In recent years, DTF printing techniques, or Direct-to-Film printing, have revolutionized the textile industry, providing a remarkable solution for creating vivid and intricate designs on a wide range of fabrics. This innovative approach allows businesses to produce high-quality custom apparel with efficiency and precision, making it a preferred choice for many small enterprises. As more brands strive to stand out in the marketplace, understanding the advantages of DTF printing and fabric compatibility becomes crucial for success. Additionally, this guide offers valuable DTF print design tips that can elevate the art of fabric printing. Whether you’re a seasoned designer or just starting, mastering these techniques will enable you to harness the full potential of DTF printing.

Direct-to-Film printing, commonly referred to as DTF printing, is taking the custom apparel industry by storm with its unique ability to deliver vibrant designs across various fabric types. This method stands out for its versatility and efficiency, allowing both small businesses and established brands to create personalized garments that reflect individual style. With a focus on fabric compatibility and advanced printing techniques, enthusiasts can explore a multitude of options to enhance their production capabilities. As we delve into the essentials of DTF techniques, including effective design strategies and technological advancements, you’ll find that this printing process not only facilitates creativity but also meets the growing demand for custom apparel solutions.

Exploring the Advantages of DTF Printing

DTF printing comes with a plethora of advantages that make it a preferred choice among textile businesses. One of the standout benefits is its ability to print vivid colors and intricate designs on a variety of fabrics. This versatility means brands can cater to diverse consumer preferences, producing everything from custom t-shirts to promotional items. Additionally, DTF printing maintains a competitive edge due to its cost-effectiveness; the initial investment is significantly lower than traditional methods like screen printing, facilitating entry for new businesses into the market.

Moreover, the durability of DTF prints cannot be overstated. Recent research indicates that prints withstand multiple washes without fading or deteriorating, making them suitable for everyday wear. This quality assures customers of the long-term value of their purchases. Furthermore, as consumers increasingly seek personalized apparel options, DTF printing’s capability for short-run production aligns perfectly with current trends, providing businesses with a viable solution to meet unique customer demands.

Understanding Fabric Compatibility with DTF

One of the greatest advantages of DTF printing is its compatibility with a wide range of fabrics. From cotton to polyester, DTF technology excels in creating stunning prints on various textile surfaces. Cotton, for instance, is known for its ability to absorb inks well, providing vibrant and detailed prints. Polyester also offers a smooth surface ideal for high-quality images, while cotton-poly blends present a perfect combination of durability and print compatibility.

To maximize the effectiveness of DTF prints, many businesses are experimenting with various fabric treatments. Pre-treatment chemicals can enhance the adhesion of the ink to the fabric, which is crucial for ensuring the longevity of the designs. By understanding the properties of different fabrics, printers can tailor their approach to deliver the best results, thereby expanding their offerings in the competitive custom apparel market.

Key DTF Print Design Tips

When creating designs for DTF printing, there are several key techniques that can significantly enhance the final outcome. Focus on developing high-contrast designs that utilize vibrant color palettes and intricate details, as these elements transfer beautifully through the DTF process. Designers should utilize software that is specifically optimized for DTF printing, enabling them to create clear, compelling graphics that leverage the technology’s advantages.

Additionally, employing tools such as Adobe Illustrator or CorelDRAW allows designers to bring flexibility and creativity into their projects. These programs facilitate the creation of vectors and high-resolution images, which are crucial for ensuring clarity in the final print. By exploring design innovations and considering the strengths of the DTF printing technology, creators can produce standout designs that captivate consumers.

Recent Developments in DTF Technology

The world of DTF printing is dynamic, with recent technological advancements significantly enhancing both print quality and efficiency. For example, improved ink formulations have emerged that enhance durability and vibrancy while also catering to environmentally-conscious consumers looking for sustainable options. These innovations not only improve the aesthetic output but also meet the growing demand for eco-friendly products within the textile industry.

In addition to advanced inks, updated printing equipment has made a notable impact on the DTF printing landscape. Modern printers are now capable of achieving higher resolutions and faster printing speeds, facilitating quicker turnaround times. This technological evolution meets the demands of both bulk orders and customized prints, ensuring that businesses can thrive in a competitive market while delivering exceptional quality to their customers.

Current Market Trends in DTF Printing

As the popularity of DTF printing grows, several market trends are driving its adoption among small businesses and fashion brands. The increasing consumer demand for personalized apparel and promotional items has made DTF printing an appealing option. It allows businesses to capitalize on the trend of individual expression, providing unique clothing and accessories that resonate with consumers.

Furthermore, reports suggest that more enterprises are turning to DTF printing because it requires a lower upfront investment compared to traditional methods like screen printing. This accessibility enables new fashion designers and small business owners to enter the market with minimal financial risks. As these trends continue to flourish, DTF printing is likely to establish itself as a dominant technique in custom apparel printing, catering to the evolving needs of consumers.

Sustainability and DTF Printing Practices

With an ever-increasing focus on sustainability within the textile industry, DTF printing practices are evolving to meet these challenges. One significant trend emerging from this focus is the development of eco-friendly inks and materials used in DTF printing. These inks not only offer high-quality results but are also formulated to minimize environmental impact, appealing to consumers who prioritize sustainability in their purchasing decisions.

Additionally, the DTF printing process itself contributes to reduced waste compared to traditional printing methods. With DTF, businesses can produce prints on demand, mitigating excess inventory and minimizing the carbon footprint associated with overproduction. As the demand for responsible fashion grows, the integration of sustainable practices in DTF printing could enhance brand loyalty and consumer trust.

Frequently Asked Questions

What are the main advantages of DTF printing compared to other printing methods?

DTF printing offers several key advantages, including versatile fabric compatibility, vibrant color reproduction, and durability. Unlike methods like screen printing, DTF allows for intricate designs with high detail and is suitable for a wide range of materials such as cotton, polyester, and blends, making it ideal for custom apparel printing.

What type of fabrics are best suited for DTF printing?

DTF printing is compatible with various fabric types, including cotton, polyester, and fabric blends. These materials absorb ink well, allowing for rich color vibrancy and detail in prints. Additionally, companies are experimenting with pre-treatment chemicals to enhance adhesion and durability of the DTF prints on these fabrics.

Can you share some DTF print design tips for better results?

To achieve optimal results with DTF printing, focus on creating high-contrast designs that feature vibrant colors and clear outlines. Utilize design software like Adobe Illustrator or CorelDRAW that are tailored for DTF printing, and ensure your graphics are well-defined to enhance clarity and visual appeal post-transfer.

How does DTF printing ensure durability in printed fabrics?

DTF printing incorporates advanced ink formulations that are designed for durability and color retention. Recent research indicates that DTF prints can withstand numerous laundry cycles while maintaining quality, making them a favored choice for custom apparel that requires long-lasting designs.

What technological advancements have improved DTF printing techniques?

Recent advancements in DTF printing technology include enhanced ink formulations for eco-friendliness and higher durability, along with modern printers that provide improved resolution and faster printing speeds. These improvements allow for intricate designs and quicker production times, meeting the needs of both large and small printing demands.

Is DTF printing a cost-effective option for small businesses launching custom apparel?

Yes, DTF printing is considered a cost-effective option for small businesses because it requires a lower initial investment compared to traditional methods like screen printing. With its flexibility in design and material compatibility, DTF printing allows businesses to offer personalized and on-demand products catering to modern consumer preferences.

| Key Point | Details |

|---|---|

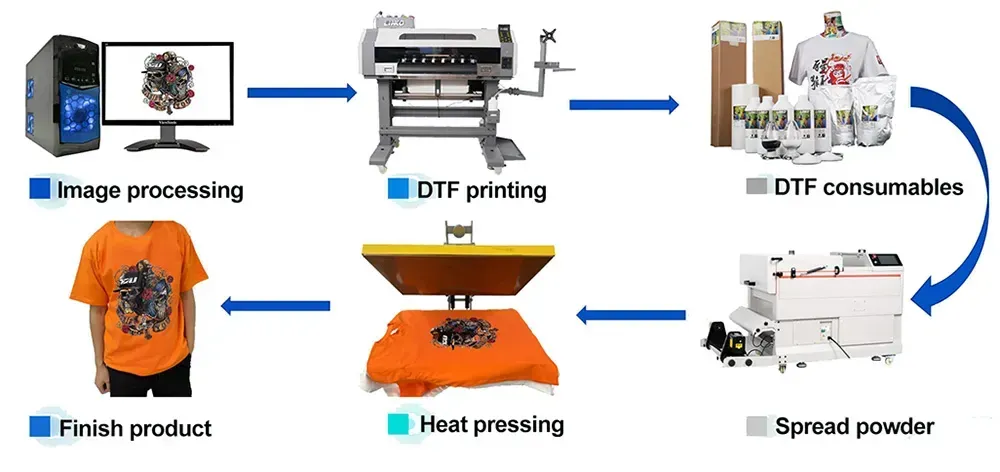

| Understanding DTF Printing | DTF printing transfers designs from a specialized film onto various fabrics, making it ideal for custom apparel. |

| Recent Developments in Technology | Advancements in ink formulations and printing equipment have improved quality and efficiency. |

| Design Techniques for DTF Printing | High-contrast designs are favored, utilizing software like Adobe Illustrator and CorelDRAW for optimal results. |

| Fabric Compatibility | Versatile suitability for various fabrics like cotton, polyester, and blends. |

| Durability Testing | Studies show DTF prints withstand multiple washes without significant quality loss. |

| Market Trends | DTF printing is growing due to its lower investment compared to traditional methods and the demand for personalization. |

Summary

DTF printing techniques have revolutionized the textile industry by allowing for high-quality, customizable designs on various fabrics. This printing method integrates advanced technology that enhances both vibrancy and durability of prints, catering perfectly to the growing trend of personalized apparel. As businesses and designers embrace DTF printing, they can capitalize on its versatility and lower initial investment, all while meeting the expectations of modern consumers for unique and lasting products. Mastering DTF techniques ensures any apparel brand can thrive in the evolving marketplace.