DTF GangSheet Builder is a practical tool designed to simplify how shops plan and print multiple transfers at once. By optimizing layouts on gang sheets, it improves DTF printing efficiency and reduces material waste. This approach aligns with gang sheet production strategies that streamline production sequencing for consistency across orders. For small shops, it integrates with print shop automation, helping teams manage color, placement, and timing across batches, supporting small business printing workflows. With a focus on scalable workflows and bulk transfer techniques, it supports growing catalogs without sacrificing quality.

Viewed through a different lens, the same concept becomes a smart sheet-planning engine that groups designs on one canvas to maximize material use. This latent semantic approach ties the idea to terms like layout optimizer, print batch planner, and transfer sheet batching. In practical terms, the software acts as a production workflow assistant for designers and operators, smoothing color separations and sequencing. In short, it is a scalable solution for efficient production in small-to-medium print environments.

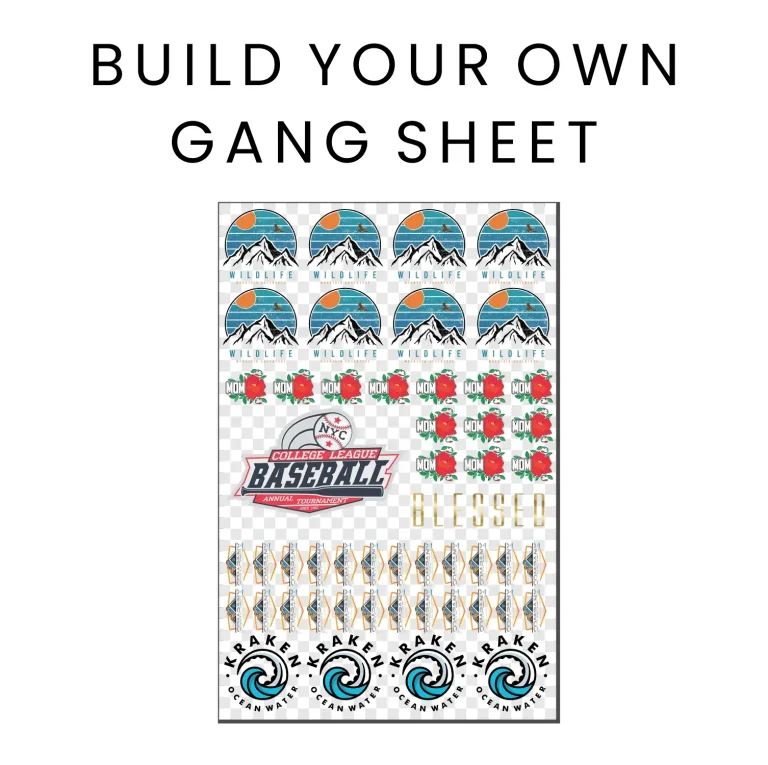

Boost DTF printing efficiency with the DTF GangSheet Builder

Using the DTF GangSheet Builder elevates DTF printing efficiency by intelligently placing designs on each sheet, maximizing surface usage and minimizing trim waste. Operators see shorter setup times because changes are driven by a single gang sheet plan rather than reconfiguring each transfer. The combination of optimized layout and color management delivers more consistent outputs across batches, which is critical when juggling multiple SKUs.

By embracing bulk transfer techniques—grouping related designs that share color counts and printing order—you can stretch each sheet further without compromising quality. This approach aligns with small business printing workflows, reducing material costs, improving forecasting, and enabling faster restocks for retailers or campaigns. The DTF GangSheet Builder acts as the engine for this scalable process, turning complex color separations into repeatable, automation-friendly sequences.

Streamline small business printing workflows with gang sheet production and print shop automation

Gang sheet production reduces bottlenecks in typical small business workflows by consolidating multiple transfers into a single print run. This approach lowers machine idle time, simplifies color separations, and aligns with print shop automation practices to deliver consistent turnarounds even when orders are volatile or seasonal.

Implementation tips include standardizing sheet sizes, templates, and color rules; training staff on preflight checks; and adopting queueing for batch jobs. This supports predictable lead times and better capacity planning, enabling faster responses to market trends while maintaining quality and margins, and reinforcing the principles of DTF printing efficiency across your operation.

Frequently Asked Questions

How does the DTF GangSheet Builder boost DTF printing efficiency for small businesses?

The DTF GangSheet Builder boosts DTF printing efficiency by automatically optimizing layout and color management to maximize material usage on gang sheets, minimizing waste and batch costs. It streamlines design placement, reducing setup time and changeovers—key components of small business printing workflows—so you can move from design to production faster. With features like deterministic layouts and easy export to printer-ready formats, it supports faster turnarounds without compromising quality, while aligning with your printer’s color capabilities to reduce reprints.

What features should you look for in a DTF GangSheet Builder to support gang sheet production and print shop automation?

Look for automatic layout optimization to maximize sheet capacity, strong design import support (AI/PSD/PNG/TIFF), and precise bleed, margins, and alignment controls. Color management integration helps prevent color drift, while export and integration options (RIP software, cutter workflows) enable smooth automation. Job batching and queueing simplify handling multiple orders, and drag-and-drop planning with reusable templates supports bulk transfer techniques by quickly assembling multiple designs on a single sheet. All of this should be accessible and affordable for a small team.

| Topic | Key Points |

|---|---|

| What is a DTF GangSheet Builder? | Software-assisted workflow that arranges several transfers on a single sheet before printing; maximizes sheet usage, reduces material waste, and streamlines the transfer process. It yields a more predictable production rhythm, faster turnaround, and better consistency across orders for shops with multiple SKUs. |

| Why small businesses need a DTF GangSheet Builder |

|

| Key features to look for in a DTF GangSheet Builder |

|

| How a DTF GangSheet Builder scales your print ops |

|

| Integrating a gang sheet workflow into your current DTF setup |

|

| Best practices for using a DTF GangSheet Builder |

|

| A practical example: scaling with gang sheets |

|

| Common challenges and how to avoid them |

|

| Conclusion | A DTF GangSheet Builder is a strategic asset for small businesses seeking to scale print operations without sacrificing quality or margins. It optimizes layout, reduces waste, and streamlines setup to enable faster turnarounds, more consistent outputs, and a more predictable production flow. When chosen and integrated thoughtfully, a gang sheet solution supports smarter decisions, helps meet demand with confidence, and positions a brand for sustainable growth in a competitive market. |

Summary

DTF GangSheet Builder is a strategic asset for small apparel businesses looking to scale printing operations without sacrificing quality. This descriptive overview highlights how it optimizes layout, reduces waste, and speeds setup, enabling predictable production, improved throughput, and sustainable growth. By integrating thoughtful workflows and best practices, the DTF GangSheet Builder helps brands meet demand with confidence while maintaining consistent quality across orders. It supports smarter decisions, smoother production rhythms, and a stronger competitive edge in the world of DTF printing.