DTF Supplies are the cornerstone of successful direct-to-film projects, offering a practical path from idea to finished garment. From choosing reliable direct-to-film printing gear and DTF printer kits to selecting inks and DTF transfers, this guide helps you start with confidence. With the right DTF inks and compatible transfer materials, colors stay vivid and wash-durable. Whether you are new to the hobby or testing a small business idea, the right supplies streamline your workflow. This beginner guide to DTF will help you master the basics and build a scalable setup.

Viewed through an alternative lens, this is a film-backed textile decoration process where designs are printed onto a transparent sheet and then fused to fabric with heat and pressure. Known as a transfer-on-film technology, it relies on coated PET film, adhesive powders, and a controlled curing step to lock in color. The perspective emphasizes a fast, repeatable workflow suitable for hobbyists and small shops alike, with room to grow into larger runs. By framing the topic as a digital textile transfer workflow, beginners can connect the dots between artwork preparation, color management, and finishing touches without getting overwhelmed.

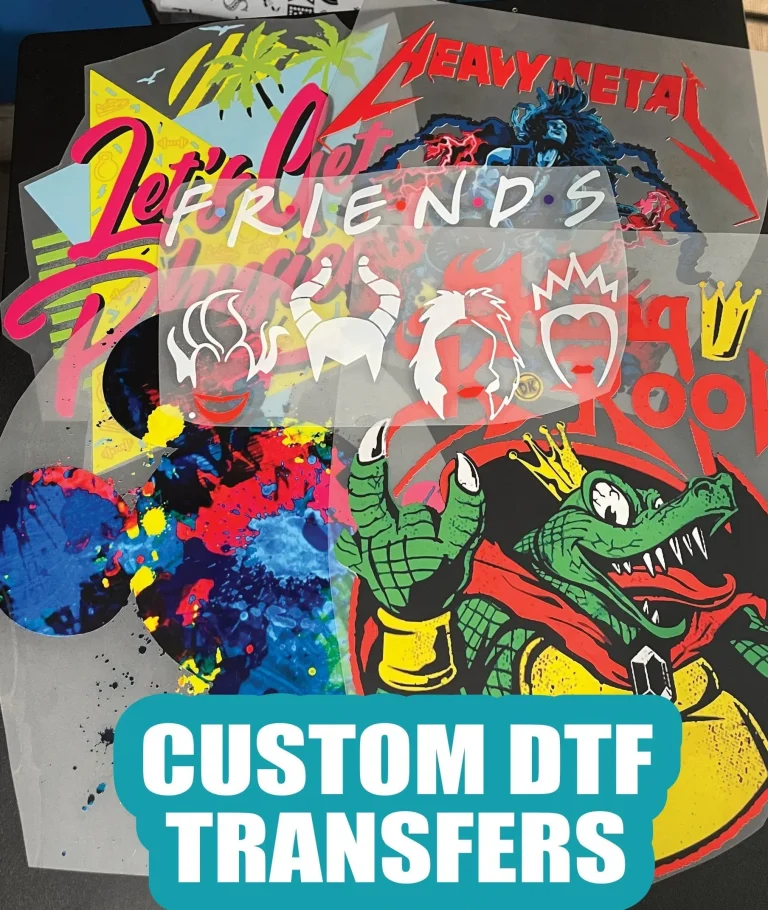

DTF Supplies: Choosing the Right DTF Printer Kits and Inks for Direct-to-Film Printing

Selecting DTF Supplies starts with the right DTF printer kits and compatible inks. When evaluating DTF printer kits, prioritize reliable printhead technology, built-in white ink support for light-on-dark designs, and access to maintenance and warranty. A well-matched kit minimizes downtime and helps you learn the essentials of direct-to-film printing, color management, and the role of adhesive powder in the transfer process.

To begin, treat this phase as a beginner guide to DTF: test a few garments on light and dark fabrics, calibrate color profiles, and practice powder application and heat-press timing. Understanding DTF transfers in practice helps you gain confidence to scale from hobby projects to small orders, and demonstrates why choosing the right DTF inks and compatible media matters for durability and wash-fastness.

Streamlined DTF Workflows: From Design to Transfer with Reliable Film, Powder, and Heat Press

A practical workflow centers on design and color management, with printing following a defined order: white ink first on dark fabrics, then CMYK layers on a PET film. This sequence reflects the core DTF process and keeps direct-to-film printing consistent across runs. A robust routine for applying adhesive powder and curing the film is essential for adhesion, wash durability, and repeatable results when making DTF transfers.

Next, move to transfer prep and finishing: position the film on the garment with heat-resistant tape, set the heat press to the recommended temperature and time, and allow the garment to cool before peeling. Maintain stock control for films, powders, and transfers in a dry environment to prevent moisture-related defects. Document outcomes, adjust ink density or powder application as needed, and build a scalable workflow that supports growth while remaining beginner-friendly.

Frequently Asked Questions

What are the essential DTF supplies for a beginner starting with direct-to-film printing?

Start with core DTF supplies: a reliable DTF printer kit (with white ink support for light-on-dark designs), DTF inks (water-based pigment inks with a dedicated white ink channel), PET film sheets, adhesive powder, and a compatible heat press. Add transfer materials (transfer sheets) and finishing tools (silicone mats, teflon sheets, heat-resistant tape). For a beginner, follow a simple workflow—design and color manage, print white ink first on dark fabrics, apply powder and cure, set up the transfer with heat, press, and cool. Buy from suppliers with solid support and clear warranty, and perform regular maintenance and test prints to dial in color and adhesion.

In a beginner guide to DTF, how should I choose the right DTF printer kits, DTF inks, and DTF transfers for consistent results?

Choose based on compatibility and support. Look for DTF printer kits that provide reliable printhead technology, a proven white ink system, included drivers, and a warranty. Ensure your DTF inks are designed for your printer and include a stable white channel for dark fabrics. Match film sheets and transfer sheets to your chosen inks and heat press workflow, and follow the supplier’s recommended curing times and heat settings. Start with a modest kit and a small batch of films to validate color management using ICC profiles and color targets. Prioritize suppliers with strong technical support and active user communities to troubleshoot variations in curing, adhesion, and wash durability, and to learn about DTF transfers in real-world projects.

| Topic | Key Points |

|---|---|

| What is DTF printing? | DTF printing uses a color-managed process to transfer designs onto textiles via CMYK inks on a PET film. For dark fabrics, a white ink underlay is printed first, followed by adhesive powder application, curing, and heat-press transfer. The result is a durable, color-faithful print that works across many fabrics and often requires a lower upfront investment than some alternatives. |

| Why DTF is a solid choice for beginners | – Simpler workflow: more forgiving than DTG for small runs and mixed fabrics – Versatility: suitable for a wide range of fabrics and colors, including darks with white ink – Cost-effectiveness: affordable starter kits and consumables – Modifiability and scalability: designs can be adjusted as you grow – Moderate equipment footprint: fits in a home workshop for beginners |

| Key DTF supplies every beginner should know |

|

| Getting started: a practical workflow for beginners |

|

| Common mistakes and how to avoid them |

|

| Care and maintenance for long-term performance |

|

| Cost considerations and planning for growth |

|

| Choosing the right supplier and building support networks |

|

Summary

DTF Supplies form the backbone of successful direct-to-film printing projects. By understanding the core components—DTF printer kits, inks, film sheets, adhesive powders, and heat press equipment—you can design a practical, scalable workflow that produces vibrant, durable prints. With careful color management, consistent powder application, and attention to heat and pressure, beginners can achieve professional results and steadily grow their DTF capabilities. Remember, the key is to start with solid supplies, practice regularly, and learn from each print. As you expand your lineup and refine your technique, you will unlock new possibilities in wearable art, custom merchandise, and on-demand printing with confidence.