DTF printing, or Direct-to-Film printing, has emerged as a game-changer in the world of cost-effective printing, particularly appealing to entrepreneurs in the print-on-demand sector. This innovative approach not only streamlines the printing process but also champions sustainability, making it an ideal choice for businesses focused on eco-friendly practices. As this technique continues to evolve, it offers dynamic entrepreneurial printing solutions that enable small businesses to thrive in a competitive landscape. With its affordability and quality, DTF printing empowers creators to bring their vivid designs to life without breaking the bank. In this article, we delve into the multifaceted benefits of DTF printing and how it can transform the way small enterprises operate.

Known also as Direct-to-Film technology, DTF printing is revolutionizing the realm of textile and graphic printing. This modern technique allows for the transfer of intricate designs onto various materials, supporting a diverse range of applications from fashion to promotional items. Many businesses are identifying DTF as a scalable printing solution that caters to both small orders and large-scale production seamlessly. As entrepreneurs increasingly embrace print-on-demand DTF capabilities, they are finding ways to decrease waste while maximizing output quality and customer satisfaction. With its blend of efficiency and eco-friendliness, this printing method positions itself as a leader in the quest for sustainable and cost-effective business practices.

Understanding the Mechanics of DTF Printing

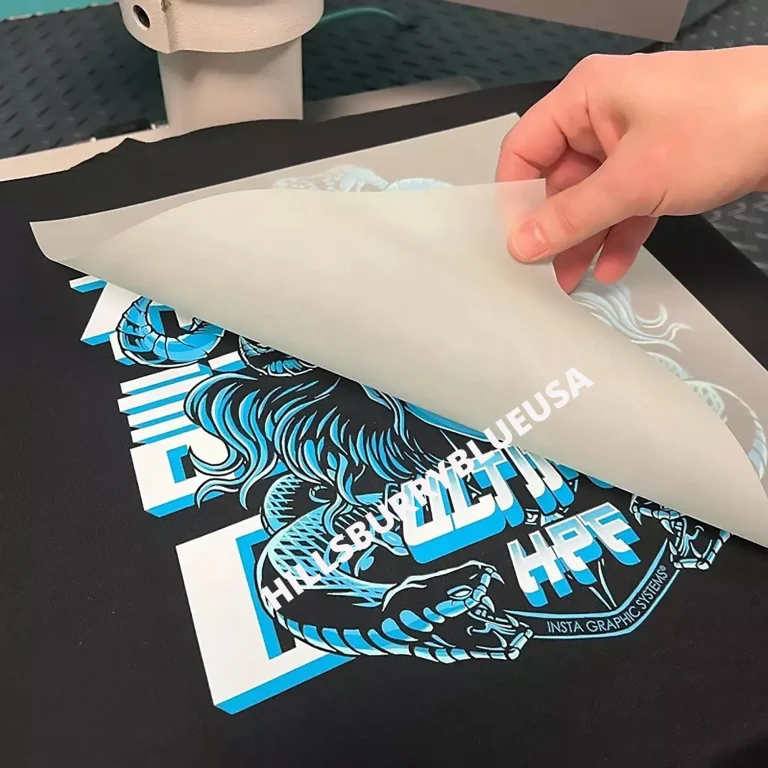

Direct-to-Film (DTF) printing operates through a straightforward yet effective mechanism. The process begins with designing graphics digitally, which are then printed onto a special film using high-quality inks. This film serves as the medium for transferring designs onto textiles. Once the images are printed on the film, they require a heat transfer application that allows the ink to bond securely to the fabric, resulting in vibrant and durable prints. This method’s simplicity is a significant factor in its rising popularity among entrepreneurs keen to establish a niche in the competitive printing market.

What sets DTF printing apart from traditional methods like screen printing is its versatility and speed. Entrepreneurs can personalize or produce small batches of products in record time, which is a vital advantage for print-on-demand services. The technology allows firms to respond quickly to trends and customer demands, maintaining a competitive edge in the market. Moreover, the DTF process significantly reduces waste, aligning with sustainable printing practices that many consumers now prioritize.

The Financial Benefits of DTF Printing for Small Businesses

Cost is a critical consideration for many entrepreneurs entering the printing industry. DTF printing provides a financially viable alternative to traditional printing methods, which often involve high upfront costs and extensive inventory management. For example, the initial investment in a DTF printer is notably lower than that required for a screen printing setup. Entrepreneurs can find DTF printers ranging from $600 to $1,500, compared to the tens of thousands of dollars needed for conventional equipment.

In addition to lower equipment costs, DTF printing offers ongoing savings. The consumable materials—such as inks and transfer films—are relatively economical, allowing business owners to produce high-quality prints for as little as $0.50 to $2.00 per unit. This cost-effectiveness enhances profit margins, enabling small businesses to thrive without the burden of significant financial strain, thus fostering a lean entrepreneurial approach.

Overall, the financial benefits of DTF printing are compelling for small businesses. By lowering both startup and operational costs, this method empowers entrepreneurs to preserve cash flow for other critical aspects of their operations, paving the way for sustainable growth.

Exploring Sustainable Printing Practices with DTF

Sustainable printing is no longer just a trend; it is a necessity for businesses seeking relevance in today’s eco-conscious marketplace. DTF printing technology inherently aligns with sustainability efforts by significantly reducing material waste during the printing process. Unlike traditional methods, which often require significant resources in setup and cleanup, DTF printing minimizes excess, operating efficiently with lower consumption of inks and materials.

The shift towards sustainable practices not only enhances a company’s environmental credentials but also appeals to a growing demographic of consumers who prioritize eco-friendly products. By adopting DTF printing, entrepreneurs can position their brands as socially responsible while tapping into a lucrative market niche. This integration of sustainability with profitability is crucial for entrepreneurs looking to build lasting relationships with modern consumers.

The Versatility of DTF Printing in Entrepreneurial Ventures

Versatility is one of the significant advantages of DTF printing, enabling entrepreneurs to explore a variety of product offerings without the common limitations of traditional printing methods. Whether it’s apparel, accessories, or promotional items, DTF technology accommodates different materials and substrates, making it suitable for a broad range of applications. This capability is particularly beneficial in a print-on-demand model, where customization and quick turnaround times are paramount.

Moreover, entrepreneurs can experiment with various designs and products without incurring substantial risks or costs, thanks to the low-cost nature of DTF operations. The ability to produce everything from intricate graphics to personalized items allows businesses to cater to diverse consumer interests and trends, thereby enhancing their market presence and facilitating growth opportunities.

Market Dynamics and Opportunities in DTF Printing

The rise of DTF printing reflects the broader shifts in consumer behavior towards personalized products and quick delivery. Entrepreneurs tapping into this market can take advantage of the growing trend for custom prints and limited-edition goods. As more customers seek unique items that express individuality and style, DTF printing provides a perfect solution, allowing small business owners to meet these demands efficiently.

Additionally, the print-on-demand model facilitated by DTF technology allows entrepreneurs to operate without the need for large inventories, reducing financial risk. This agility enables them to adapt quickly to changing market trends and consumer preferences, thus establishing a sustainable business model that has the potential for long-term viability in a competitive landscape.

Cultivating Customer Engagement Through DTF Printing

In today’s digital age, customer engagement is crucial for any business looking to thrive. DTF printing opens avenues for entrepreneurs to create highly customized products tailored to their customers’ needs. By offering personalized printing options, businesses can establish a connection with their clientele, encouraging repeat purchases and fostering brand loyalty.

Furthermore, technologies such as DTF printing can easily be integrated with e-commerce platforms, setting the stage for seamless engagement strategies. Entrepreneurs can use social media to showcase their unique designs, solicit customer feedback, and run promotional campaigns. This direct interaction not only enhances the customer experience but also positions businesses as responsive and attentive to consumer desires, which is essential in building a successful brand in a crowded market.

Frequently Asked Questions

What is DTF printing and how does it work?

Direct-to-Film (DTF) printing is a process where designs are printed onto a special transfer film, which can then be applied to fabrics using a heat press. This allows for high-quality, vibrant prints on a variety of materials, making DTF printing a flexible and efficient solution for businesses.

Is DTF printing a cost-effective printing solution for small businesses?

Yes, DTF printing is considered a cost-effective printing solution. The upfront costs for DTF printers are significantly lower than traditional methods like screen printing, with options like the LOKLiK iPrinter costing between $600 to $1,500. Additionally, material costs are relatively low, typically ranging from $0.50 to $2.00 per print.

How does DTF printing align with sustainable printing practices?

DTF printing aligns with sustainable printing practices by minimizing waste compared to conventional printing methods. The efficient use of materials and the ability to create customized prints help meet the growing consumer demand for eco-friendly products, making DTF printing an excellent choice for environmentally-conscious entrepreneurs.

What are the entrepreneurial printing solutions offered by DTF printing?

DTF printing provides entrepreneurial printing solutions that include print-on-demand services, allowing businesses to offer customized products without heavy upfront investments in inventory. This flexibility enables entrepreneurs to cater to niche markets and consumer trends effectively.

What are the revenue potential and pricing strategies for DTF printing?

Entrepreneurs using DTF printing can leverage high revenue potential by offering personalized or limited-edition items, with prices for custom pieces ranging from $20 to $50. By tapping into print-on-demand markets, businesses can also reduce costs through bulk orders while enhancing profit margins.

What type of maintenance is required for DTF printers, and is it costly?

DTF printers require regular cleaning and maintenance, but the costs are generally lower than those associated with traditional printers. Routine maintenance helps ensure consistent print quality and operational efficiency, making DTF a smart investment for small businesses.

| Key Aspect | Details |

|---|---|

| Understanding DTF Printing | DTF printing involves transferring designs from a special film to fabric, providing flexibility, speed, and high quality. |

| Sustainability | DTF printing reduces waste compared to traditional methods and aligns with the growing consumer demand for eco-friendly products. |

| Cost-Effective Equipment | Affordable DTF printers like the LOKLiK iPrinter have made high-quality printing more accessible for startups. |

| Support for Small Businesses | Compact A3 DTF printers enable small businesses to enter the market without large financial investments. |

| Cost Breakdown | DTF printing equipment costs between $600 to $1,500, significantly lower than traditional setups. |

| Revenue Potential | High profit margins are achievable through personalized items; custom pieces can sell for $20 to $50 each. |

Summary

DTF printing is revolutionizing the entrepreneurial landscape by offering a cost-effective and sustainable printing solution. As technology progresses, more entrepreneurs are turning to DTF printing for its efficiency and low waste production, essential for modern eco-conscious consumers. The availability of affordable printing equipment, alongside a supportive environment for small businesses, makes it easier than ever to enter the print-on-demand market. With DTF printing, entrepreneurs can not only minimize their operational costs but also tap into diverse revenue streams by offering personalized, high-quality products. This innovative printing method is not just an operational choice; it’s a strategic move that empowers businesses to thrive in a competitive marketplace.