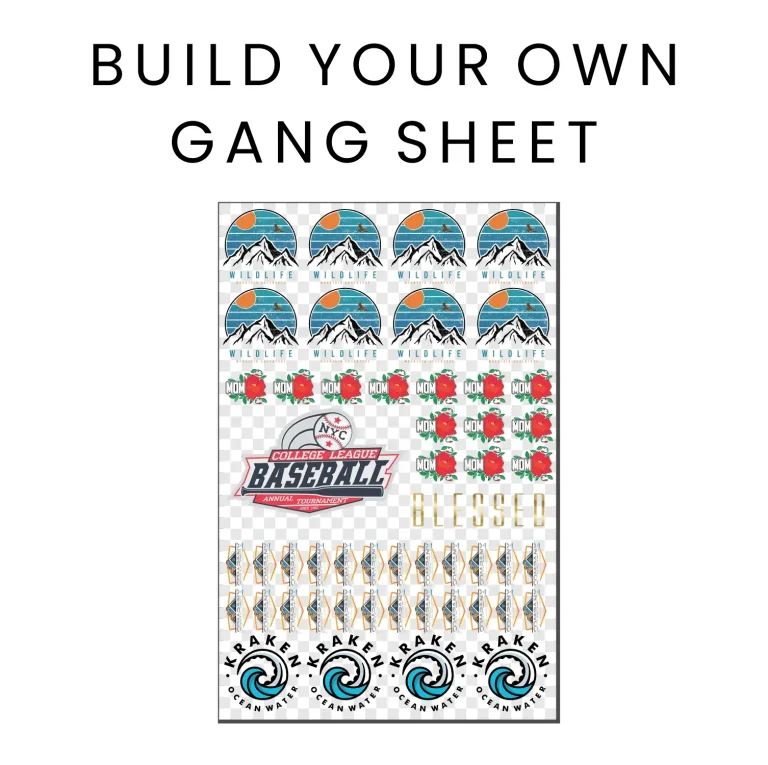

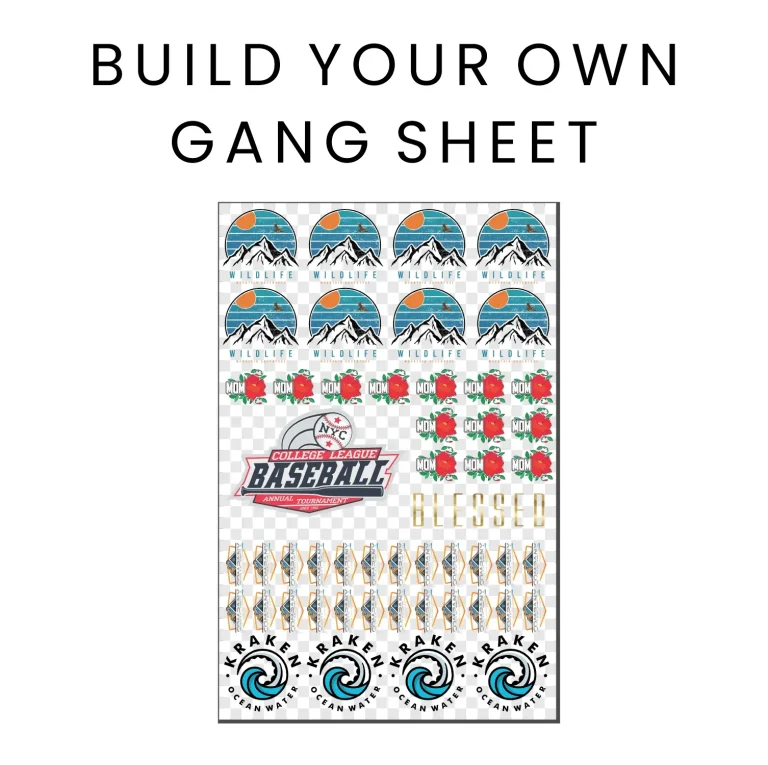

DTF gangsheet builder is changing how print shops approach garment transfers, turning complex layouts into streamlined workflows. By automating layout of multiple designs on gang sheets, it boosts efficiency, cuts waste, and speeds turnaround. These tools optimize space on each sheet, preserving color fidelity and reducing setup time across small runs and large batches. The result is a more predictable, scalable workflow that aligns design, color management, and post-processing for consistent output. Whether you print on demand or manage bulk orders, adopting a gangsheet strategy can transform profitability and customer satisfaction.

In practice, these tools act as layout optimizers for textile transfer printing, organizing several designs on a single sheet. This approach expands the footprint of each print run, reduces setup steps, and aligns color management with production scheduling. Think of it as a sheet-level planning engine for garment graphics that supports efficient ink usage and consistent results. By framing the concept with related terms, you help search engines connect the idea to broader topics like workflow efficiency and print production planning.

DTF Gangsheet Builder: Boosting Gangsheet Printing and DTF Printing Efficiency

Leverage a DTF gangsheet builder to maximize gangsheet printing efficiency by automatically arranging multiple designs on a single sheet. This approach reduces material waste, minimizes ink passes, and preserves color fidelity, ensuring consistent results across runs. By centralizing layout decisions, shops can simplify prepress and accelerate setup, delivering faster turnarounds without sacrificing print quality. The integration with your RIP and printer profile helps maintain precise margins, bleeds, and registration markers, supporting efficient DTF printing that scales with demand.

With a focused gangsheet strategy, you can expand capacity for small runs and bulk orders alike. The builder optimizes layout density while respecting fabric-specific constraints, which lowers overall production costs and improves net throughput. This streamlines gangsheet printing, enhances ink management, and reduces the need for reworks, contributing directly to print production optimization and a smoother DTF workflow across the shop.

DTF Workflow Optimization: Aligning Prepress, RIP, and Production for Print Production Optimization

An end-to-end DTF workflow optimization approach connects design intake, color management, RIP settings, and finishing into a repeatable process. When teams synchronize these stages, bottlenecks shrink, setup times drop, and color consistency improves across fabrics and inks. The result is higher DTF printing efficiency and more predictable outputs, with fewer reworks and faster fulfillment.

Key performance indicators such as waste percentage, changeover time, and throughput become actionable data. By standardizing templates, calibrating color workflows, and recording best practices, shops can iterate toward true DTF workflow optimization. Real-world results include faster prepress, improved alignment, steadier production schedules, and contributions to print production optimization, translating into stronger margins and happier customers.

Frequently Asked Questions

How can a DTF gangsheet builder boost DTF printing efficiency in gangsheet printing while reducing material waste?

A DTF gangsheet builder automatically arranges multiple designs on gang sheets with proper margins and bleeds, maximizing sheet utilization and minimizing ink passes. By consolidating jobs onto fewer gang sheets, it shortens setup times and reduces platen changes, directly improving DTF printing efficiency in gangsheet printing. Consistent color handling and reusable templates support broader print production optimization with predictable results.

What role does a DTF gangsheet builder play in DTF workflow optimization and overall print production optimization?

A DTF gangsheet builder accelerates the entire workflow by improving layout efficiency, aligning artwork with RIP settings, and reducing rework. It strengthens DTF workflow optimization by streamlining handoffs between design, prepress, and production, and by enabling measurable KPIs such as waste, changeover time, and throughput. This leads to tangible print production optimization across jobs and locations.

| Topic | Summary |

|---|---|

| What is a DTF gangsheet builder |

A DTF gangsheet builder is software that arranges multiple designs onto larger gang sheets in an optimized layout, maximizing sheet utilization while preserving margins, bleeds, color fidelity, and registration markers. |

| Why it matters for DTF printing efficiency |

Efficient gangsheet layouts reduce waste, minimize ink passes, shorten setup and changeovers, and speed color management, lowering per-unit costs and speeding order fulfillment. |

| Key benefits |

|

| The relationship between gangsheet printing and overall workflow |

Gangsheet printing is part of a broader workflow, coordinating artwork preparation, color management, RIP settings, and post-processing like curing and finishing. When paired with a robust workflow optimization strategy, it becomes a repeatable, scalable process from design submission to finished product. |

| Step-by-step setup to maximize results |

|

| Best practices for successful gangsheet printing |

|

| DTF workflow optimization: aligned processes for peak performance |

|

| Measuring success: KPIs and practical impacts |

|

| Real-world scenarios and case examples |

|

| Common challenges and how to overcome them |

|

| The future of DTF gangsheet tools |

|

Summary

DTF gangsheet builder is a pivotal tool for modern apparel printers, enabling streamlined design-to-production workflows and tangible efficiency gains. By automating layout, improving material utilization, and aligning prepress with production, shops can scale throughput, reduce waste, and deliver on-time orders with greater consistency. Embracing this technology helps transform a print shop into a more predictable, scalable operation, capable of meeting growing demand while maintaining color accuracy and quality.