrics. This aligns with principles of DTF printing techniques and supports consistent color reproduction across batches while safeguarding vibrancy.

Beyond file prep, the strategy for layering, color separations, and opacity is crucial. Plan white underbase placement, manage color layers, and design with practical print limits to avoid over-drying or bleeding. Emphasize contrast and legibility on fabric, scale placements for various garment sizes, and maintain a documented style guide to preserve the intended look. These practices help maintain vibrant DTF designs and support long-term visual impact across multiple wears and washes.

Frequently Asked Questions

How do DTF printing techniques influence maintaining vibrant DTF designs and their transfer durability over time?

DTF printing techniques affect color accuracy, opacity, adhesion, and wash durability. For best results, design at high resolution (300 dpi or higher) with color-managed workflows, include a dedicated white underbase when printing on dark fabrics, and keep color layers clearly organized. Use high-quality transfer film and consistent inks, ensure even powder distribution, and run a test print on the target fabric to verify vibrancy and adhesion before full production.

What are the best practices for heat pressing for DTF transfers to maximize durability and color retention, guided by DTF design optimization tips?

Use a repeatable heat-press workflow: pre-press to remove moisture, then align the transfer; press at about 300–320°F (150–160°C) with firm pressure for 12–20 seconds, and let the print cool before peeling. If needed, perform a cure step and use a protective sheet as your film requires. Apply DTF design optimization tips to plan color separations, sequencing, opacity, contrast, scale, and placement to preserve sharp edges and legibility across washes.

| Aspect | Key Points | Benefits / Impact | Best Practices |

|---|---|---|---|

| What are DTF transfers? |

|

|

|

| Design preparation |

|

|

|

| Materials & equipment |

|

|

|

| The transfer process: from design to finished print |

|

|

|

| Maintaining color freshness and durability |

|

|

|

| Troubleshooting common issues |

|

|

|

| Design optimization tips to keep designs fresh |

|

|

|

Summary

DTF transfers offer a compelling blend of design flexibility, vibrant color reproduction, and durable performance across a wide range of fabrics. By following best practices—from design preparation to proper pressing and post-press care—you can maximize look, durability, and color accuracy across garments. Embrace careful material selection, repeatable processes, and ongoing testing to keep DTF transfers looking fresh and impactful for customers.