In the evolving realm of custom apparel printing, DTF gangsheets have quickly gained recognition as an innovative and efficient method for producing vibrant designs. By leveraging the benefits of Direct-to-Film (DTF) printing, these gangsheets enable designers and printers to transfer high-quality artwork onto various fabric types with remarkable ease. Combining intricate designs into a single layout not only streamlines production but also enhances cost-effectiveness, making DTF gangsheets a preferred choice for small businesses and custom shops. This guide delves into the art of crafting perfect DTF gangsheets using modern design builders, which play a crucial role in optimizing textile printing processes. Join us as we explore the techniques and tools that empower creators in the bustling world of custom apparel.

DTF printing, also known as Direct-to-Film printing, has revolutionized the way designers approach custom textile work, particularly through the strategic use of gangsheets. These collective sheets are created to accommodate multiple designs, enabling effective bulk printing and reducing overall material waste. The synergy between DTF print materials and advanced design builders enhances the production process, allowing for an array of unique clothing options that align with customer demands. As designers embrace this modern printing paradigm, they benefit from increased flexibility and efficiency, ensuring their custom apparel stands out in a competitive market. Exploring the mechanics behind gangsheets presents an opportunity to elevate one’s skills in the custom apparel industry.

Understanding DTF Printing: A Game Changer for Custom Apparel

Direct-to-Film (DTF) printing is revolutionizing the custom apparel industry by offering a versatile solution for printing vibrant designs directly onto fabrics. Unlike traditional printing methods, DTF printing allows for high-level detail on a variety of textile types, such as cotton and polyester blends, making it an excellent choice for t-shirts, hoodies, and promotional items. The ability to print vivid colors and intricate designs on-demand has transformed how businesses approach custom apparel production, resulting in faster turnaround times and improved customer satisfaction.

With the integration of sophisticated software, DTF printing is not just about the machinery used, but also involves understanding the materials and techniques that contribute to successful outputs. Selecting the right DTF print materials is crucial, as they impact both the aesthetics and durability of the final product. This combination of advanced printing technology and high-quality materials ensures that brands can deliver top-notch custom apparel that meets market demands.

The Critical Role of Gangsheets in DTF Printing

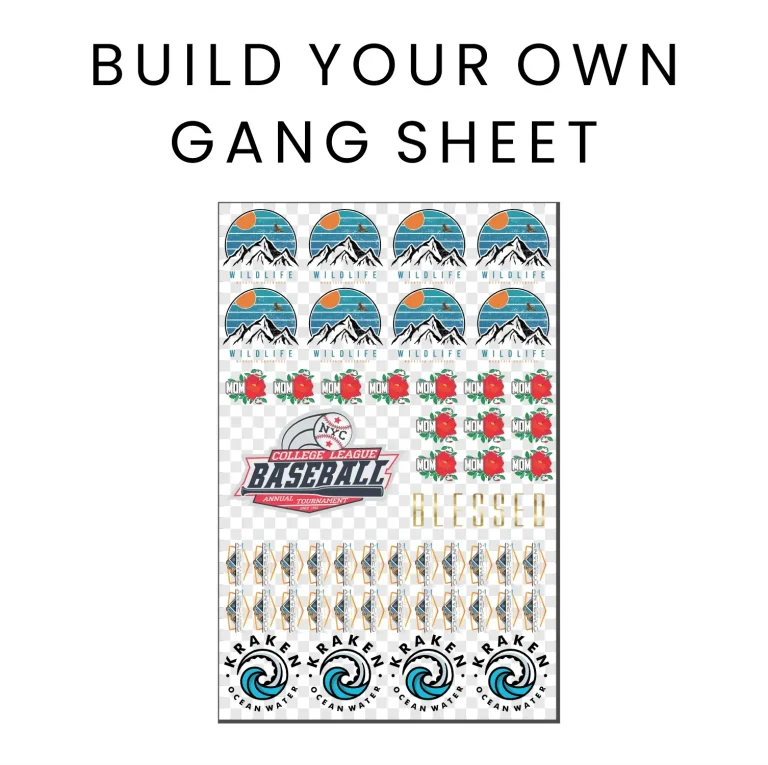

Gangsheets play a pivotal role in maximizing efficiency within the DTF printing landscape. A gangsheets allows for multiple designs to be printed simultaneously on one large sheet of transfer film, which significantly reduces production costs and material waste. This method not only streamlines the printing process, making it more cost-effective for smaller businesses, but it also enables designers to experiment and offer a wider range of options to their customers, adapting quickly to changing trends in the market.

Moreover, utilizing gangsheets enhances the workflow by allowing printers to batch process orders, thereby increasing output without compromising quality. Each gangsheet can feature a variety of designs, accommodating different customer requests on a single print run. In a competitive environment where speed and customization are key, understanding and effectively utilizing gangsheets can give businesses a significant edge.

Maximizing Efficiency: Tips for Creating DTF Gangsheets

Creating effective DTF gangsheets requires a strategic approach to design and layout. One of the essential tips for success is ensuring that all designs are properly sized and oriented to fit within the constraints of the film. Many design builders come equipped with grid systems and templates that can help in arranging your artwork systematically. Taking the time to arrange designs thoughtfully not only maximizes space utilization but also enhances the overall appearance of the final print.

Additionally, pay attention to color profiles when preparing designs for DTF printing. Bright, vibrant colors that contrast well against various backgrounds tend to yield the best results. Using high-resolution files (ideally 300 DPI or higher) is also critical to avoid pixilation issues in the final output. Remember, a well-prepped gangsheet not only enhances production efficiency but also ensures the designs are eye-catching and high-quality when transferred onto apparel.

Leveraging Design Builders for Optimal Gangsheets Creation

Design builders are invaluable tools for creating high-quality DTF gangsheets. They provide the flexibility to upload and manipulate existing artwork, allowing designers to easily create layouts that optimally utilize the printing film. Platforms like Printavo and Adobe Illustrator offer user-friendly interfaces that simplify the process of arranging multiple designs on a single sheet, enabling even novice users to produce professional-grade materials.

When using a design builder, it’s important to explore the full range of features available, such as drag-and-drop functionalities and automated resizing. These tools not only streamline the design process but also minimize the potential for error, ensuring that each element fits properly without compromising the visual integrity of the designs. By leveraging a well-equipped design builder, users can elevate their DTF printing projects to new heights, maximizing both creativity and efficiency.

Material Considerations for DTF Printing Success

The success of DTF printing heavily relies on the materials used throughout the process. High-quality transfer films and adhesives are essential for achieving prints that are not only visually appealing but also durable when washed or worn. Understanding the specifics of DTF print materials, such as ink types and film properties, can greatly enhance overall print quality, ensuring that designs maintain their vibrancy over time.

Continually staying informed about the latest advancements in DTF print materials is also crucial. Innovations in ink formulations and adhesive technologies can lead to improved transfer results and a wider range of fabric compatibility. As the industry shifts towards more sustainable practices, being knowledgeable about eco-friendly printing options can further give businesses a competitive edge, aligned with modern consumer values.

Staying Ahead in the DTF Printing Market: Trends and Resources

The DTF printing landscape is continually evolving, driven by emerging trends that can reshape how printers approach their craft. Keeping an eye on market trends such as sustainability and customization can help businesses stay relevant and appealing to their target demographics. Engaging with online resources like blogs, tutorials, and community forums can provide valuable insights and real-world tips to enhance skills and adapt to new methods.

Additionally, platforms like YouTube offer a plethora of tutorials that cover everything from the basics of using design builders to advanced techniques in handling DTF printing materials. By actively participating in the DTF printing community and embracing continuous learning, businesses can remain competitive, ensuring they not only meet but exceed the demands of today’s custom apparel market.

Frequently Asked Questions

What are DTF gangsheets and how do they work in DTF printing?

DTF gangsheets are large sheets that combine multiple designs printed simultaneously using Direct-to-Film (DTF) printing technology. This method allows for efficient production by reducing material waste and costs while enabling custom apparel brands to offer varied designs in one print run.

What are the benefits of using DTF printing for creating gangsheets?

Using DTF printing for gangsheets provides several benefits, including high-quality vibrant prints, cost efficiency due to bulk printing, flexibility in design options, and reduced waste from optimally utilizing printing materials.

How can design builders enhance the creation of DTF gangsheets?

Design builders simplify the gangsheets creation process by allowing users to easily upload designs, arrange layouts, and adjust sizes. This user-friendly approach streamlines workflow, ensuring that custom apparel printing is both efficient and effective.

What materials are best suited for DTF gangsheets in custom apparel printing?

The best materials for DTF gangsheets include specific transfer films and adhesives designed to work with DTF printing. These materials are crucial for achieving vibrant, durable prints on various fabric types, enhancing the overall quality of custom apparel.

What steps should I follow to create effective DTF gangsheets?

To create effective DTF gangsheets, select a reliable design builder, upload high-resolution designs, arrange them logically on the sheet, ensure proper spacing, and use the preview function to check alignment before printing.

How does DTF printing compare to other textile printing methods?

DTF printing stands out among other textile printing methods due to its versatility with different fabrics, ability to produce vibrant colors, and cost-effectiveness through the use of gangsheets, making it an attractive option for custom apparel manufacturers.

| Key Points | Details |

|---|---|

| What is DTF Printing? | A printing method that transfers designs onto fabrics via a special film, suitable for multiple fabric types. |

| Importance of Gangsheets | Gangsheets are layouts of multiple designs on one film, reducing costs and waste, and improving efficiency. |

| Benefits of Gangsheets | Cost efficiency, design flexibility, and reduced waste. |

| Using Design Builders | Tools for easily creating gangsheets by uploading, arranging, and resizing designs. |

| Steps to Create Gangsheets | Choose builder, upload designs, arrange layouts, adjust sizes, and preview before printing. |

| Tips for Successful Gangsheets | Consider color and resolution, stay updated with technology. |

| Educational Resources | YouTube tutorials, the Printavo blog, and community forums for skill enhancement. |

| Material Considerations | Understand inks and films that work well together for optimal printing. |

| Market Trends | Researching and adapting to market changes to stay competitive in DTF printing. |

Summary

DTF gangsheets are revolutionizing the custom apparel printing landscape by providing an efficient, cost-effective solution for creators. This innovative method allows for the simultaneous printing of multiple designs, making it easier than ever to cater to diverse customer needs while minimizing waste. Utilizing advanced design builders enables artists and print professionals to navigate the intricacies of gangsheets with ease. By optimizing materials and keeping abreast of market trends, those involved in DTF printing can elevate their craft and maintain a competitive edge in a rapidly evolving industry. Embracing these insights on DTF gangsheets will not only enhance productivity but also unlock the vibrant potential of customized textile designs.