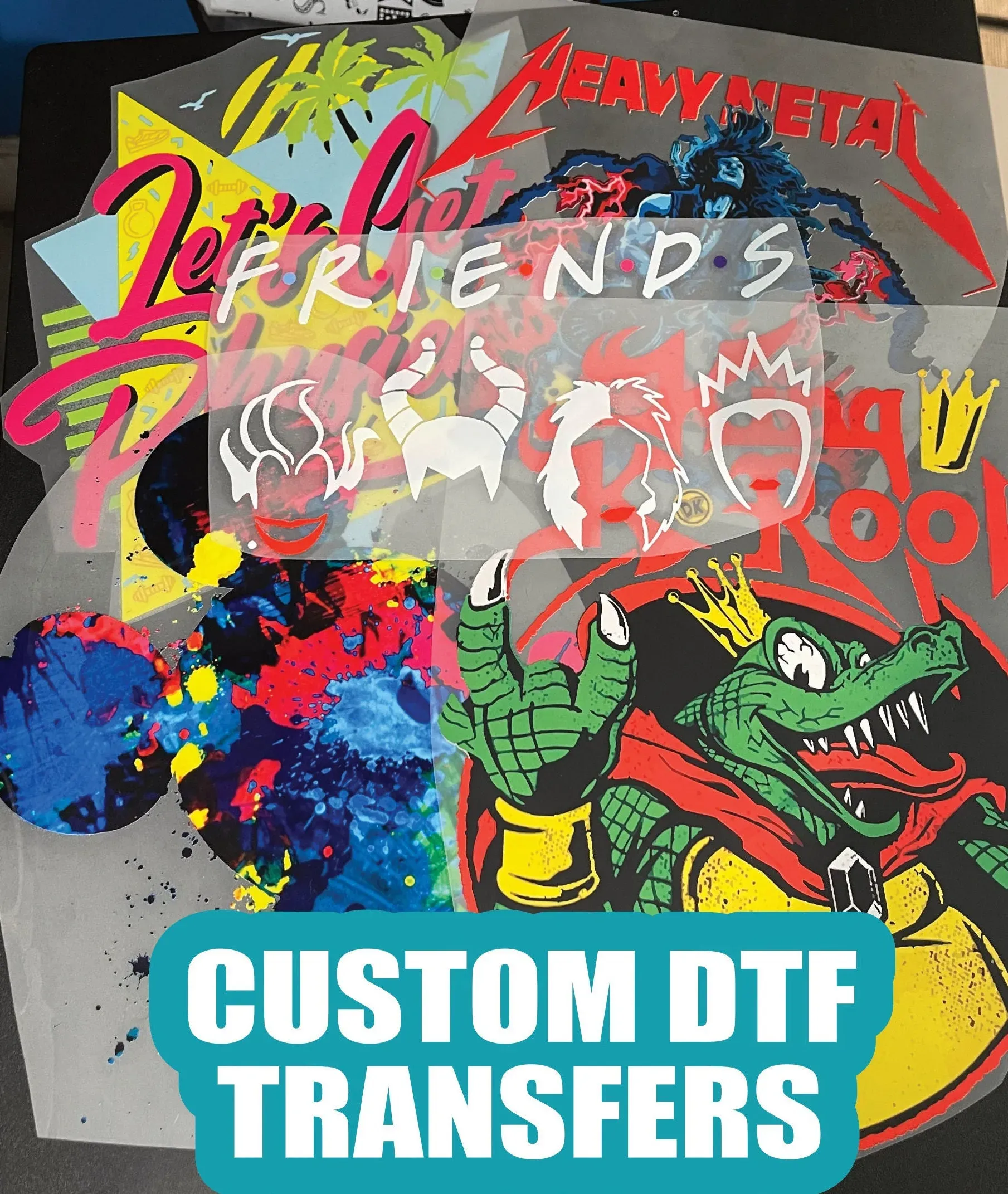

DTF transfers, or Direct-to-Film transfers, represent a cutting-edge printing technique that has rapidly gained traction in the textile industry. This method is celebrated for its ability to produce vivid colors and intricate designs that can adorn a variety of fabrics effortlessly. However, mastering the art of DTF transfers involves more than just having the right equipment; it requires careful attention to detail and a solid understanding of best practices. In this article, we will delve into 10 essential tips that ensure your DTF transfers achieve the highest quality possible, from selecting quality DTF films to fine-tuning heat press settings. By employing these strategies, you can elevate your DTF printing efforts and create stunning, durable designs that will captivate your audience.

Direct-to-Film printing, often referred to as DTF, is revolutionizing the way custom designs are applied to fabric surfaces. This innovative approach allows for the creation of vibrant and stunning graphics that stand out in a crowded marketplace. Whether you are a small business owner or a passionate hobbyist, understanding DTF transfers is essential for achieving professional results. With the right techniques and equipment, including consideration of heat application and film quality, you can dramatically increase the functionality and visual appeal of your printed items. Let’s explore effective methods to perfect your transfer process and ensure your prints not only look fantastic but are also built to last.

Understanding DTF Printing Basics

Direct-to-Film (DTF) printing is a revolutionary method in the world of fabric printing that allows for an incredibly vibrant and detailed print outcome. Unlike traditional screen printing methods, DTF printing creates a transfer film that can then be applied to various types of fabrics, providing the flexibility that many printing businesses thrive on. As this method continues to gain traction, understanding the core principles and techniques involved is essential for anyone looking to excel in this field.

This innovative process requires a solid understanding of several components, including film quality, ink selection, and heat application. By mastering these elements, one can ensure that prints are not only colorful but also durable and long-lasting. As you delve deeper into DTF printing, you’ll recognize the importance of precision in every step, from printing to heat pressing.

Tips for Choosing Quality DTF Films

When it comes to DTF printing, the choice of transfer films can significantly impact the final print quality. Selecting the right films means looking for those that are designed specifically for DTF applications, as these have features like optimized coating for better ink adhesion and enhanced durability in wash cycles. Investing in high-quality films is not merely a choice; it’s a necessity to deliver eye-catching designs that withstand the test of time.

Moreover, reputable brands are typically backed by testimonials from the DTF printing community, indicating their reliability in producing consistent results. In addition, consider factors such as the type of fabrics you will be transferring onto and the environmental conditions that might affect the prints, ensuring your choice complements your printing needs.

DTF Transfer Tips for Optimal Results

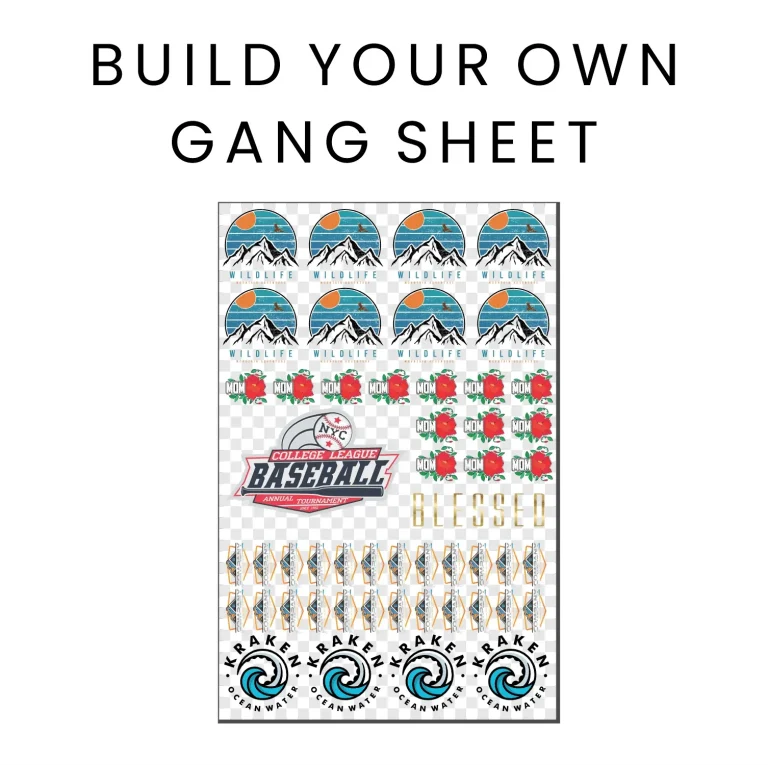

To optimize the results of your DTF transfers, understanding the application process is key. Start by ensuring that your application surface is prepped correctly; this includes pre-pressing garments to remove excess moisture and wrinkles. Moreover, applying the correct amount of adhesive powder after printing is crucial for preventing peeling and enhancing longevity. Employing a powder applicator can help achieve an even distribution, which is fundamental for achieving high-quality outcomes.

Testing various combinations of adhesive and compatibility with different fabrics can also help fine-tune your process further. Take your time to get familiar with the intricacies of applying DTF transfers, and the payoffs will be evident in the quality of your finished products.

Essential Heat Press Settings for DTF Transfers

The heat press settings you employ are vital in determining the success of your DTF transfers. Generally, it’s recommended to maintain a temperature around 320°F (160°C) with medium pressure for about 15 seconds. Nevertheless, variations may be required based on the fabric type and the adhesive used, so conducting tests is essential to align your settings for optimal results. One should frequently check equipment accuracy to ensure a consistent application across different batches.

Additionally, if you are working with multiple fabric types, keeping a record of the unique settings that yield the best results for each material can save time and resources in future projects. Fine-tuning your heat press parameters can be the difference between an effective transfer and a ruined print, so make it a priority to master these settings.

The Importance of Ink Selection in DTF Printing

In DTF printing, the selection of inks is critically important as they influence not only the vibrancy of your prints but also the durability and washability of the designs. It’s advisable to use inks specifically formulated for DTF printing, as these have the right viscosity and adhesion properties needed to bond with the film and fabric. High-quality inks enhance the overall aesthetic of your transfers, ensuring they stand out and meet customer expectations.

Moreover, keeping abreast of new ink products and formulas on the market allows you to experiment and discover inks that yield even better results. Engaging with fellow DTF enthusiasts can provide insights into successful ink combinations, ultimately refining your printing process and elevating your output.

Maintaining and Cleaning Your DTF Equipment

Regular maintenance and cleaning of both your printer and heat press are essential parts of the DTF printing process. Dust and ink residue can accumulate over time, possibly leading to inconsistent print quality, clogging, and other complications. Establishing a cleaning schedule will help prolong the life of your equipment and ensure that your prints maintain their high quality across all productions.

Take specific care with cleaning methods recommended by manufacturers, as improper cleaning can damage your equipment. Regularly inspect parts of the apparatus that require maintenance and stay organized in documenting any changes to equipment settings after cleaning, as this ensures optimal functionality and output quality. Consistent upkeep goes a long way in minimizing unforeseen printing issues.

Frequently Asked Questions

What are the key benefits of using DTF transfers for printing designs?

DTF transfers, or Direct-to-Film printing, offer several advantages including vibrant colors, intricate designs, and the ability to print on a wide variety of fabrics. These transfers provide excellent adhesion and durability, making them a popular choice for professional and DIY printing projects.

How can I choose the best DTF films for my transfers?

To ensure high-quality DTF transfers, opt for films from reputable brands that are known for their performance in DTF printing. Quality DTF films enhance ink adhesion, produce striking colors, and improve overall image clarity, which can prevent issues like peeling or cracking.

What are the ideal heat press settings for DTF transfers?

For successful DTF transfers, it’s recommended to set your heat press to approximately 320°F (160°C) with moderate, even pressure. These settings may vary depending on the type of fabric used, so performing test presses is crucial to achieve the best results.

What type of inks should I use for DTF printing?

Choosing high-quality DTF inks that are compatible with your printer is essential for achieving vibrant and durable transfers. Look for specifically formulated inks designed for DTF printing to enhance the quality of your designs and ensure longevity.

How can I ensure proper adhesion when using DTF transfers?

To achieve proper adhesion with DTF transfers, it’s important to pre-press the garment to remove moisture and wrinkles, apply adhesive powder evenly, and allow the transfer to cool before peeling it off. These steps help enhance the bond and durability of the transfer.

What should I do to maintain my DTF printing equipment?

Regular maintenance of your DTF printing equipment is essential for optimal performance. Clean your printer and heat press regularly to prevent ink clogging and ensure consistent pressure during transfers, thereby improving overall print quality.

| Tip Number | Key Point |

|---|---|

| 1 | Choose high-quality transfer films for better adhesion and vibration of colors. |

| 2 | Ensure optimal printer settings for DTF printing to achieve accurate color reproduction. |

| 3 | Use high-quality DTF inks for vibrant designs and durability. |

| 4 | Accurate heat press settings are critical for successful transfers. |

| 5 | Pre-pressing garments is necessary to remove moisture and wrinkles. |

| 6 | Apply adhesive powder evenly after printing for consistent results. |

| 7 | Cure the transfers properly by allowing them to cool before peeling. |

| 8 | Always conduct test prints to identify potential issues. |

| 9 | Regularly clean your printer and heat press equipment. |

| 10 | Stay informed through community forums and resources. |

Summary

DTF Transfers have revolutionized the way we approach fabric printing, offering vibrant colors and intricate designs that appeal to a wide audience. By mastering key techniques such as selecting the right films, optimizing printer settings, and ensuring proper heat application, you can achieve outstanding results that not only impress your customers but also elevate your artistry in garment printing. Regular engagement with the DTF community and continual learning will keep you updated on best practices and new innovations in the field. Embracing these tips leads to high-quality, long-lasting prints that stand the test of time.