DTF Transfers, or Direct-to-Film transfers, have revolutionized the printing landscape, presenting an innovative way to create stunning, vibrant prints on various fabrics. This advanced technique allows designers and businesses to produce high-quality graphics that truly stand out, giving them a competitive edge in the custom apparel market. By understanding the DTF transfer process, including how to use DTF transfers effectively, you can enhance your designs and engage customers with visually striking products. With the right heat press DTF transfers method and some valuable DTF printing tips, you can achieve professional results that are both durable and visually unique. Dive into the art of DTF printing and discover how to bring your designs to life with exceptional color vibrancy and detail.

The realm of textile printing is continually evolving, and one of the standout methods currently dominating the industry is Direct-to-Film printing. This approach, which is often referred to by its initials, DTF, simplifies the transfer of intricate designs onto fabric, making it an ideal choice for those looking to elevate their garment design game. Whether it’s through the use of vibrant graphics or the latest heat transfer techniques, mastering the DTF transfer method can significantly enhance the quality and appeal of your finished products. Furthermore, a detailed examination of how to effectively implement this process can lead to improved results and greater satisfaction for both creators and consumers. Exploring DTF printing not only opens doors to creativity but also equips artists and entrepreneurs with the tools needed to succeed in a competitive market.

Exploring the DTF Transfer Process

The DTF transfer process begins with printing your design onto a special film using high-quality inks. This step is critical as it establishes the color saturation and detail that are vital for vibrant DTF prints. Once printed, the film is coated with a special powder adhesive, which is then cured using heat. This procedure ensures that the ink adheres firmly to the film, creating a reliable transfer that can be placed onto fabric later. The meticulous combination of heat, pressure, and time during the transfer process will ultimately define the quality of the final print.

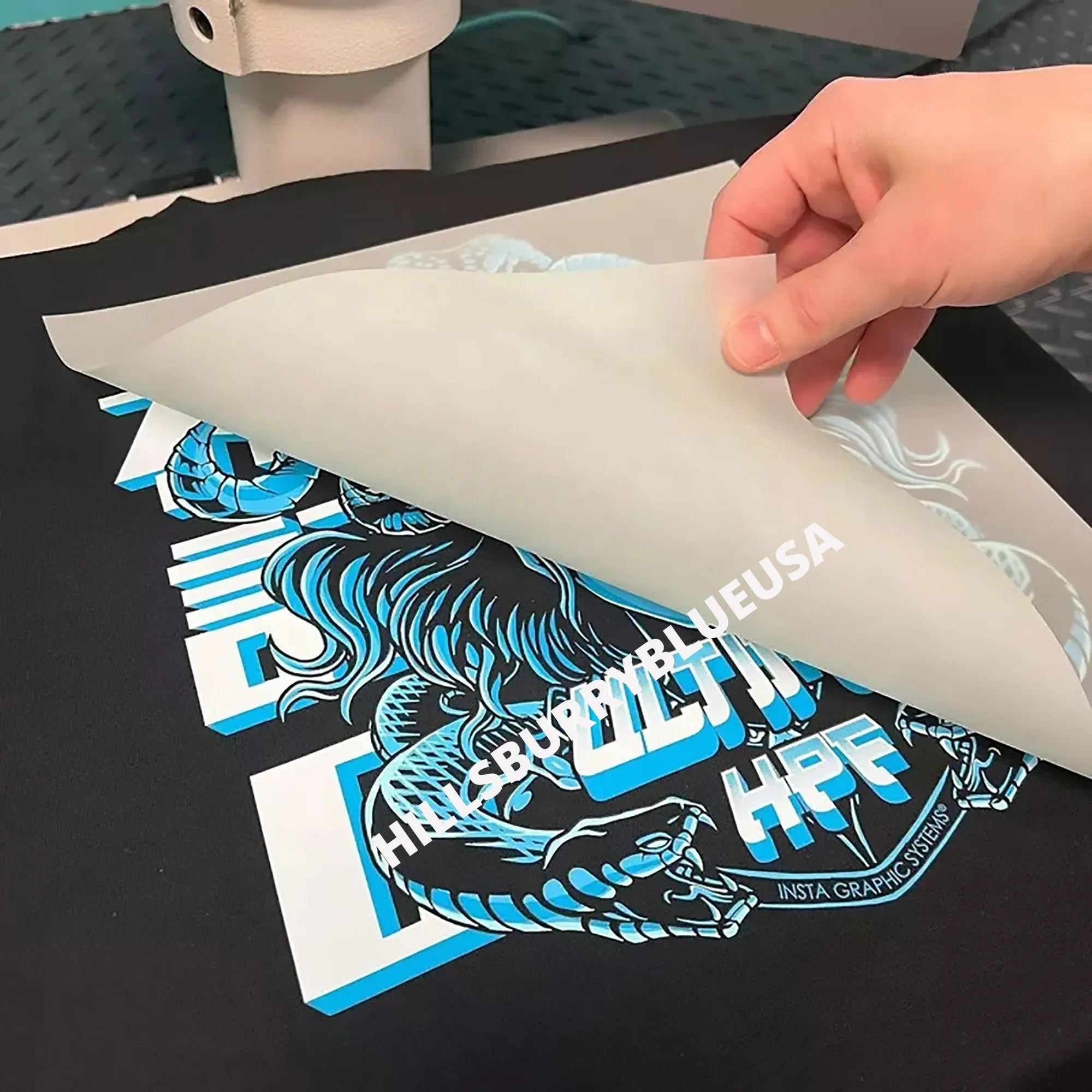

After the film has been prepared, the next phase is to use a heat press to transfer the design onto your chosen fabric. The temperature typically hovers around 320°F, applied with firm pressure for about 10-15 seconds. This crucial step not only ensures the adhesive properly bonds with the textile but also activates the ink on the film. The level of detail and the vibrancy of colors achieved through this process can significantly impact the overall appearance of the final product. Therefore, understanding each facet of the DTF transfer process is imperative for achieving exceptional results.

Benefits of Using DTF Transfers

One of the primary advantages of DTF transfers is their remarkable color vibrancy. Unlike traditional printing methods, DTF transfers allow intricate designs to showcase a broader color gamut, making prints appear more dynamic. The combination of high-quality inks and innovative transfer techniques enables designers to bring their visions to life effectively. Additionally, the versatility of DTF transfers allows for application across various fabric types, including cotton, polyester, blends, and even specialty textiles, providing creatives endless possibilities for customization.

Durability is another stand-out feature of DTF transfers. When properly executed, these prints can withstand multiple washes without fading or cracking, maintaining their vibrant appearance over time. This longevity is particularly beneficial for businesses seeking to produce quality apparel that can endure the rigors of everyday use, making them ideal for both promotional items and retail products. The ability to create long-lasting, high-end prints helps brands establish a strong reputation for quality in a competitive marketplace.

Mastering Heat Press Techniques for DTF Transfers

Mastering the heat press technique is essential in achieving optimal results with DTF transfers. Achieving the right temperature and pressure settings is crucial; typically, a temperature of around 320°F with firm pressure for 10-15 seconds is recommended. Adjustments might be necessary depending on the fabric type, as some textiles may require a slightly different approach. Additionally, whether to follow a hot or cold peel method can impact the look of the print, so it’s vital to test both options to find which works best for your specific materials and designs.

Furthermore, ensuring proper curing post-transfer enhances the vibrancy and cohesion of DTF prints. Allowing prints to cure effectively will not only solidify the adhesive bond but will also improve the fade resistance of the colors over time. Regular maintenance and calibration of the heat press will guarantee consistent results, which is critical for those engaging in high-volume production. By continuously perfecting your heat press technique, you enhance the overall quality of each print, ensuring customer satisfaction with every order.

Essential Tips for Vibrant DTF Prints

Achieving vibrant DTF prints requires a commitment to quality at every stage. One vital tip is to always conduct test prints before starting a larger batch. This practice allows you to assess color quality and ensure alignment is perfect. Utilizing quality materials—like premium inks and film specifically designed for DTF printing—will also contribute to the vibrancy of the final product. A keen understanding of different fabric types and experimenting with various transfer papers can lead to improved results, so don’t hesitate to explore these options.

In addition to testing and material selection, maintaining an organized workspace can significantly impact your printing outcomes. Keeping your printing equipment clean and ensuring that everything is properly calibrated eliminates many common issues such as ink clogging or misalignment. Additionally, staying informed about the latest innovations in DTF printing technology can provide new insights and techniques that enhance your printing process. With these tips, you will be well on your way to mastering vibrant DTF prints that capture attention.

Common Mistakes to Avoid in DTF Printing

Identifying and avoiding common mistakes in DTF printing can save time and resources while improving quality. One prevalent issue is using low-quality inks or films, which can lead to lackluster prints and quick fading. It’s essential to invest in high-grade supplies that have been specifically developed for DTF applications. Neglecting to optimize printer settings according to the type of fabric used is another common mistake that can drastically affect color output and detail.

Finally, neglecting regular maintenance of your printing equipment can lead to performance issues over time. It’s essential to form a routine that includes cleaning the printer and heat press to avoid any debris buildup that can impact print quality. Make it a habit to track your equipment’s performance through a maintenance log, which will help you spot potential issues before they affect your output. By steering clear of these common pitfalls, you can enhance the efficiency and quality of your DTF printing projects.

Innovations in DTF Printing Technology

The DTF printing industry has witnessed remarkable innovations in recent years, contributing to enhanced color vibrancy and efficiency. Updates in ink formulations and film technology have allowed for brighter colors that maintain their intensity even after multiple washes. Companies like Insta Graphic Systems are at the forefront of offering products that maximize color output and durability, revolutionizing how prints are created. Being informed about these advancements can significantly impact your production capabilities and the quality of the finished product.

Additionally, the emergence of user-friendly software enables designers to streamline the DTF printing process. This software often includes features that facilitate better designs and edits while automating much of the setup required in traditional settings. Integrating technology into your DTF printing process can enhance productivity and reduce the margin for error, ensuring that every print meets the high standards expected in today’s market. Keeping an eye on these innovations will position you advantageously within the competitive landscape of custom apparel.

Frequently Asked Questions

How do I use DTF transfers effectively?

To use DTF transfers effectively, start by printing your design on a special DTF film using high-quality inks. Ensure your printer settings are optimized for vibrant colors and high resolution. Once printed, apply the film onto your chosen fabric using a heat press at approximately 320°F for 10-15 seconds, maintaining firm pressure. Following the heat application, the transfer can be peeled off depending on whether you’re using a cool or hot peel method.

What are some tips for achieving vibrant DTF prints?

For achieving vibrant DTF prints, use high-quality DTF printing materials, including specialized inks and films. Adjust your printer settings for higher saturation and resolution. Always conduct test prints to check color accuracy. After transferring, allow prints to cure to enhance vibrancy and longevity. Regular maintenance of your printing equipment also plays a role in ensuring consistent print quality.

What does the DTF transfer process involve?

The DTF transfer process involves several key steps: first, print your design onto a DTF film. Next, apply adhesive powder to the wet ink and cure it. Then, use a heat press to transfer the design onto fabric. It’s essential to ensure the correct temperature and pressure settings during the heat pressing to achieve detailed and vibrant prints.

What are the benefits of using heat press DTF transfers?

Heat press DTF transfers offer several benefits including exceptional color vibrancy and detail, the ability to print on various fabric types, and durability that withstands washing. This method allows for intricate designs while ensuring that colors remain bright over time, making it an ideal choice for custom apparel.

What are common DTF printing tips for beginners?

Beginner DTF printing tips include investing in quality inks and films, optimizing printer settings for better saturation, and practicing with different fabric types. Start by creating test prints to fine-tune your process and ensure your equipment is well-maintained to avoid printing defects. Additionally, staying updated with DTF printing innovations can enhance your results.

Can I use DTF transfers on all fabric types?

Yes, DTF transfers are versatile and can be applied to a wide range of fabric types, including cotton, polyester, and blends. This makes DTF printing suitable for various projects, ensuring you can achieve vibrant and durable designs across different merchandise.

| Key Point | Details |

|---|---|

| Understanding DTF Transfers | DTF transfers involve printing designs on a film that is later transferred to fabric using heat, ensuring bright colors and intricate designs. |

| Why Choose DTF Transfers? | 1. Vibrant Colors 2. Versatile Fabric Compatibility 3. Durable Prints |

| Key Steps to Achieve Vibrant Prints | 1. Quality Materials 2. Optimize Printer Settings 3. Mastering Heat Press Technique 4. Experiment with Transfer Papers 5. Regular Equipment Maintenance |

| Tips for Enhanced Results | – Allow Prints to Cure – Conduct Test Prints – Stay Updated with Innovations |

Summary

DTF Transfers are a revolutionary method in the printing industry that offers vibrant, high-quality prints for custom apparel and textile designs. This technique utilizes advanced technology to effectively transfer detailed designs onto various fabric types with outstanding color output. By focusing on using quality materials, optimizing printer settings, mastering heat press techniques, and regularly maintaining equipment, creators can achieve exceptional results that stand out in a competitive market. Emphasizing innovation and experimentation in this dynamic field will ensure continued success and longevity of your DTF printing endeavors.