DTF printing, short for Direct-to-Film printing, is rapidly transforming the landscape of textile customization. This innovative technique allows designs to be printed onto a special film and then heat-transferred onto various fabrics, making it an appealing choice for custom apparel printing. As the DTF market growth continues to accelerate, more businesses are recognizing the DTF printing advantages, which include efficiency, versatility, and vibrant outputs. Additionally, this method aligns with the trend towards sustainable printing methods, appealing to environmentally conscious consumers and brands alike. In this comprehensive guide, we will delve into all facets of DTF printing, uncovering its potential to reshape the future of apparel decoration.

Direct-to-Film printing, often referred to as DTF printing, encompasses a groundbreaking approach in the world of fabric printing. This method utilizes a unique transfer film that allows for intricate designs to be applied to a wide variety of textiles, setting it apart from more established options like screen printing and Direct-to-Garment methods. By focusing on custom apparel production, businesses leverage the efficiency and quality that come with this innovative printing technique. Furthermore, as brands look for more sustainable printing methods, DTF printing stands out as an eco-friendlier alternative, reinforcing its relevance in today’s market. This exploration of direct-to-film technology will shed light on its diverse applications and growing popularity among creators and businesses alike.

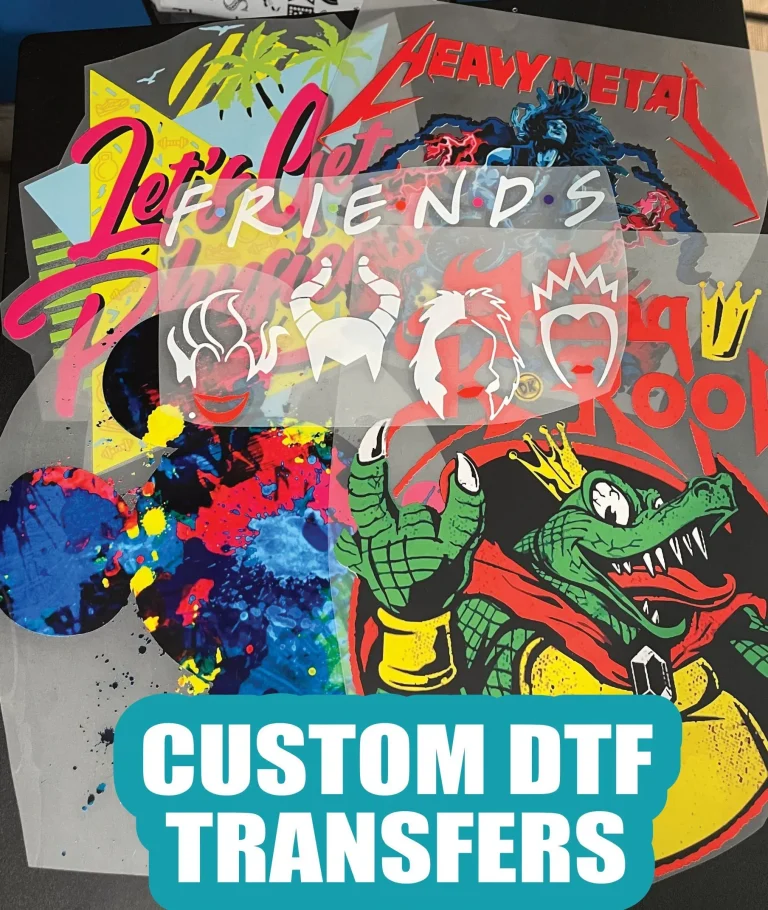

Exploring the Advantages of DTF Printing

DTF printing has surged in popularity, primarily due to its numerous advantages over traditional methods. One of the most significant benefits is the vibrant color reproduction it offers. This process allows for detailed designs to be printed onto a specialized film, preserving the original artwork’s quality. As a result, businesses can produce custom apparel printing that stands out in a saturated market. Additionally, DTF printing is compatible with a variety of fabric types, further enabling creative freedom in design and product offerings.

Another advantage of DTF printing is its cost-effectiveness, particularly for small businesses. Compared to methods like screen printing which often involves high setup costs, DTF requires minimal initial investment and allows for short production runs. This makes it an attractive option for brands aiming to test new designs or respond to consumer demand without committing to large quantities. With the rise of on-demand production, DTF is proving to be a practical solution for those looking to navigate today’s fast-paced fashion landscape.

The Rise of DTF Printing in the Market

As the apparel industry evolves, the DTF printing market is experiencing remarkable growth. This expansion can be attributed to the increasing consumer appetite for personalized and unique designs. With more businesses leveraging DTF technology, there is a notable shift in how brands approach custom apparel printing. Reports indicate that the accessibility of DTF technology allows even small startup companies to enter the market, effectively democratizing custom garment production.

Furthermore, the rise of e-commerce has bolstered the demand for DTF printing solutions. Online platforms that focus on unique fabrics and designs are finding success by incorporating DTF printing into their offerings. This technology not only enhances product quality but also streamlines production processes, allowing businesses to fulfill orders quickly and efficiently. As consumers continue to seek distinct apparel, the DTF printing market is set to flourish.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is an innovative method where designs are printed onto a special film. This film is then applied to textiles using heat and pressure, resulting in high-quality, vibrant prints that adhere well to a variety of fabrics such as cotton and polyester. This process stands out from traditional methods like screen printing due to its versatility and efficiency.

What are the advantages of DTF printing over traditional methods?

DTF printing offers several advantages, including higher print quality, the ability to work on diverse fabrics, and lower setup costs compared to traditional methods like screen printing. It also supports smaller production runs, making it ideal for custom apparel printing. Additionally, many DTF inks are eco-friendly, aligning with sustainable printing methods and reducing environmental impact.

How is the DTF printing market growing in recent years?

The DTF printing market is experiencing rapid growth due to increasing consumer demand for customizable apparel and on-demand printing services. Small businesses are adopting DTF technology to efficiently meet these needs, benefiting from its lower investment requirements and operational convenience, which encourages innovation and competition in the custom apparel sector.

What are the eco-friendly benefits of using DTF printing?

DTF printing is considered a sustainable printing method as it utilizes less water and energy compared to traditional textile printing techniques. The inks used in DTF printing are often formulated to be environmentally safe, making it an attractive option for brands aiming to reduce their carbon footprint while still providing durable and vivid prints on textiles.

What types of fabrics can be printed using DTF technology?

DTF printing is highly versatile and can be used on a wide range of fabrics including cotton, polyester, and fabric blends. This adaptability allows businesses to cater to various market segments such as sportswear, fashion, and promotional items, providing ample opportunities for custom apparel printing across different applications.

What challenges should businesses be aware of when adopting DTF printing?

While DTF printing offers numerous benefits, challenges include the need for precision in temperature and pressure during the transfer process. Additionally, investing in high-quality printers and materials is crucial for achieving optimal results. Businesses must prioritize training to ensure staff are skilled in the techniques required for successful DTF printing, avoiding pitfalls that may affect quality.

| Aspect | Details |

|---|---|

| Understanding DTF Printing | A modern printing technique transferring designs onto textiles using a special film, known for vibrant imagery and versatility. |

| Technological Advancements | Improved print quality and eco-friendly inks, leading to enhanced durability and application scope. |

| Market Growth | Growing demand for customizable apparel propels small businesses to adopt DTF printing for its cost-effectiveness and operational ease. |

| Eco-Friendly Aspects | Lower water and energy consumption make DTF a sustainable alternative, appealing to eco-conscious brands. |

| Application Versatility | Able to print on various fabrics, including cotton and polyester, suitable for diverse products like sportswear and promotional items. |

| Challenges and Considerations | Precision in temperature and pressure is vital; businesses need high-quality equipment and training for optimal results. |

Summary

DTF printing is revolutionizing the textile industry by providing an innovative solution for vibrant and detailed fabric imaging. This technique not only caters to the increasing consumer demand for customizable apparel but also promotes sustainable practices with its lower environmental impact. As the market expands, businesses that embrace DTF printing can differentiate themselves through versatility and eco-friendly choices. While challenges in precision and equipment investment exist, they are outweighed by the immense opportunities for growth and profitability. Therefore, DTF printing stands as a frontrunner in shaping the future of apparel decoration.