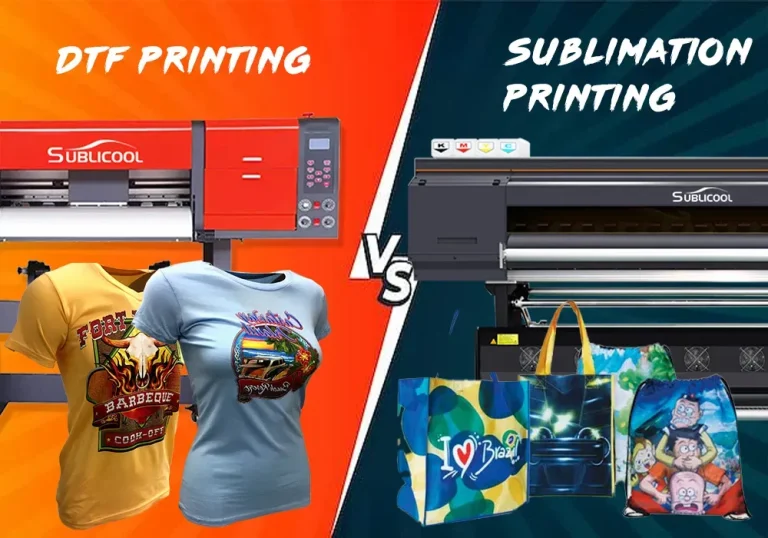

DTF printing, or Direct-to-Film printing, has revolutionized the way we produce vibrant designs on textiles, providing a reliable method for creating striking visuals that stand the test of time. This innovative printing technique offers numerous advantages, such as superior durability and versatility, making it ideal for various fabrics from cotton to polyester blends. As we dive into the art of DTF printing, we will also uncover essential DTF printing tips that can significantly enhance the quality of your projects. By understanding the right DTF printing materials and mastering DTF heat press techniques, you can streamline your workflow and achieve remarkable results. Join us as we explore expert advice to boost your DTF printing success and elevate your garment production game.

Direct-to-Film printing (DTF) has emerged as a cutting-edge solution for creating eye-catching graphics on different fabrics. This technique harnesses advanced printing technology, allowing for seamless transfers of designs with exceptional quality. By mastering the nuances of this method, including selecting appropriate materials and implementing effective heat press techniques, enthusiasts can unlock new potential in their printing projects. Additionally, understanding vital practices, such as ink adhesion and fabric preparation, can dramatically influence the final outcome. Let’s embark on a journey to discover invaluable tips and tricks that will take your fabric printing to the next level.

Maximizing DTF Printing Quality with Superior Materials

When embarking on DTF printing projects, the quality of materials used can significantly influence the outcome. For optimal results, it’s essential to select high-grade DTF films and inks. Inferior materials might save costs initially, but they often lead to poor print quality, dull colors, and short-lived designs. Upscale brands such as Teflon and Arthaus are preferred by industry professionals for their reliability and vibrant color outputs. These products ensure that the printed designs not only look great but also endure extensive wear and washing, making them ideal for commercial use.

Investing in superior DTF printing materials can also heighten your production efficiency. With high-quality inks that have excellent adhesion properties, you can minimize the occurrence of misprints and defective productions. Additionally, utilizing premium films reduces the chances of peeling and fading, ensuring that the final garments meet customer expectations. By prioritizing material quality, you create a foundation for successful DTF printing projects, positioning your brand for growth in a competitive market.

Essential DTF Printing Tips for Effortless Results

Successful DTF printing goes beyond merely operating the equipment; it involves understanding the nuances of the process. For instance, optimizing your printer settings is crucial. This includes adjusting parameters like speed, temperature, and even ink flow according to the specific materials you are using. Regularly calibrating your printer will help you achieve stunning prints every time. Conducting test prints can further refine these settings, allowing you to discover the ideal configurations for your films and inks.

Moreover, knowing the right techniques for adjusting printer settings can significantly impact the vibrancy and detail of your final designs. Experimenting with various combinations can lead you to find the perfect balance that resounds with your customer’s expectations. Remember, solid knowledge and execution of printer settings can enhance the aesthetic appeal of your DTF prints while also boosting your operational efficiency.

The Importance of Pretreating Fabrics for DTF Success

Pretreating fabrics is a vital step that should not be overlooked in the DTF printing process. It ensures that inks adhere properly, allowing for vibrant colors and clarity in print. For example, cotton fabrics often require a specialized pretreatment spray that enhances the bonding of the ink to the material, ultimately improving durability and appearance. By adequately preparing the fabric, you mitigate the risk of poor adhesion and ink bleeding, which can compromise print quality.

Different types of fabrics will necessitate specific pretreatment approaches. Polyester fabrics may thrive under different conditions compared to cotton or blends. Researching and applying the correct pretreatment methods for your fabric choices will ensure that each print meets the high standards synonymous with DTF printing. This attention to detail not only uplifts the quality of your prints but also instills confidence in your customers regarding the longevity of the products they purchase.

Mastering Heat Press Techniques for Flawless Transfers

Heat application is a cornerstone of the DTF printing process, making mastering heat press techniques essential for achieving flawless transfers. Ensuring that your heat press is correctly calibrated for both temperature and pressure can drastically affect the adhesion of your prints. Overheating or applying uneven pressure can lead to undesirable results like fading or complete print failures. Hence, utilizing a heat press thermometer and conducting preliminary tests for temperature settings is an effective strategy.

Furthermore, making adjustments to the duration of heat application can also enhance the quality of prints. Test runs can help you identify the optimal time for different fabric types and designs. By honing your heat press techniques, you not only improve the aesthetic appeal of your products but also their longevity, providing your customers with high-value garments that stand the test of time.

Post-Printing Care for Long-Lasting DTF Prints

After the completion of DTF printing, the care practices you adopt can play a pivotal role in assuring the longevity of your designs. Allowing sufficient curing time—typically a minimum of 24 hours—before washing printed garments is crucial as it helps the ink bond effectively with the fabric. Rushing this process can lead to premature fading and damage, diminishing the quality of your prints.

Moreover, it is equally important to educate customers on proper washing and care instructions. Instructing them to wash garments in cold water and avoid bleach can extend the life of the print. Providing clear care guidelines not only ensures customer satisfaction but also positions your brand as a trustworthy and quality-focused entity in the competitive landscape of DTF printing.

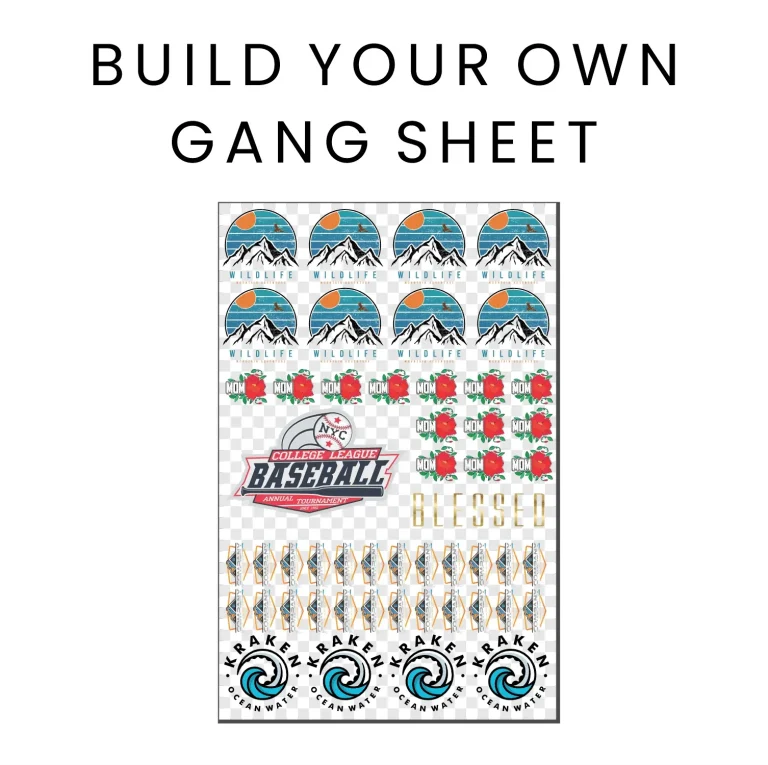

Implementing a Testing Phase for DTF Printing Projects

Incorporating a testing phase into your DTF printing workflow can be a game-changer. Before committing to bulk production, conducting test prints serves as an essential quality check, allowing you to spot potential issues related to film choice, inks, or printer settings. This proactive approach can save you time and resource waste, ensuring that any necessary adjustments are made before the final run.

Moreover, utilizing small sample prints allows for experimentation with different materials and styles, helping you identify what works best for the specific projects at hand. By routinely implementing a testing phase, you foster a culture of quality control that enhances the reliability and appeal of your DTF printing outputs, ultimately benefitting your overall business practices.

Frequently Asked Questions

What are the key benefits of DTF printing compared to traditional printing methods?

DTF printing offers several advantages over traditional methods. It provides vibrant colors, better fabric adhesion, and the versatility to print on various materials like cotton and polyester. Additionally, DTF printing allows for quicker turnaround times and less setup, making it ideal for small runs and custom designs.

What type of fabrics are best suited for DTF printing?

DTF printing works exceptionally well on a wide range of fabrics, including cotton, polyester, and their blends. However, to achieve optimal results, it is essential to pretreat fabrics properly and choose the right inks to enhance adhesion and color vibrancy, ensuring long-lasting prints.

What are some common DTF printing tips for ensuring high print quality?

To achieve high-quality DTF prints, focus on using high-grade films and inks, optimize printer settings, and ensure appropriate fabric pretreatment. Additionally, mastering heat press techniques to apply even temperature and pressure will significantly elevate your print quality and durability.

How do I choose the right DTF printing materials for my projects?

Selecting the right DTF printing materials involves investing in high-quality films and inks from reputable brands. Look for materials that enhance print resolution and color vibrancy. Testing different combinations will also help you find the best match for your specific fabric types.

What critical steps should I follow for post-printing care of DTF prints?

After printing, allow your garments to cure for at least 24 hours to bond the inks properly with the fabric. It is essential to educate customers on proper washing and care procedures, such as avoiding harsh detergents and high heat, to maintain the integrity of the prints long-term.

Can I perform test prints for DTF printing, and why are they necessary?

Yes, conducting test prints is crucial in DTF printing. It allows you to assess print quality, make necessary adjustments to settings or materials, and identify any issues before beginning full-scale production. Test prints help ensure that every detail in your design is perfect and ready for customer satisfaction.

| Key Points | Details |

|---|---|

| Understanding DTF Printing | DTF printing involves transferring designs from a special film onto fabrics using a heat press, adaptable to various materials. |

| Quality of Film and Inks | High-quality materials are crucial for vibrant and durable prints. Invest in reputable brands like Teflon and Arthaus. |

| Printer Settings Optimization | Fine-tune printer settings, such as temperature and speed, through test prints to achieve optimal print quality. |

| Pretreating Fabrics | Use pretreatment sprays appropriate for the fabric type to improve ink adhesion and vibrancy. |

| Heat Press Techniques | Ensure correct heat and pressure settings with a thermometer for successful adhesion of prints. |

| Post-Printing Care | Follow curing times and washing instructions to maintain print durability and avoid fading. |

| Testing and Sampling | Conduct test prints to identify issues early and ensure quality before full production. |

Summary

DTF printing has become a vital technique for garment manufacturers, enabling them to create stunning and resilient designs. To achieve the best results, focus on high-quality materials, fine-tune your printer settings, and properly pretreat your fabrics. It’s essential to master heat press techniques and adhere to post-print care instructions to ensure longevity. Incorporating testing and sampling into your workflow helps in identifying any potential issues early. By following these expert tips, businesses can optimize their DTF printing projects and produce output that not only meets but exceeds customer expectations.