DTF gangsheets have transformed the landscape of custom printing, offering designers a streamlined method to produce high-quality prints for various projects. By grouping multiple designs onto a single transfer film, DTF printing not only enhances efficiency but also optimizes resource usage, allowing for a cost-effective workflow. This approach empowers designers to maximize their creativity while ensuring that each print adheres to vibrant color management standards. In the thriving DTF printing community, sharing tips and insights on creating effective design layouts for DTF is paramount for growth and success. Whether you’re looking to perfect your gangsheets or discover essential DTF printing tips, this guide will equip you with the tools you need for impressive results.

Direct-to-Film (DTF) gangsheets, also known as multi-design transfer sheets, are revolutionizing how designers create and print custom designs. This innovative approach groups several graphics on a single film sheet, making it a favorite among professionals looking to simplify their workflow while maintaining high-quality DTF outputs. In addition to enhancing production efficiency, these sheets allow artists to showcase their skills through meticulous design layout and color management techniques. As the DTF printing landscape continues to evolve, understanding the fundamentals of creating effective gangsheets becomes essential for anyone in the custom printing industry. Whether you’re a novice or an experienced designer, mastering these concepts will lead to stunning results.

Maximizing Your Design Layout for DTF Gangsheets

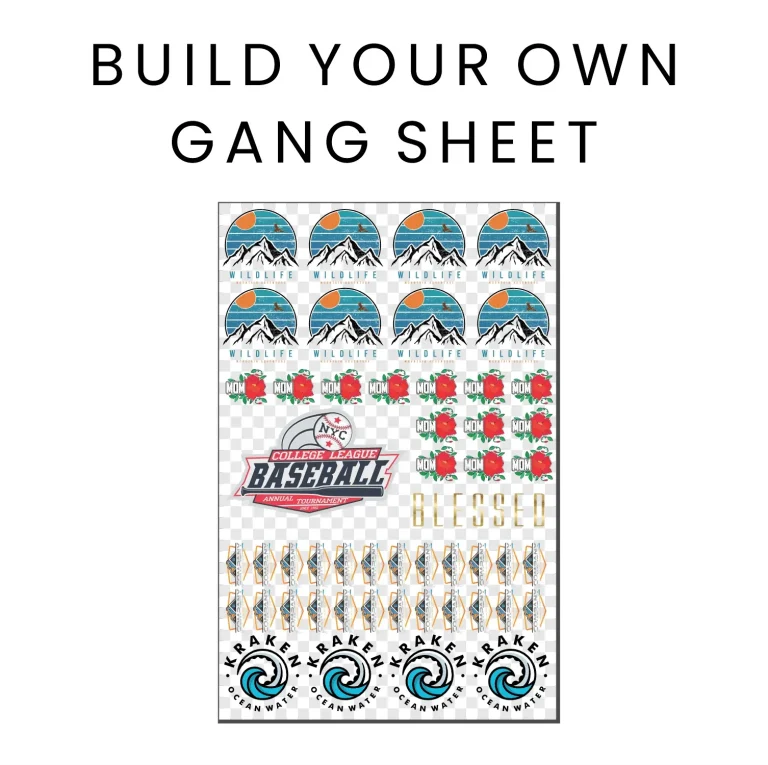

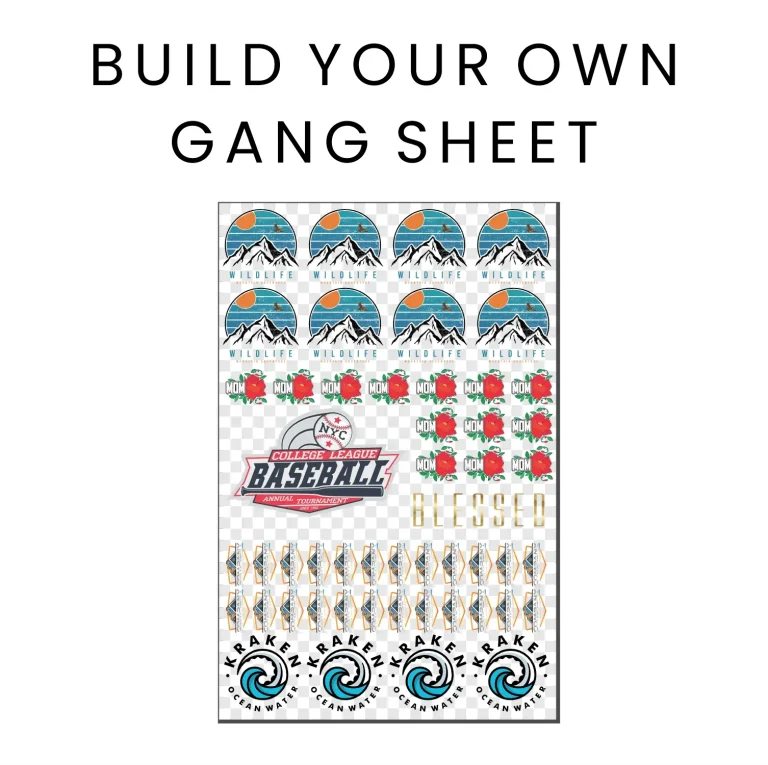

Creating effective gangsheets begins with a strategic design layout that maximizes the available space. As a designer, you should consider how different designs can be arranged to not only look aesthetically pleasing but also to streamline the printing process. By efficiently grouping your designs, you can save materials and reduce wasted transfer film, which is beneficial for both cost-cutting and environmental sustainability. Moreover, a well-planned layout helps in avoiding overlapping designs that can cause transfer issues, ensuring each printed design maintains its quality and integrity.

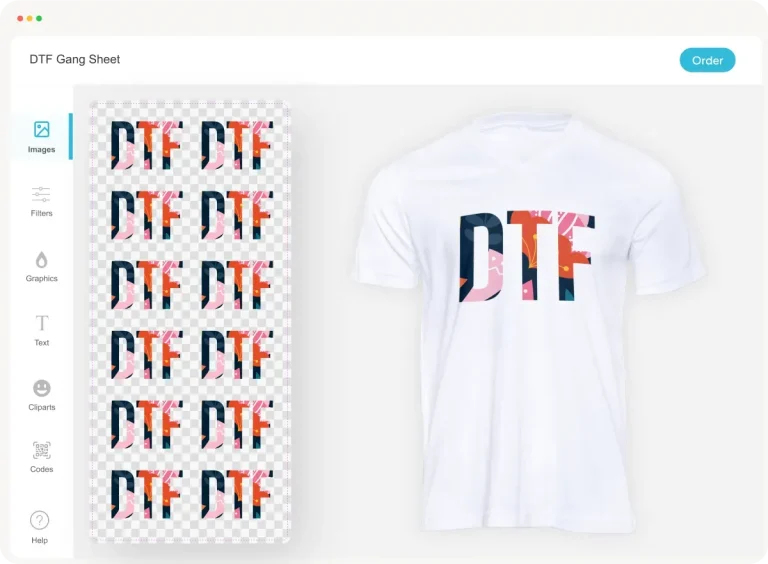

Additionally, keeping a systematic approach when arranging your layouts can significantly impact your workflow. Use software tools that offer guides and grid functionalities to assist in placing your designs accurately. This sort of precision can help you identify the optimal arrangements for various sized designs, from text to images, enhancing the overall quality of your final prints and allowing you more freedom in creative exploration.

Frequently Asked Questions

What are DTF gangsheets and how do they optimize DTF printing?

DTF gangsheets involve creating a single film sheet that includes multiple designs for Direct-to-Film (DTF) printing. By grouping designs together, you can optimize printing efficiency, reduce material waste, and save time during the printing process.

What are some design layout tips for creating effective DTF gangsheets?

To create effective DTF gangsheets, focus on maximizing the design layout by utilizing space well. Ensure there is adequate spacing between each design to prevent bleeding during the heat transfer process, which can affect print quality.

How important is color management when working with DTF gangsheets?

Color management is crucial in DTF printing. Using the correct color profiles, such as sRGB or CMYK, ensures that the colors displayed on the screens closely match the final printed output, leading to high-quality DTF prints.

What printer settings should I consider for optimal DTF gangsheets printing?

For optimal printing of DTF gangsheets, adjust your printer settings for ink density and temperature to match the requirements of the transfer film. This ensures the best adherence and clarity of the prints.

What type of film is recommended for producing high-quality DTF gangsheets?

For high-quality DTF printing, using high-quality PET films is recommended. These films are specifically designed for transferring designs effectively while maintaining excellent print quality without compromising details.

How can I engage with the DTF printing community for tips and trends about gangsheets?

Engage with the DTF printing community by following blogs, social media groups, and forums dedicated to DTF printing. Participating in these resources offers valuable tips, troubleshooting advice, and insights into the latest trends and techniques.

| Key Aspect | Description |

|---|---|

| Introduction | Overview of DTF printing and the concept of gangsheets. |

| Understanding DTF Technology | DTF printing involves printing designs onto a transfer film, which is then heat-pressed onto the substrate. |

| Creating Effective Gangsheets | Maximize space, manage colors accurately, and prepare high-resolution artwork to create effective gangsheets. |

| Printing Considerations | Adjust printer settings, choose quality film, and ensure temperature settings are correct for best results. |

| Staying Updated with Industry Trends | Engage with industry resources, follow blogs, and watch tutorials to stay abreast of DTF trends. |

| Equipment and Tools | Invest in quality DTF printers and heat presses for successful printing. |

| Community and Resources | Join online communities to share experiences and grow knowledge in DTF printing. |

Summary

DTF gangsheets are an essential tool for designers seeking to enhance their printing capabilities efficiently. By mastering the art of gangsheets, you streamline your workflow and ensure a professional outcome with vivid, high-quality prints. With effective design layouts, accurate color management, and diligent pre-press preparation, the process of creating DTF gangsheets becomes both accessible and rewarding. As you embark on this journey, remember the importance of staying updated with industry trends and engaging with a supportive community of designers. Embrace these insights to thrive in the dynamic world of DTF printing!