In the rapidly expanding world of textile printing, the DTF Gangsheet Builder stands out as a game-changing tool for designers and printers alike. This innovative technology harnesses the power of Direct to Film (DTF) printing, allowing users to create intricate and colorful designs that are transferred seamlessly onto fabric. By mastering the DTF Gangsheet Builder, you not only enhance the efficiency of your printing process but also optimize your material usage, significantly lowering costs. Whether you’re producing custom apparel or intricate fabric designs, understanding the principles of gangsheet printing is essential for achieving professional-quality prints on fabric. Join us in this comprehensive guide as we explore step-by-step how to leverage the DTF Gangsheet Builder for stunning results in your textile printing projects.

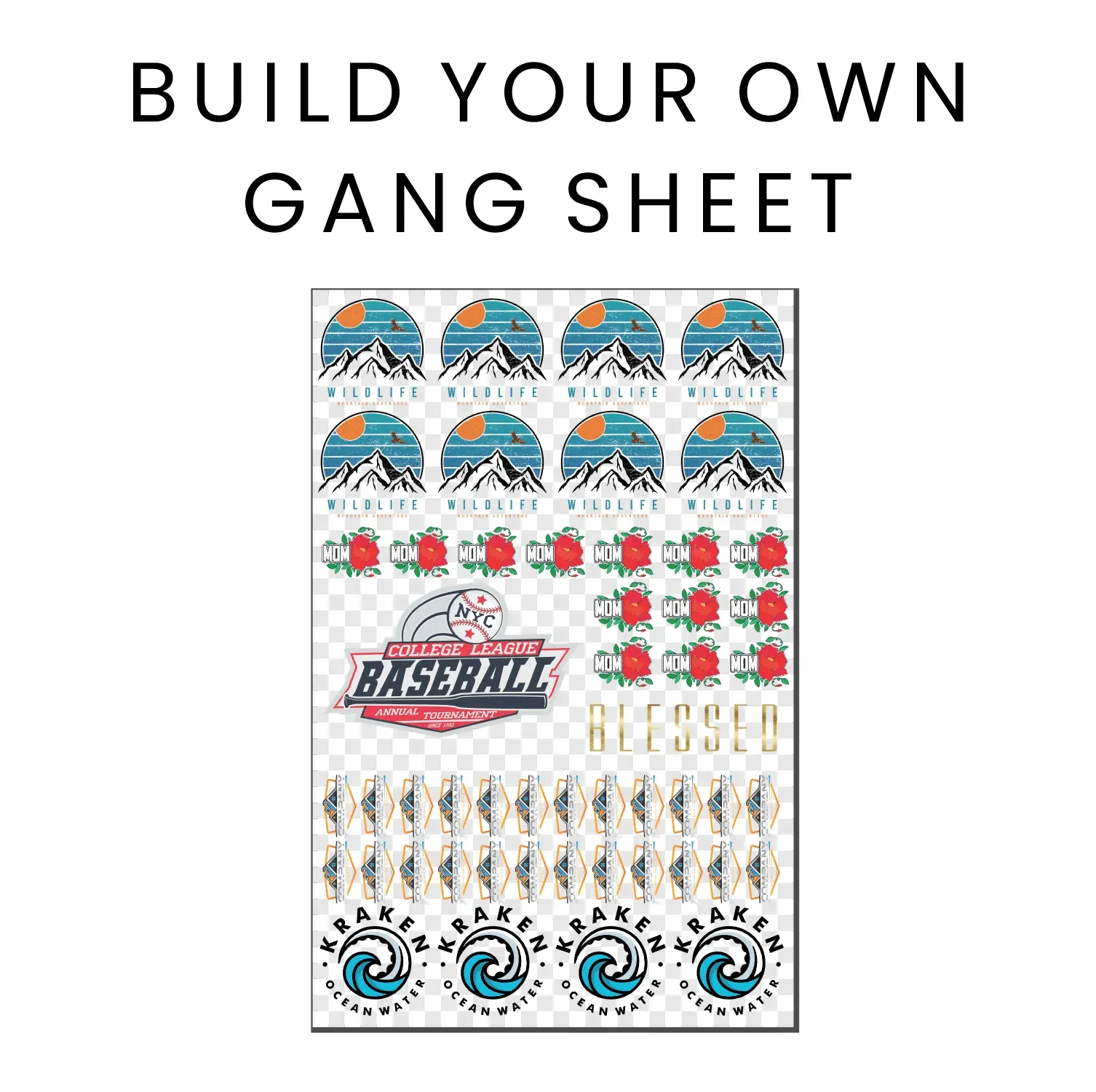

When we discuss textile printing methods, terms like DTF printing and gangsheet printing are often at the forefront. Direct to Film printing revolutionizes fabric customization by allowing digital designs to be directly applied to various textiles. The gangsheet printing technique, on the other hand, facilitates the simultaneous printing of multiple designs on a single sheet, maximizing efficiency and reducing waste. Mastering these printing techniques not only broadens your creative possibilities but also allows for a smoother workflow, making them invaluable tools in the contemporary printing landscape. Dive deeper into the intricacies of these processes, and unlock your potential in the world of fabric prints.

The Advantages of DTF Printing in Textile Industry

DTF printing brings vast benefits to the textile industry, making it a preferred choice for many print service providers. One of the most significant advantages is the ability to create vibrant, high-resolution prints on almost any fabric. Unlike traditional printing methods, DTF printing doesn’t require a lengthy setup process, which means shorter production times and reduced costs. This efficiency is especially crucial in a fast-paced market, where quick turnaround and responsiveness can be the difference between winning or losing clients.

Moreover, DTF printing is incredibly versatile. It excels in handling complex designs with multiple colors, making it ideal for custom apparel and promotional materials. The method allows for easy modifications of designs, enabling businesses to cater to diverse customer needs without incurring excessive expenses. Its eco-friendliness compared to other printing technologies further illustrates the value DTF printing brings to sustainable fashion practices.

Mastering Your DTF Gangsheet Builder for Optimized Results

To gain the maximum advantage from your DTF Gangsheet Builder, it’s essential to master its functionalities. The first step involves thoroughly understanding your software and its capabilities. This ties in with the design preparation phase, where using high-quality graphic design software ensures your templates are primed for print; colors rendered in CMYK will yield the best results. By experimenting with design sizes and arrangements within the builder, you can effectively minimize waste, streamline production, and maintain high print quality.

Once you’ve arranged your designs optimally, familiarizing yourself with the printing process itself is pivotal. Utilize the software to accurately position designs on the Gangsheet, ensuring sufficient space to avoid overlapping prints. This planning not only enhances aesthetic appeal but also helps with efficient adhesive application during the printing phase, leading to stronger bonds between ink and fabric.

Essential Tools for Successful Gangsheet Printing

In DTF printing, the right tools can significantly impact your output quality. A high-quality heat press is indispensable for transferring prints onto fabric. Choosing a press with adjustable temperature and pressure settings ensures that you can cater to various fabric types, optimizing the heat transfer process. Furthermore, having multiple sizes of DTF film allows you to handle various project scopes, from bulk retail orders to custom one-off designs.

Additionally, investing in reliable DTF inks is crucial. These inks must be compatible with your DTF system and produce vibrant colors upon transfer. Regular maintenance of your printing equipment and ensuring it is free from clogs or malfunctions will also contribute to consistently high-quality prints. Overall, incorporating these essential tools and best practices into your workflow will enhance your DTF printing experience.

Understanding Gangsheet Layout Arrangements

Effective layout arrangements on a Gangsheet are fundamental to achieving high-quality prints while maximizing material utility. By carefully placing designs, you can minimize material waste, which can often lead to significant savings, especially for large orders. Understanding the balance of spacing between prints helps manage adhesive application and prevents smudges or overlapping, which could otherwise ruin the finished product.

Additionally, it’s essential to account for design size and scale. While arranging designs, consider each garment’s dimensions intended for each transfer. This attention to detail ensures that your prints occupy the desired space on the fabric without risk of misalignment during the application, boosting the professional quality of your final products.

Tips for Effective DTF Printing

To enhance your DTF printing process, employing strategic tips can make a substantial difference. First, always perform test prints of your designs using different settings and parameters. This practice allows you to identify the optimal heat settings and transfer durations suited for specific fabric types, maximizing vibrancy and durability in the prints.

Another critical tip is to keep abreast of DTF printing communities and forums. Engaging with experts and other users online can provide invaluable insights and sharing of best practices. Learning from the experiences of others can help you overcome challenges, optimize your approach, and continually evolve your techniques to stay competitive in the dynamic textile printing market.

Future of DTF Printing Technology and Trends

The future of DTF printing technology looks promising, with rapid advancements transforming how designs are created and applied to fabrics. Innovations in ink formulations are enhancing color vibrancy and durability, while new techniques in film technology are improving ease of use and print quality. As DTF printers become more accessible, more businesses are likely to adopt this printing method, expanding its application across various sectors.

Moreover, sustainability trends are influencing the future of DTF printing. As environmental consciousness grows among consumers, manufacturers are focusing on eco-friendly inks and materials. Investing in water-based or biodegradable inks not only aligns with these trends but also appeals to a larger market segment that values sustainability. Therefore, staying updated with industry trends and technological developments will ensure that businesses remain relevant and competitive.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work in DTF printing?

The DTF Gangsheet Builder is a tool used in DTF printing to arrange multiple designs on a single film sheet, allowing for efficient production and reduced material costs. It optimizes the layout of designs, ensuring maximum ink usage while minimizing waste, which is key for successful textile printing.

How do I prepare designs for my DTF Gangsheet Builder?

To prepare designs for your DTF Gangsheet Builder, use graphic design software to create high-quality designs in CMYK color mode. Save files in suitable formats such as PNG or TIFF at a resolution of at least 300 DPI to ensure crisp prints on fabric.

What are the advantages of using Gangsheet printing with the DTF Gangsheet Builder?

Using Gangsheet printing with the DTF Gangsheet Builder greatly enhances efficiency in textile printing. It allows for multiple designs to be printed simultaneously, reducing costs for ink and materials while also speeding up the overall production process.

What steps should I follow during the layout arrangement in the DTF Gangsheet Builder?

During layout arrangement in the DTF Gangsheet Builder, ensure to utilize the proprietary software or layout tools provided with your DTF printer. Place designs strategically, allowing adequate space between them to prevent overlap, and check for proper size and alignment to guarantee professional print quality.

How do I perform the heat transfer application using the DTF Gangsheet Builder?

For heat transfer application using the DTF Gangsheet Builder, first cure your printed film with a heat press at typically 320°F for 10-15 seconds. Position the film on the prepared fabric and apply firm pressure during the heat transfer to ensure the design adheres correctly to the fabric.

What are some best practices for using the DTF Gangsheet Builder effectively?

To use the DTF Gangsheet Builder effectively, regularly maintain your DTF printer, experiment with different heat settings for various fabrics, and engage with online DTF printing communities for tips and shared experiences. This will help you stay informed and improve your printing quality.

| Key Aspect | Details |

|---|---|

| DTF Printing | A modern printing technology used for textiles, allowing high-resolution and vibrant designs to be printed on special film. |

| Gangsheet | A sheet that combines multiple designs for simultaneous printing, optimizing ink usage and minimizing costs. |

| Design Preparation | Use graphic design software to create designs in CMYK color mode and save in PNG/TIFF format at 300 DPI. |

| Layout Arrangement | Utilize DTF software to arrange designs with space between them to prevent overlap. |

| Film Printing | Print the arranged designs on DTF film and sprinkle adhesive powder on wet ink for better adhesion. |

| Heat Transfer Application | Position the cured film on fabric and heat press it at 320°F for 10-15 seconds. |

| Best Practices | Experiment with heat settings, maintain your printer, and engage with community resources for continuous improvement. |

Summary

DTF Gangsheet Builder is a vital tool for print businesses aiming for high-quality output. This step-by-step guide provides essential insights into utilizing DTF printing and Gangsheet techniques to optimize productivity and save costs. By mastering each stage, from design preparation to heat transfer application, users can create vibrant, professional fabric designs efficiently. Embracing best practices and continuous learning ensures staying competitive in the evolving landscape of textile printing.