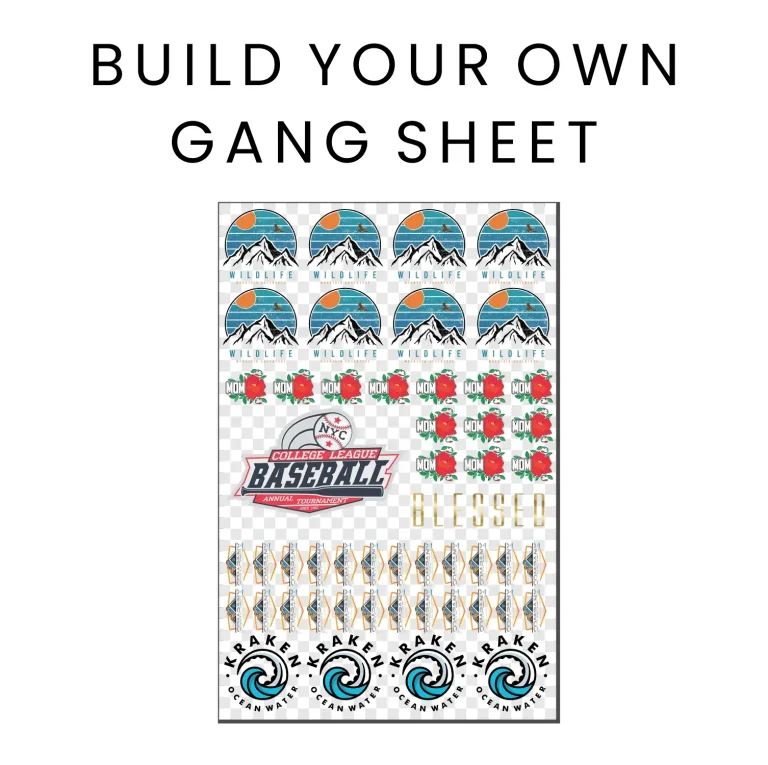

DTF gangsheet builder has emerged as a cornerstone of modern textile production, helping brands unlock more value from every yard of fabric while simplifying complex print planning for diverse collections and enabling faster onboarding of new designs. By organizing multiple designs onto a single gangsheet, it directly improves fabric utilization and reduces waste, which matters not only for cost containment but also for sustainability goals that many brands are pursuing through lean manufacturing and responsible sourcing. This optimization translates into lower material costs, faster turnarounds, and more predictable production schedules, especially when run lengths vary, designs differ in size, or you need to accommodate frequent changes in color configurations, bleed tolerance, and edge alignment. Automation handles the heavy packing work, while skilled operators can fine-tune margins, cluster similar colors, and adjust nesting layouts to maximize sheet usage without compromising print quality, and teams can reuse templates to accelerate setup across batches. With the right setup and disciplined workflows, you can extract more value from every roll and steadily improve overall DTF printing efficiency across product lines as you benchmark performance and share learnings with design studios and provide clearer, data-backed feedback that informs future design and process improvements and insights.

This approach can be thought of as a smart layout engine for fabric printing, turning a collection of designs into an efficient sheet that the printer can process with fewer passes. By considering fabric width, color blocks, margins, and tolerances, the tool reduces waste and improves material yield, aligning with principles of sheet nesting and production planning. In practice, teams use such systems to standardize templates, accelerate setup, and deliver consistent results across varying orders. The result is a more predictable workflow, tighter cost control, and a firmer foundation for sustainable textile manufacturing.

DTF gangsheet builder: maximizing fabric utilization and DTF printing efficiency

Direct-to-Fabric (DTF) printing has transformed apparel and textile production by enabling vibrant, durable prints on a wide range of fabrics. Yet fabric utilization remains a top cost driver. A DTF gangsheet builder optimizes the placement of multiple designs onto a single gangsheet, minimizing offcuts and fabric waste while respecting constraints such as print area, bleed, margins, and fabric width. This textile layout optimization not only lowers material costs but also improves DTF printing efficiency by reducing unused space and streamlining the workflow. By automating nesting and color grouping, the tool helps you squeeze more usable fabric from each roll and achieve faster throughput.

Implementing a DTF gangsheet builder involves configuring fabric width, margins, color configurations, and nesting strategy to align with your equipment. The result is a clearer path to higher fabric utilization and reduced waste, supported by a transparent waste report that tracks savings against a naïve layout. With features like auto-placement, export-ready cutter data, and integration with rip software, gangsheet optimization becomes a repeatable discipline that improves DTF printing efficiency over time. In practice, teams use templates for recurring jobs, pilot cuts for validation, and ongoing data-driven tweaks to maintain optimal textile layout optimization across batches.

Textile layout optimization for DTF printing efficiency and fabric utilization

To maximize fabric utilization, start with the basics: fabric width, roll length, and safe zones. A well-designed gangsheet layout balances size variation and orientation, often grouping designs by color ranges to minimize ink changes and washups. This approach embodies textile layout optimization and directly improves DTF printing efficiency by reducing idle space and avoidable rework.

Beyond layout, maintain standard templates for recurring jobs and track performance with waste reporting. Regularly reviewing material saved versus a naïve arrangement helps sharpen gangsheet optimization strategies and invites continuous improvement in fabric utilization. When combined with color-aware nesting and data alignment with production schedules, these practices yield more predictable yields, lower waste, and greater value for clients.

Frequently Asked Questions

How can a DTF gangsheet builder maximize fabric utilization and boost DTF printing efficiency?

A DTF gangsheet builder automatically arranges multiple designs onto a single gangsheet, minimizing offcuts and fabric waste while respecting margins, bleed, and fabric width. By optimizing layout, color groupings, and nesting strategy, it increases fabric utilization, reduces the number of sheets needed per order, and enhances DTF printing efficiency. It also exports printer-ready layouts and cutter data, supporting gangsheet optimization and seamless downstream workflows.

What practical steps does a DTF gangsheet builder offer for textile layout optimization and improving printing efficiency?

Key steps include: 1) gather designs and metadata (size, color counts, quantities); 2) configure fabric constraints (width, bleed, margins); 3) set color rules and group designs to minimize color changes; 4) choose a nesting strategy (grid, rotation allowances); 5) run auto-placement and review for fabric utilization, alignment, and workable cut paths; 6) perform manual tweaks to cluster by color and fill gaps; 7) export printer-ready layouts and cutter data, and review waste reports to monitor DTF printing efficiency.

| Aspect | Key Points | |

|---|---|---|

| Purpose | Optimizes placement of multiple designs on a single gangsheet to maximize fabric utilization and reduce waste, boosting production efficiency. | |

| What it is | Specialized software that minimizes offcuts while respecting print area, bleed, margins, color separations, and fabric width; supports design import, sizing, quantities, margins, color configurations; can export layouts or nesting data. | |

| Why fabric utilization matters | Fabric is a major cost driver; improving utilization lowers material costs, reduces waste, speeds throughput, and enables more predictable planning. | |

| Key concepts | Fabric width/roll length; Bleed and margins; Color layers and separations; Nesting strategy; Output compatibility. | |

| Getting started steps | 1) Gather designs and metadata; 2) Configure fabric constraints; 3) Set up color/print rules; 4) Choose a nesting strategy; 5) Run auto-placement and review; 6) Manual tweaks; 7) Export and integrate with production systems. | |

| Best practices | 1) Plan around fabric width and sizing; 2) Leverage color-optimized layouts; 3) Use minimal, thoughtful margins; 4) Use templates for recurring jobs; 5) Include waste reporting; 6) Do pilot cuts/prints; 7) Remember automation complements human judgment. | |

| Advanced strategies | – Multi-fold and multi-panel designs; – Dynamic sizing for on-demand variants; – Color-aware nesting with print budgets; – Cross-functional data alignment with inventory and schedules. | |

| Quick checklist | – Fabric width/length settings correct; – Bleed/margins safe zones appropriate; – Color groupings align with capabilities and costs; – Avoid overly small pieces; – Export formats compatible with printer/cutter; – Waste report available. | |

| Output and integration | Export image sheets, print-ready PDFs, and cutter vectors; generate waste reports; ensure compatibility with printers, RIP software, and cutting workflows; easy integration with production systems. | |

| Impact | Reduces waste, lowers material costs, speeds production, and improves planning accuracy by delivering efficient, cutter-ready gangsheet layouts. |

Summary

Conclusion