DTF Printing has transformed how designers and small brands bring vibrant artwork to apparel and textiles. As a form of direct-to-fabric transfers, this approach leverages a specialized film and adhesive system within the DTF printing process. This method blends digital design freedom with durable, vibrant results and complements modern fabric printing techniques across cotton, blends, and some synthetics. For many creators, direct-to-fabric transfers open up new possibilities for customization and on-demand production. This guide explains how it works, why it’s gaining traction, how DTF vs DTG compares, and outlines DTF transfer advantages to help you decide if it’s right for your projects.

Another way to describe this method is as a direct-to-fabric transfer technology that uses a PET film and adhesive powder. In practice, it’s an ink-on-film system where the design is printed, cured with powder, and fused to the fabric with heat. This framing highlights the flexibility of fabric printing techniques that work across cotton, blends, and some synthetics, with strong color and durability. For brands weighing options, the comparison with DTG or screen printing becomes clearer when considering setup costs, lead times, and run sizes.

DTF Printing: A Modern Approach to Fabric Design

DTF Printing is a modern approach that enables designs to be transferred onto fabric using a specialized film and adhesive system. The process begins with printing the design on a polyester PET film, followed by applying an adhesive powder, curing, and then transferring the image to the fabric with heat and pressure. This method blends the flexibility of digital design with durable, vibrant results that work on a wide range of fabrics, including cotton, blends, and some synthetics. For many creators, Direct-to-Fabric transfers open up new possibilities for customization and on-demand production.

The DTF printing process supports color-rich artwork and complex gradients, making it a versatile option for fashion brands, band merch, school uniforms, and customized home textiles. Its reliance on a transfer film and adhesive system allows multi-fabric compatibility without extensive pretreatment. As a result, designers can leverage fabric printing techniques that keep production lean while preserving design integrity across different materials.

DTF vs DTG: How Direct-to-Fabric Transfers Compare

DTF printing offers concrete advantages in terms of fabric versatility, often delivering durable prints on blends and darker fabrics without heavy pretreatment. DTG, by contrast, shines for ultra-soft hand-feel and high-detail prints on light-colored fabrics but may require pretreatment and can be more sensitive to fabric type. Understanding these differences helps designers choose between direct-to-fabric transfers and directly to garments based on substrate, texture, and end-use.

Key differences include substrate compatibility, pretreatment needs, and the perceived feel of the print. DTF transfer advantages include broader fabric compatibility and reduced setup for multi-color designs, while DTG excels in soft hand and fine detail on suitable fabrics. When deciding, consider whether the project prioritizes versatility and speed across fabrics or exceptional softness on light textiles, and evaluate how each method aligns with your fabric printing techniques and production constraints.

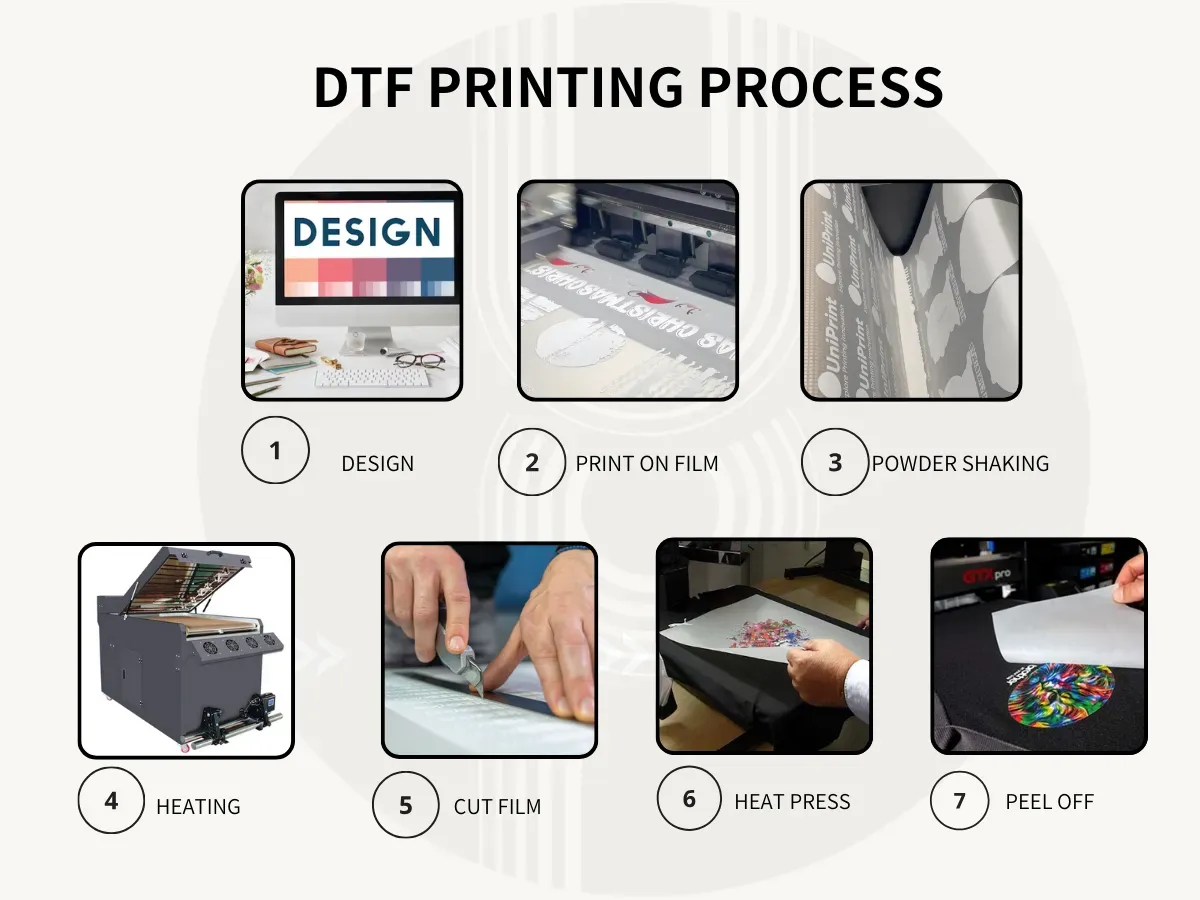

DTF Printing Process Explained: From Design to Finished Transfer

The DTF printing process begins with design and preparation: start with a high-resolution design, using vector or high-quality raster art to ensure crisp edges. Color management and ICC profiles help maintain consistency across prints, which is essential for reliable results in the DTF printing process.

The next steps involve printing on PET film, applying adhesive powder, curing, and then transferring to fabric. Multi-ink alignment and precise registration ensure the final transfer sits correctly on the garment, while the heat press applies specific temperature, time, and pressure to fuse the ink and adhesive to the fabric. Peeling and curing finish the process, leaving a durable image bonded to the textile.

Fabric Compatibility and Performance with DTF

Direct-to-Fabric transfers show strong color fidelity and adaptability across fabrics such as cotton, cotton-poly blends, and some polyesters. This makes DTF an attractive option for designers seeking vibrant garments and home textiles without sacrificing fabric performance or flexibility in design.

Durability and washability are core considerations. When properly cured and pressed, DTF prints can resist cracking on a wide range of fabrics. However, different materials may respond differently to heat and adhesive, so testing on representative swatches remains a best practice within the fabric printing techniques landscape.

DTF Transfer Advantages for Small Brands and On-Demand Production

DTF transfer advantages include on-demand production capabilities, reduced setup costs, and the ability to print from digital files without expensive screens. This makes it ideal for small brands and one-off runs, allowing rapid prototyping and iteration while maintaining high color fidelity and edge detail.

The workflow integrates smoothly with existing production lines and supports reprintability and archiving of designs. For brands releasing limited editions or running micro-collections, DTF transfers offer a scalable path to on-demand fulfillment with fewer barriers to entry, aligning with modern fabric printing techniques and fast-moving fashion cycles.

Practical Tips for Getting Started with DTF Printing

Begin with quality materials and reliable components: PET film, adhesive powder, curing equipment, and a capable heat press. A solid foundation supports the DTF printing process, while ensuring color fidelity and adhesion across fabrics.

Calibrate color profiles and test on fabric swatches before production. Control heat press parameters (temperature, time, pressure) to match your substrate and adhesive, and plan for layering effects or textures if your design requires metallics or white underbase. Safety considerations and proper ventilation are also important when working with powders and adhesives to maintain a healthy workspace.

Frequently Asked Questions

What is DTF Printing and how do direct-to-fabric transfers work?

DTF Printing uses a PET film to carry designs onto fabrics through direct-to-fabric transfers. The process prints the design on film, applies an adhesive powder, cures it, and then uses heat and pressure to transfer the image onto cotton, blends, and some polyesters. This results in durable, vibrant images with flexible fabric compatibility.

DTF vs DTG: How does the DTF printing process compare to direct-to-garment printing?

DTF printing process transfers ink from a PET film with adhesive, offering broader fabric versatility and lighter pretreatment needs than DTG, which prints directly on fabric and often requires pretreatment for certain fabrics. DTF is well-suited for dark fabrics and varied textiles, while DTG can deliver a softer hand on lighter fabrics.

What are the DTF transfer advantages for designers and small businesses?

DTF transfer advantages include fabric versatility across cotton, blends, and some polyesters, strong color fidelity, on-demand production, and no need for expensive screens. You can reprint designs easily and apply bold images to dark fabrics using the adhesive transfer process.

Which fabric printing techniques work well with DTF Printing and when should you choose it?

DTF Printing pairs well with common fabric printing techniques as a versatile option. It works across cotton, blends, and some synthetics, with quick setup and low waste. Choose DTF when you need on-demand runs, multi-color designs, or prints on darker textiles without lengthy pretreatment.

How can you optimize color accuracy in the DTF printing process?

To optimize color accuracy in the DTF printing process, use color-managed workflows with ICC color profiles, reliable RIP software, and calibrated printers. Printing on PET film with proper alignment and using test swatches helps ensure vibrant gradients and edge definition across fabrics.

What common challenges occur with DTF transfers and how can you prevent them?

Common challenges in DTF transfers include excess powder residue, improper curing, and misalignment. Prevent these by ensuring even powder coverage, tuning heat press temperature and time, and verifying alignment before pressing.

| Topic | Key Points |

|---|---|

| What is DTF Printing? | Direct-to-Fabric transfer using a PET film, adhesive powder, curing, and heat-press to bond the design to fabric. Works on cotton, blends, and some synthetics; offers vibrant, durable results as an alternative to DTG and screen printing. |

| How DTF Printing Works | Design is printed on PET film, coated with adhesive powder, cured, and transferred to fabric using heat and pressure. Followed by peeling the film; multi-ink alignment and post-press curing can improve durability. |

| DTF vs DTG | DTF offers broader fabric versatility and strong color on dark textiles; DTG excels in ultra-soft hand-feel and high-detail on light fabrics but may require pretreatment. DTF usually avoids garment pretreatment, but uses film and powder steps. |

| Advantages | Fabric versatility, vibrant color fidelity and gradients, on-demand production, no dedicated screens, effective on dark fabrics, easy reprints and archiving. |

| Practical Tips | Source quality materials; calibrate color profiles; test on fabric swatches; control heat press parameters; plan layering/textures; follow safety guidelines. |

| Applications & Industry Impact | Popular for fashion brands, band merch, school uniforms, home textiles; supports small-batch customization and rapid e-commerce fulfillment. |

| The Future | Ongoing improvements in inks, films, and adhesion; higher color density and efficiency; broader adoption with lower upfront costs. |

Summary

DTF Printing is a powerful, flexible approach to fabric customization that blends the benefits of digital design with durable, transferable results across a wide range of fabrics. This overview highlights how DTF Printing works, how it compares to DTG, and practical steps to start, guiding designers and small businesses toward informed decisions for on-demand, multi-fabric production.