DTF Gangsheet Builder has become the backbone of efficient garment customization, turning multi-design transfers into a streamlined workflow. This tool simplifies layout and maximizes material usage, speeding up setup without compromising color accuracy, especially in DTF printing environments. By consolidating multiple designs onto a single gang sheet, it helps shops deploy flexible print runs and maintain consistency across designs. For designers and printers, understanding the DTF transfer workflow is essential to delivering high-quality transfers on time. Embracing this technology can dramatically reduce waste and share DTF production tips for the next level.

Another way to describe this system is as a batch-design companion, turning several artworks into a single, print-ready sheet. It embraces gangsheet layouts and design consolidation to maximize fabric coverage while reducing setup interruptions. By treating the sheet as a cohesive unit, it supports scalable production planning and consistent color handling across runs. In plain terms, this approach streamlines the transfer process from concept to cloth, making large campaigns more manageable and cost-effective.

Mastering DTF Printing with the DTF Gangsheet Builder: Efficient Multi-Design Transfers

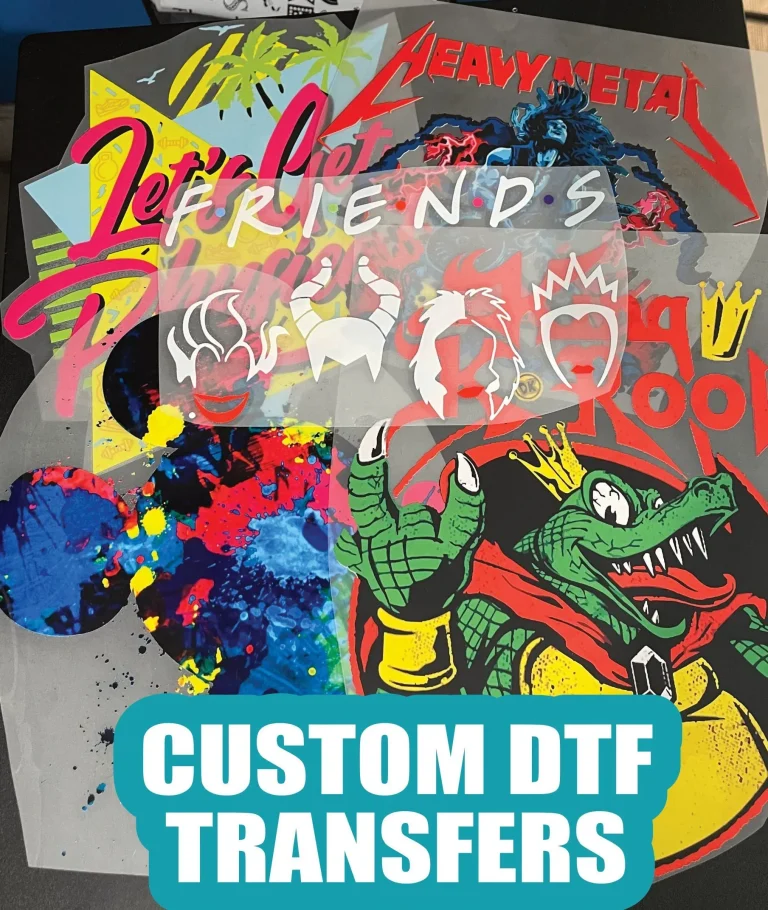

The DTF Gangsheet Builder is a dedicated tool that consolidates multiple designs into a single gang sheet, streamlining the DTF printing process and enabling more efficient production runs. By focusing on gangsheet design, you can arrange diverse artwork on one sheet, set consistent margins and bleed, and optimize color separations before sending the file to print. This approach not only accelerates output but also helps maintain uniform quality across designs, making it ideal for multi-design transfers and mixed garment runs.

In practice, using the DTF Gangsheet Builder reduces setup time and minimizes material waste by maximizing designs per sheet. The centralized layout ensures consistent transfer temperatures, alignment, and margins, which translates into tighter color control and repeatable results across batches. For shops handling varied orders, this workflow supports scalable production while preserving the integrity of each design during the DTF transfer process.

To maximize benefits, lean on best practices like standardized templates, grid-based layouts, and robust color management presets tailored for DTF printing. Incorporating these DTF production tips—such as testing small gang sheets first, documenting your workflow, and automating repetitive layouts—can further boost throughput and deliver reliable, high-quality transfers with every run.

DTF Transfer Workflow Optimization for Scalable, Consistent Production

Optimizing the DTF transfer workflow begins with thoughtful preparation: ensure designs are print-ready, properly sized for garments, and ready for color separations. A well-planned layout takes into account sheet size, garment area, and safe margins to minimize waste and reduce handling errors. By aligning these steps with the principles of multi-design transfers, you create a smooth path from digital artwork to finished garment.

From layout to press, consistency is the guiding principle. Use standardized color profiles and verified color separations to achieve faithful reproductions across all designs. The gangsheet design should emphasize balanced spacing and precise margins so that every transfer performs identically, regardless of the design variety. This disciplined approach—paired with a reliable DTF printing workflow—delivers uniform results, faster turnaround times, and cost savings on larger campaigns.

Real-world outcomes of a well-tuned DTF transfer workflow include higher production efficiency, reduced downtime, and clearer cost controls. By applying practical DTF production tips—like template-driven layouts, automated exports, and continuous monitoring of print quality—you can scale operations confidently while maintaining design integrity across hundreds of transfers.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it optimize DTF printing for multi-design transfers?

A DTF Gangsheet Builder is a specialized design and layout tool that compiles multiple designs into a single gang sheet for DTF printing. By arranging designs on one sheet, it maximizes sheet usage, reduces setup time, and helps maintain consistent color separations and transfer temperatures across multi-design transfers. It supports margins, bleed, color management presets, templates, and easy export, making the DTF transfer workflow faster and more scalable.

What features should I look for in a DTF Gangsheet Builder to optimize DTF printing and multi-design transfers within the DTF transfer workflow?

Look for drag-and-drop design placement, precise margin and bleed control, color separation presets tailored for DTF printing, templates and grids, and robust export options with embedded color profiles. Integration with common design tools and batch automation are a plus. For best results, plan layouts for scalability, maintain consistent color profiles, and run test prints to validate alignment before full production, incorporating practical DTF production tips.

| Aspect |

|---|

| What is a DTF Gangsheet Builder? |