DTF transfers, or Direct-to-Film transfers, are transforming the landscape of personalized apparel and promotional items. This innovative printing technique has surged in popularity due to its flexibility and cost-efficiency, accommodating a plethora of fabric types. In this guide, we delve into the essential techniques to perfect DTF transfers, from selecting the best DTF transfer suppliers to exploring the latest DTF printing innovations. With the ability to reproduce vibrant colors and intricate details, mastering DTF printing techniques can significantly elevate your design projects. Join us as we explore step-by-step methods to enhance your DTF transfer process and achieve professional-quality results.

Direct-to-Film transfer techniques, often referred to in the industry as DTF printing methods, represent a cutting-edge approach to garment decoration and personalization. This process involves the precise transfer of artistic designs using a specialized film that adheres seamlessly to various fabric surfaces. The versatility of DTF applications means it’s ideal for a wide range of products, from t-shirts to promotional goods. As digital printing continues to innovate, mastering these printing methods and sourcing top-quality transfer materials is essential for achieving exceptional custom designs. Whether you are a business owner or a hobbyist, understanding these concepts is crucial for standing out in the crowded market of personalized items.

Mastering DTF Printing Techniques for Optimal Results

Mastering DTF printing techniques is essential for achieving optimal results in your projects. The printing process begins with proper preparation, including selecting the right printer and ensuring you have high-quality DTF ink that complements the material you’re working with. Utilizing an inkjet printer that is specifically designed for DTF printing can make a significant difference in the vibrancy and durability of your designs. For best outcomes, it’s imperative to fine-tune your printer settings, opting for the highest resolution to capture intricate details and colors accurately.

In addition to printer selection, understanding the nuances of DTF inks plays a crucial role in the final product. Each ink type may behave differently based on the fabric composition and transfer film being used. Experimenting with various color profiles in a controlled environment can lead to breakthroughs in color fidelity, allowing you to achieve sharper and more vibrant prints. Staying updated on the latest advances in ink formulations can open new avenues in DTF printing, ensuring your designs are not only appealing but also long-lasting.

Choosing the Best DTF Transfer Suppliers

Finding the best DTF transfer suppliers is crucial for anyone venturing into the world of DTF printing. High-quality materials can significantly affect the adherence and longevity of your designs. Reputable suppliers often provide detailed specifications about their transfer films and the inks they use, allowing crafters to make informed decisions. When scouting for the best suppliers, consider their market reputation, customer reviews, and the diversity of their product offerings. Brands like Eazydtf are pioneering quality enhancements, which crafters should absolutely consider for fulfilling various project requirements.

Moreover, connecting with suppliers who excel in customer service can also enhance your DTF experience. They can offer assistance with product selection, share printing tips, and troubleshoot issues you may encounter during the process. By fostering a relationship with dependable suppliers, you create a support system that can lead to more successful projects. This connection is particularly valuable for transitioning from trial-and-error methods to a more streamlined production process in your crafting ventures.

The Importance of Heat Application in DTF Transfers

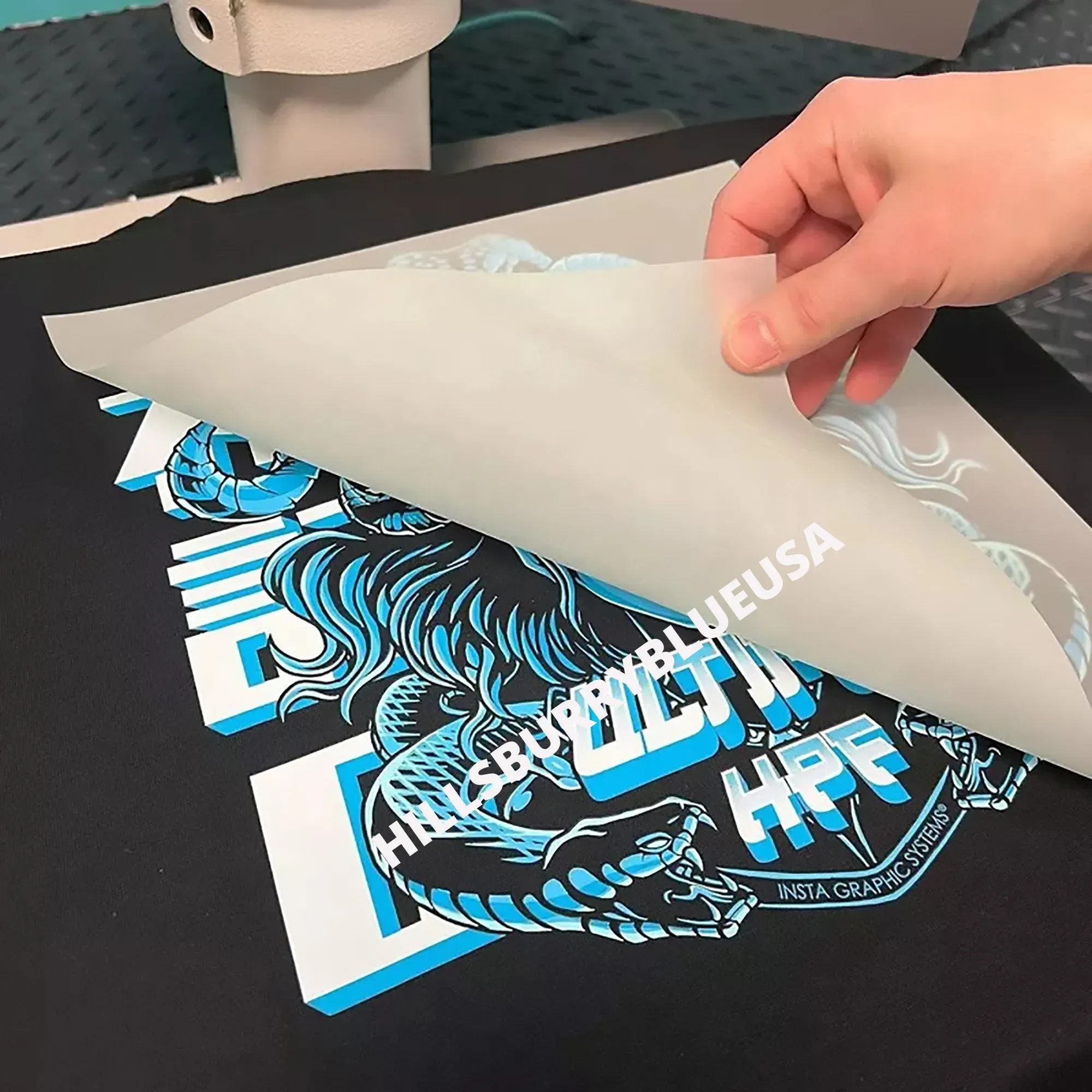

Heat application is a critical component that can make or break your DTF transfer attempts. The key to a successful application lies in adhering to the recommended temperature and pressure settings specific to each transfer you’re applying. Generally, a range of 320°F to 350°F (160°C to 180°C) is suggested, but every material may require its own adjustments. Ensuring precision here can significantly affect how well your transfer adheres, and affects the overall appearance of your finished product.

Failure to apply the correct pressure during the transfer can lead to disastrous results, from peeling to crispy edges that mar the design. Understanding your heat press capabilities and nuances can provide better control over the output. Additionally, knowing the right timeframe, typically around 10-15 seconds, can ensure that the transfer adheres without damaging the print. Mastery of heat application techniques enhances the robustness of your DTF transfer projects, securing longevity and maintaining a professional look.

Exploring Recent Innovations in DTF Printing

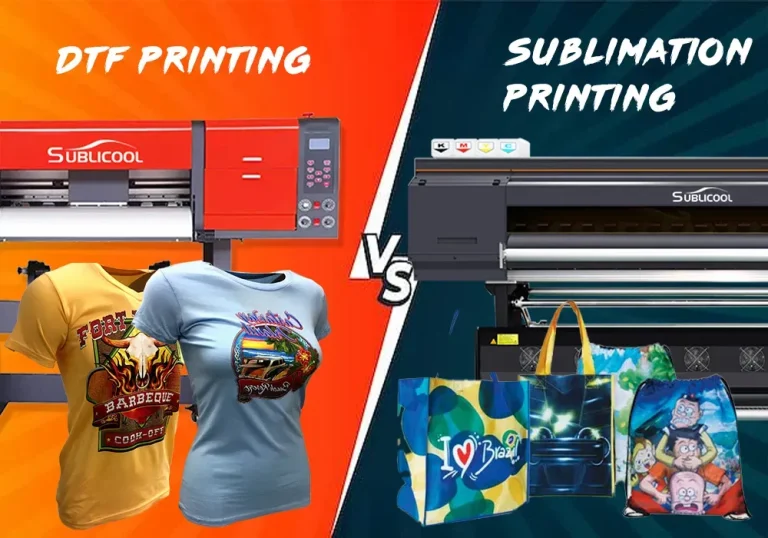

Recent innovations in DTF printing technology are reshaping the landscape of custom design capabilities. The introduction of hybrid printers, like the Sawgrass VersiFlex, combines the features of dye-sublimation, Direct-to-Garment (DTG), and DTF technologies, facilitating seamless transitions between various materials. This convergence allows for greater flexibility in design, enabling crafters to diversify their offerings and expand their creative horizons. Staying informed about such advancements is crucial for anyone looking to elevate their projects and stay competitive in the market.

Additionally, these innovations often bring about enhancements in efficiency. Newer models are generally faster, allowing for quicker production times which are essential in a market that demands rapid turnaround. Implementing these cutting-edge tools not only boosts your productivity but also improves the quality and precision of your final products. By embracing the latest innovations in DTF printing, you can position yourself at the forefront of customization technology, resulting in exceptional projects that stand out in the crowded marketplace.

Identifying Market Trends in DTF Printing

Understanding market trends in DTF printing can provide vital insights for both new and seasoned crafters. Currently, there is a significant increase in demand for personalized and custom-designed products, with small business owners and hobbyists leading the charge. The DTF method offers an economical yet high-quality solution that aligns perfectly with these market trends, making it an attractive option for those looking to enter or expand within the customization space.

Furthermore, advancements in DTF printing technologies encourage faster production methods, giving crafters an edge in fulfilling orders quickly. As consumers increasingly seek unique and personalized items, staying attuned to these trends cultivates opportunities to cater to this growing niche. By adapting your skills and practices to meet evolving demands, you can enhance your position in the marketplace and secure a robust customer base for your DTF transfer creations.

Step-by-Step Guide to Perfecting Your DTF Transfers

Perfecting your DTF transfers involves a well-structured approach, starting from choosing the right materials to mastering the printing and application methods. Following a step-by-step guide allows you to break down the process into manageable segments, ensuring that no detail is overlooked. Begin with thorough research on the best DTF transfer suppliers and familiarize yourself with the varieties they offer, which will set the stage for a successful printing experience.

Once you have a firm grasp on your materials, the next steps include printing techniques, heat application, and finishing touches. Each phase requires attention to detail and a commitment to quality, which results in vibrant and durable designs. By implementing a systematic approach, embracing the latest innovations, and continuously refining your techniques, you can achieve stunning results with your DTF projects that truly reflect your creative vision.

Frequently Asked Questions

What are the best DTF transfer suppliers for high-quality materials?

Choosing the best DTF transfer suppliers is crucial for achieving excellent results. Look for reputable vendors such as Eazydtf, which specializes in high-quality DTF films and inks. Suppliers that provide detailed specifications about their products will help ensure better adhesion and vibrant prints.

How to perfect DTF transfers using heat application?

To perfect DTF transfers, proper heat application is essential. Set your heat press to around 320°F to 350°F and use adequate pressure for 10-15 seconds. This ensures the transfer adheres correctly to the fabric, resulting in a durable design.

What DTF printing techniques can enhance my designs?

Utilizing the right DTF printing techniques is key to enhancing your designs. Ensure your printer is compatible with DTF inks, set the resolution to the highest setting, and use high-quality inks for vibrant color reproduction. This will yield clearer and more defined prints.

What recent innovations are shaping the future of DTF transfers?

Recent innovations in DTF transfers, such as the Sawgrass VersiFlex technology, combine dye sublimation and DTF methods, allowing for versatile applications on various materials. Staying updated with these advancements can significantly improve production quality and design capabilities.

How do DTF printing innovations affect the customization market?

DTF printing innovations are positively impacting the customization market by providing more efficient production techniques and higher quality outputs. With advancements in equipment, crafters can now deliver personalized items quickly and affordably, driving demand for DTF transfers.

What are the common issues faced when using DTF printing techniques?

Common issues with DTF printing techniques include poor adhesion, peeling, and fading. To avoid these problems, it is crucial to select high-quality DTF transfers, set the correct heat and pressure, and ensure printer compatibility with DTF inks.

| Key Steps | Details |

|---|---|

| Step 1: Choosing the Right DTF Transfers | Select high-quality transfers from reputable suppliers for better adhesion and detail. |

| Step 2: Printing Techniques | Use an inkjet printer designed for DTF, ensuring compatibility and high-resolution settings. |

| Step 3: Heat Application | Apply heat between 320°F to 350°F with adequate pressure for 10-15 seconds. |

| Step 4: Recent Innovations and Tools | Utilize advancements like the Sawgrass VersiFlex for enhanced printing versatility. |

Summary

DTF transfers are transforming the way individuals and businesses approach custom printing. By meticulously selecting high-quality materials, employing effective printing techniques, and applying the right heat settings, users can create visually striking and durable designs. The DTF printing process stands out due to its ability to reproduce intricate details and vibrant colors on various fabrics, making it a popular choice among crafters looking for versatility and quality. As technology continues to evolve, staying updated on the latest innovations further enhances the DTF experience, ensuring that your creative projects can achieve the best possible outcomes.