DTF Gangsheet Builder puts powerful gang-sheet planning into your hands, turning complex layouts into a simple, repeatable process. Used with DTF gang sheets and a reliable gang sheet template, it helps teams optimize a DTF printing workflow from design to transfer. By standardizing sheet size, margins, and grid spacing, the tool delivers efficient gang sheets with precise color alignment. Its features, like grid control, automatic alignment, and export options, showcase DTF gangsheet builder features. If you’re aiming for faster production, this tool helps you cut setup time and improve accuracy across the entire run.

Viewed through an alternative lens, this kind of design tool functions as a layout engine that groups multiple artwork files onto transfer sheets. Think of it as a template-driven workflow that tightens margins, grid rules, and color planning to improve the DTF printing workflow. Using terms such as batch layout system, reusable templates, and transfer-sheet designer brings in related concepts like DTF gang sheets and efficient gang sheets while preserving clarity for readers. In practice, this approach supports faster setup, consistent placements, and scalable production in a modern print shop.

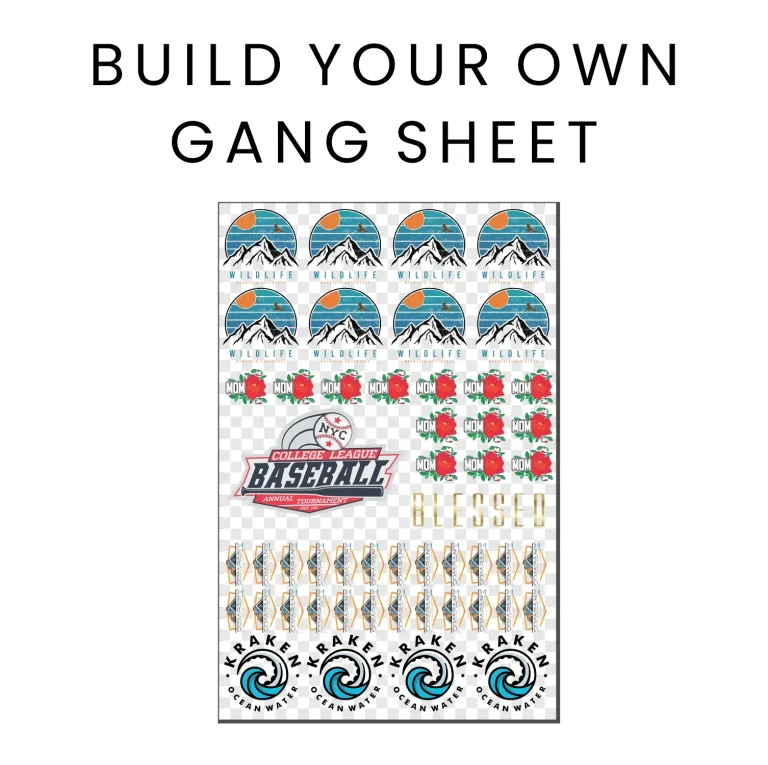

DTF Gangsheet Builder: Streamline Your DTF Printing Workflow for Efficient Gang Sheets

The DTF Gangsheet Builder is a purpose-built tool that simplifies planning, layout, and export of gang sheets. By letting you specify sheet size, safe zones, margins, and bleed, it minimizes guesswork and helps your designs print true to scale. This tight integration with your DTF printing workflow supports consistent placement and reliable color management across jobs.

With this builder, you can import multiple designs, arrange them in a grid, and preview color separations before committing to print. Snapping, alignment guides, and ink-coverage checks help prevent overlaps and color bleed, reducing waste and rework. Using the DTF gangsheet builder features—like templates, grid presets, and batch processing—makes efficient gang sheets a repeatable outcome rather than a one-off result.

Saving layouts as a gang sheet template ensures that designers can reproduce proven configurations for future jobs. Once you configure a sheet size and grid, you can save it as a template or gang sheet template to reuse across campaigns, maintaining the same safe zones and spacing. This approach supports a scalable DTF printing workflow, preserving layout consistency and color balance across orders.

Design and Export with a Gang Sheet Template: Maximize Efficiency in DTF Gang Sheets

Using a gang sheet template standardizes the building blocks of your sheets: standard sizes, safe zones, margins, gutters, and repeatable placement rules. This consistency reduces layout guesswork and speeds up every new job, especially when batch-processing multiple designs.

An effective gang sheet template also supports color-conscious planning. By aligning color counts and ink usage across designs, you minimize ink density spikes and improve color management in the DTF printing workflow. Export options—PDF, TIFF, PNG with embedded color profiles—preserve fidelity from screen to heat press and support reliable transfer results for DTF gang sheets.

Best practices for templates include maintaining a centralized asset library, using naming conventions, and reusing templates across campaigns. As you accumulate templates, you’ll realize faster throughput and consistent outcomes, demonstrating the value of the gang sheet template in delivering efficient gang sheets.

Frequently Asked Questions

How does the DTF Gangsheet Builder improve the DTF printing workflow for creating efficient gang sheets?

The DTF Gangsheet Builder standardizes sheet size, grid layouts, margins, bleed, and export settings, turning your artwork into print-ready gang sheets. By leveraging gang sheet templates and built-in alignment tools, it delivers consistent placement, reduced setup time, and better color management across runs, boosting the overall DTF printing workflow and efficiency.

What key DTF gangsheet builder features help you maximize sheet space and work with gang sheet templates?

Essential features include configurable grids and margins, snap-to-grid alignment, support for gang sheet templates, color separation preview, and template saving for reuse. Batch processing and export options further streamline the process, enabling efficient gang sheets and a scalable DTF printing workflow with reliable color and placement.

| Key Point | Explanation |

|---|---|

| What is a DTF Gangsheet Builder? | A specialized tool/workflow that configures sheet size, grid layout, margins, bleed, and export settings to align artwork for printing and transfer, reducing manual guesswork and ensuring consistent results within a DTF printing workflow. |

| What is a gang sheet? | A single transfer sheet containing multiple designs arranged in a grid or custom pattern, designed to maximize designs per sheet while preserving safe margins and color separations. |

| Purpose/Goal | To design efficient gang sheets with consistent placement, color management, and minimal setup time, integrated into a broader DTF workflow. |

| Standard sheet size & safe zones | Use standard transfer sizes (e.g., 12×18 or 16×20 inches); lock in sheet size, define safe zones to protect artwork from edge misalignment, and include bleed considerations. |

| Grid layout & spacing | Create an efficient grid with margins, gutters, columns/rows, and alignment guides; start simple (2×3 or 3×4) and scale up as needed. |

| Import & place designs | Load designs, use snapping/alignment tools, pay attention to color separations and white underlays, and note color adjustments for cohesion. |

| Color management | Ensure color counts fit printer capabilities, maintain adequate spacing to avoid bleed, and use color previews if available. |

| Export & print-ready files | Export PDFs, TIFFs, or PNGs with embedded color profiles; optionally separate color channels for control during color separation. |

| Printing workflow integration | Prepare for printing with correct color profiles, calibration, and alignment checks; optimize ink density to prevent bleed. |

| Quality control | Check for misalignment, color inconsistencies, and missing elements; use a pilot batch to verify fixes and adjust grids as needed. |

| Templates & reusability | Create reusable layouts and save templates for standard sheet sizes, margins, and grid configurations to speed future jobs. |

| Advanced tips | Standardize asset naming, build printer-specific color profiles, use batch processing if available, perform early art checks, and maintain a clear color separation strategy. |

| Common pitfalls | Watch for misalignment from margins, color bleed from tight gaps, and underutilized space; regular calibration and clear guidelines help avoid issues. |

| Bigger picture | The DTF printing workflow connects design-to-production stages, aligning upstream art validation with downstream printing, curing, and transfers for faster, more predictable outcomes. |

Summary

Conclusion: