In the rapidly evolving world of fashion, DTF printing, short for Direct-to-Film printing, is emerging as a game-changing technology for custom apparel printing. This innovative method stands out due to its ability to deliver high-quality designs directly onto various fabrics with remarkable efficiency and durability. What makes DTF particularly fascinating is its blend of affordability and versatility, allowing both businesses and individual creators to produce stunning apparel without the hefty costs associated with traditional methods. As we explore this advanced printing technology, we will compare DTF with other options like Direct-to-Garment (DTG) printing, highlighting its advantages in terms of sustainability and print quality. The rise of DTF printing is not just about aesthetics; it’s also a significant shift towards eco-friendly practices in the printing industry, making it a pivotal topic in modern custom apparel printing.

Direct-to-Film printing, often referred to as DTF, is gaining traction as a leading method in bespoke garment decoration. Known for its seamless ability to transfer intricate designs onto fabric, this technique is revolutionizing how apparel is produced and personalized. Unlike conventional printing methods that can be cumbersome and resource-intensive, DTF presents a streamlined solution that meets the demands of both large-scale operations and small businesses alike. Additionally, this approach helps push the boundaries of sustainable printing methods, proving advantageous in today’s environmentally conscious market. As we delve deeper into DTF and its comparison with Direct-to-Garment printing, the advantages of this modern technology will become increasingly clear.

Understanding DTF Printing Technology

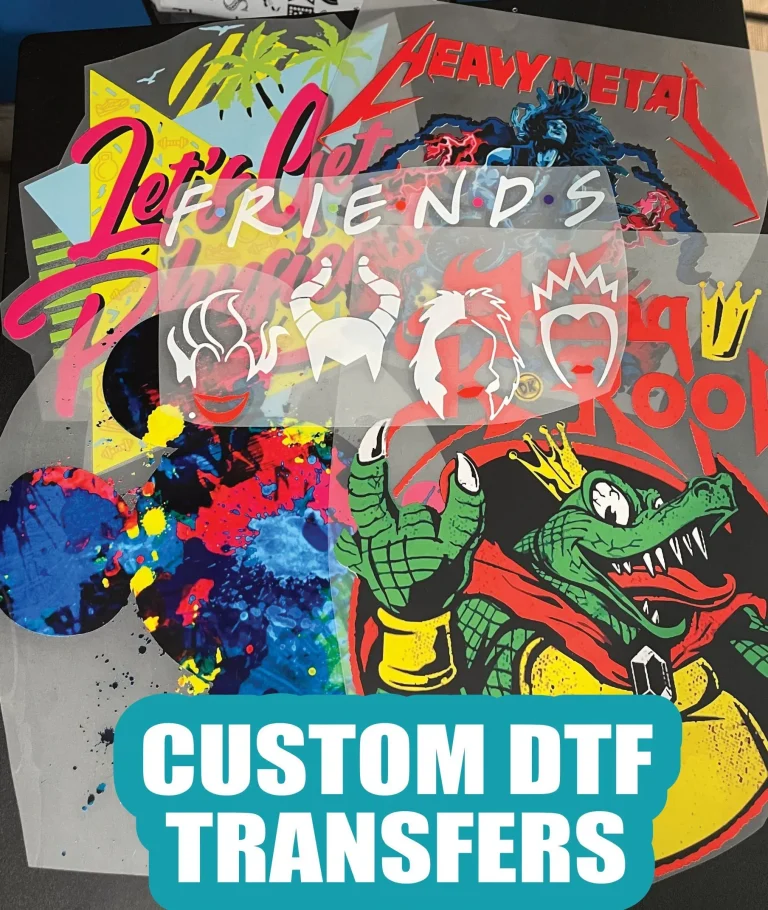

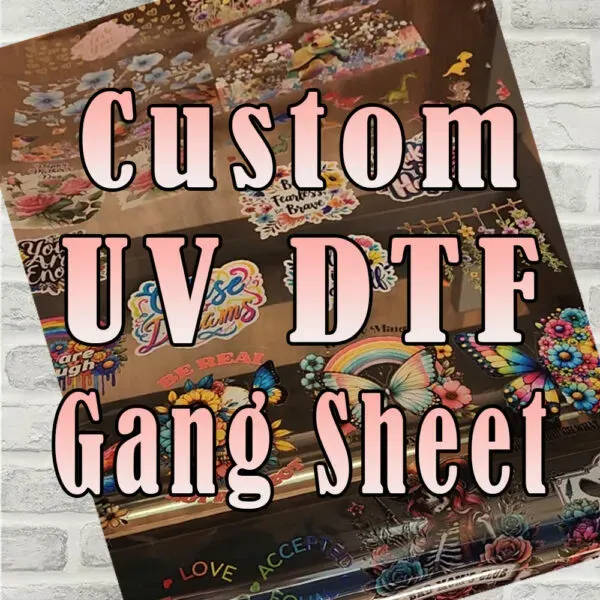

DTF printing, or Direct-to-Film printing, represents a significant leap forward in the world of custom apparel printing. This cutting-edge technology works by transferring designs from a specialized film onto fabric with remarkable precision. Unlike traditional screen printing methods, which often involve a lengthy preparation process and can be costly, DTF printing simplifies the setup by requiring only a printer and heat press. This streamlined approach not only reduces initial costs but also allows for greater flexibility in production, making it an ideal solution for businesses aiming to quickly adapt to evolving market trends.

Moreover, DTF technology has been crafted to achieve exceptional print quality across a variety of materials, including cotton, polyester, and blends. With its capacity to produce vivid colors and intricate details, DTF printing caters to a wide spectrum of customer needs, from eye-catching graphics on t-shirts to detailed logos on promotional apparel. The durability of DTF prints, which withstand multiple washes while retaining their vibrancy, further solidifies its reputation as a lasting solution for custom apparel.

Advantages of DTF vs Traditional Printing Methods

One of the most notable advantages of DTF printing is its efficiency compared to traditional methods like DTG and screen printing. In screen printing, the setup process can be labor-intensive, requiring screens to be prepared for each color, making it less ideal for smaller runs or intricate designs. DTF printing, on the other hand, eliminates this cumbersome process, allowing businesses to produce high-quality prints in a fraction of the time. This efficiency is particularly beneficial for order fulfillment in today’s fast-paced market, where consumers increasingly demand quick turnaround times.

When comparing DTF with Direct-to-Garment (DTG) printing, both techniques offer unique benefits. DTG excels with detailed designs and can print directly onto garments, but it often struggles with speed and fabric compatibility, especially for larger orders. DTF addresses these limitations, providing a versatile and rapid solution that can handle diverse materials at an impressive scale. As more printers evolve and incorporate this technology, businesses are likely to recognize DTF printing as a superior option for their custom apparel needs.

Sustainability in DTF Printing Practices

In an age where eco-friendliness is vital, DTF printing stands out as a sustainable alternative to traditional printing methods. The process generally uses less water and fewer chemicals than screen printing, adopting greener practices that resonate with environmentally conscious consumers. This shift toward sustainable production is not only beneficial for the planet but also positions brands favorably in a market increasingly centered around ethical consumerism.

Furthermore, the inks used in DTF printing often feature eco-friendly formulations, contributing to lower environmental impact during the production process. These sustainable printing methods help brands align with customer values, promoting their commitment to reducing waste and environmental footprint. As consumers become more discerning about the sustainability of their purchases, businesses adopting DTF technology can improve their market positioning and attract a growing base of environmentally minded customers.

Advancements in DTF Technology

Technological advancements in DTF printing have accelerated its acceptance and prominence in the custom apparel industry. Recent innovations have led to the development of faster printers with lower operational costs that deliver high-quality outputs. These improvements make DTF a viable option for anyone looking to enter or expand within the custom apparel market, offering competitive advantages over traditional printing methods.

Additionally, user-friendly interfaces introduced in modern DTF printers lower the learning curve for newcomers, enabling even small businesses and independent creators to harness this technology with ease. As printing technology advances, it provides opportunities for personalization and customization on a scale not easily achievable through older techniques, paving the way for a new era in apparel production.

The Versatility of DTF Printing Applications

The versatility of DTF printing opens a wealth of possibilities for various applications beyond typical t-shirt printing. From unique merchandise for events to personalized items tailored to individual customers, DTF has emerged as a multi-faceted tool in the custom clothing market. Its ability to accurately reproduce vibrant designs on diverse fabrics allows brands to cater to specific audience demographics, enabling special edition runs that appeal to niche markets.

Moreover, businesses are leveraging DTF printing to enhance their branding since it offers the flexibility to adjust designs rapidly according to consumer demand. This adaptability lends itself particularly well to seasonal trends or limited-time promotions, making DTF an integral part of modern marketing strategies. The capability to bring bold, custom designs to life quickly positions businesses to capture the interest of their clientele effectively.

The Future of Custom Apparel Printing with DTF

As the custom apparel market continues to evolve, DTF printing is poised to play a critical role in shaping its future. The combination of its cost-effectiveness, quality, and eco-friendliness appeals to both consumers and businesses alike, driving its adoption across various sectors. Companies that prioritize innovation by integrating DTF technology into their production processes stand to gain a significant edge over competitors relying on outdated practices.

We can expect to see ongoing advancements in DTF printing technology that further enhance print quality, speed, and sustainability. Such innovations will likely push businesses to explore new creative avenues in apparel design and production. As consumer demands for unique, high-quality, and environmentally responsible products continue to rise, DTF represents not just a current trend, but a pivotal force in the future of custom apparel printing.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a method that transfers designs from a specially coated film onto fabrics using a heat process. Unlike traditional methods, DTF printing allows for vibrant colors and high detail on various materials such as cotton, polyester, and blends, making it an excellent choice for custom apparel printing.

How does DTF printing compare to DTG printing?

DTF printing is often compared to Direct-to-Garment (DTG) printing due to both being popular custom apparel printing techniques. While DTG focuses on direct ink application to fabric, DTF prints designs on a film which is then heat-pressed to the fabric, offering advantages in speed, cost, and vibrant output, particularly for larger production runs.

What are the sustainable printing benefits of DTF printing?

DTF printing stands out as a more sustainable printing method, using less water and fewer chemicals than traditional screen printing methods. This aligns with the increasing consumer demand for eco-friendly production practices in custom apparel printing, making it a responsible choice for environmentally-conscious businesses.

What are some key advantages of using DTF printing for custom apparel?

DTF printing offers several advantages including efficiency with quick setup times, high-quality and long-lasting prints, cost-effectiveness with lower startup expenses, and versatility for various fabric types. These benefits make DTF a preferred choice for both small businesses and large-scale production in the custom apparel industry.

What advancements are being made in DTF printing technology?

Recent advancements in DTF printing technology include improved printer models that provide faster printing speeds, lower ink costs, and more user-friendly interfaces, enhancing the overall printing experience. These developments help cater to a wider range of users, from hobbyists to professional custom apparel manufacturers.

Can DTF printing be used for small batch production?

Yes, DTF printing is ideal for small batch production due to its quick setup and versatility. It allows businesses to efficiently create custom apparel without the high costs associated with screen printing, making it a popular choice for print-on-demand services and personalizing smaller orders.

| Key Point | Description |

|---|---|

| What is DTF Printing? | A technology that transfers designs from a film onto fabric using specialized inks, suitable for various materials. |

| Key Advantages of DTF Printing | 1. Efficiency and Versatility: Quicker production cycles, suitable for small and large orders. 2. Quality and Durability: Vibrant colors with wash durability that rivals DTG. 3. Cost-Effectiveness: Lower startup costs compared to screen printing. 4. Sustainability: Requires less water and chemicals, aligns with eco-friendly practices. 5. Technological Advancements: New printer models improve speed and efficiency. |

| Comparison with Traditional Techniques | DTF combines benefits of screen and DTG printing without their limitations, making it a versatile choice for businesses. |

| Real-World Applications | Used by brands for custom merchandise, events, and personalized apparel, allowing flexible market adaptations. |

| Future Trends | Growth in custom apparel will further enhance DTF technologies, reducing costs and improving sustainability. |

Summary

DTF printing is rapidly transforming the landscape of custom apparel printing with its innovative features that balance efficiency, quality, durability, and sustainability. With advancements continually being made in this technology and increasing consumer demand for customized clothing, DTF printing is positioned to significantly influence the future of garment design and production. Businesses, whether they are just starting or looking to modernize their production methods, would benefit tremendously by adopting DTF printing to thrive in this dynamic and competitive market.