DTF Gangsheet Builder redefines how teams plan and execute garment projects by centralizing layouts and batch printing. It is designed to optimize every step of the DTF printing workflow, from design placement to final sheet export. The tool guides gangsheet design with precise spacing, margins, and alignment cues to maximize throughput. With support for multi-design printing, you can arrange dozens of designs on one transfer sheet without sacrificing color accuracy. Plus, built-in DTF transfer tips and heat press tips for DTF help reduce failures during transfers.

Viewed as a layout optimization platform, this solution acts as a gangsheet designer, enabling efficient grouping of artwork for common sheet sizes. By reframing the function with terms like ‘batch design planner’, ‘sheet-assembly engine’, and ‘print-ready gang sheet creator’, it signals related topics to search engines while preserving meaning. In practice, it guides users through template libraries, alignment grids, and export formats to support consistent, scalable production. This approach aligns with modern DTF workflows by connecting design assets, substrate compatibility, and press parameters into a cohesive planning tool.

DTF Gangsheet Builder: Streamlining Multi-Design Printing in Your DTF Printing Workflow

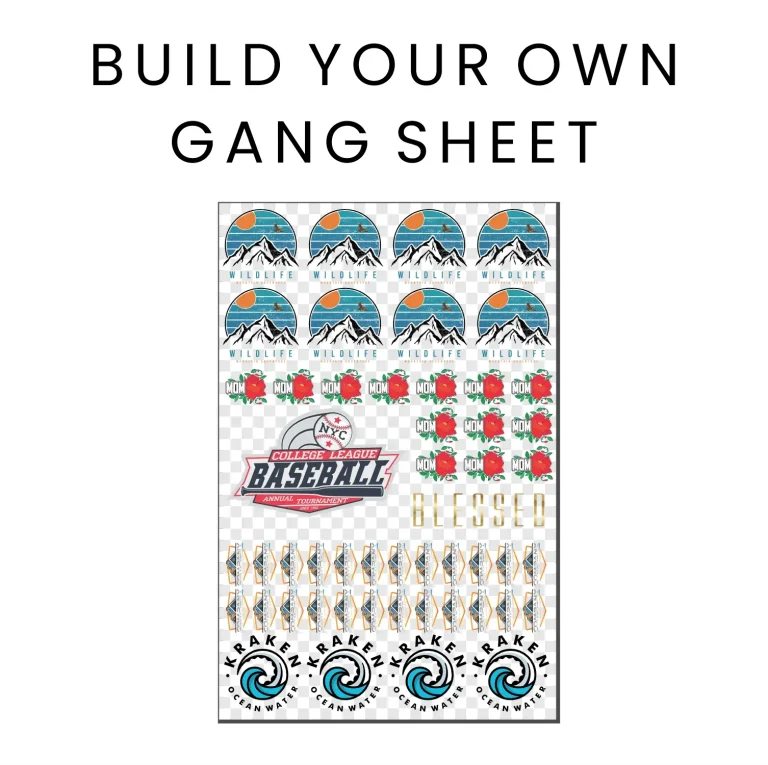

The DTF Gangsheet Builder is designed to streamline multi-design printing within the broader DTF printing workflow. By transforming a collection of artwork into a single gangsheet, it makes gangsheet design predictable—uniform margins, consistent bleeds, and aligned grids that keep every design in spec. This approach reduces waste, speeds setup, and maintains color fidelity across designs, enabling teams to scale production without sacrificing quality in the DTF printing workflow.

With templates and batch processing, you can predefine layouts for different sheet sizes, store them in a library, and rapidly assemble new collections. The builder’s alignment tools, margin guides, and bleed areas help ensure clean trimming and reliable transfer. When paired with standard export formats (PNG or TIFF) and calibrated color profiles, you gain greater predictability for DTF transfer tips and heat press tips for DTF, minimizing surprises during production.

Mastering Gangsheet Design for Efficient Multi-Design Printing and Transfer

Design placement strategies are central to a successful gangsheet, whether you opt for a uniform grid, mixed sizes, or a hybrid approach. Grid layouts provide predictability and streamline color management, while mixed-size arrangements maximize design count without compromising printable area. By prioritizing center- or high-visibility areas for color-critical designs, you can reduce rework and ensure consistent results across the DTF printing workflow.

Clear output integrity and color consistency hinge on thoughtful gangsheet design: confirm bleeds, margins, and safe zones; use consistent color profiles; and export in printer-friendly formats to preserve striping and alignment. Practical tips include maintaining a master color profile, performing pre-press checks, and running test sheets. These steps—combined with robust heat press tips for DTF and diligent DTF transfer tips—help you achieve reliable transfers and high-quality finishes across multi-design batches.

Frequently Asked Questions

How does the DTF Gangsheet Builder optimize the DTF printing workflow for multi-design printing?

The DTF Gangsheet Builder converts multiple designs into a single, well-structured layout with consistent margins, bleed, and alignment. It provides reusable templates, batch processing, and color management to produce print-ready gang sheets that align with your DTF transfer tips and heat press workflow, reducing misprints and setup time. By previewing spacing and export formats before printing, you gain predictable results across designs and batches.

What gangsheet design considerations does the DTF Gangsheet Builder address to ensure reliable color and transfer results in multi-design printing?

Key gangsheet design considerations include ensuring design compatibility with the sheet size (bleeds and safe margins), maintaining color consistency through profiles, and choosing an effective layout (uniform grid or mixed sizes) that minimizes ink use and handling. The builder’s templates support reliable export (PNG/TIF with appropriate resolution) and color management, while practical DTF transfer tips and heat press tips for DTF—such as calibrating the printer, using color targets, and standardizing transfer time, temperature, and pressure—help translate the gangsheet into consistent, high-quality transfers.

| Section | Key Points | Why It Matters |

|---|---|---|

| What is a DTF Gangsheet and why it matters | – DTF gangsheet is a sheet containing several designs laid out in a grid or packed arrangement.n- Running multiple designs on one sheet reduces material waste, trimming/handling time, and overall print cost per design.n- A well-crafted gangsheet maintains color accuracy and print quality while increasing throughput. | Improves efficiency, reduces costs, and preserves quality in high-volume production. |

| Value of using a DTF Gangsheet Builder | – Converts designs into an optimized layout with precise spacing, margins, and alignment cues.n- Consistency across designs via grid-based placement with uniform margins, bleed, and alignment.n- Faster setup with predefined templates and batch processing; shorter iteration cycles.n- Reduced misprints due to clear guidelines, cut lines, and color management.n- Clear integration with DTG/heat press workflow; exports print-ready sheets compatible with standard DTF workflows; easier color matching and heat settings. | Streamlines planning, reduces errors, and improves production predictability. |

| Key concepts in a DTF gangsheet workflow | – Design compatibility: ensure artwork fits sheet size with bleeds and margins.n- Color management: maintain color consistency using color profiles and ICC references.n- Layout strategy: grid, staggered, or hybrid layouts based on print height, width, and garment sizes.n- Output integrity: export sheets in standard formats (PNG with transparent backgrounds or TIFF); ensure print resolution matches the printer. | Guides effective planning and reliable results across designs. |

| Getting started: setting up your DTF Gangsheet Builder project | 1) Define target sheet size (e.g., A3 or larger canvas) and decide between max designs per sheet or generous margins.n2) Collect and standardize designs (consistent dimensions, transparent background where needed, and color profile aligned with printer/film).n3) Create a template library (reusable templates for different sheet sizes, margin guides, safe zones, and bleed areas).n4) Import designs into a blank gangsheet grid and use alignment tools to snap elements to grid lines.n5) Set margins and bleed (minimum margins; add bleed for edge-to-edge designs).n6) Color management: apply consistent color profiles to ensure color accuracy across designs.n7) Validate print order (optimize ink usage or pressing flow).n8) Preview to confirm spacing and alignment.n9) Export print-ready sheets in printer’s preferred format with clear batch naming.n10) Test and iterate: print a test sheet, inspect, and adjust templates or placements. | Provides a repeatable, scalable workflow for multi-design projects. |

| Design placement strategies for multi-design printing | – Uniform grid: identical dimensions and spacing; ideal for catalogs or collections with similar artwork sizes.n- Mixed sizes within a single gangsheet: flexible grid that preserves margins while packing as many designs as possible.n- Priority loading: center or accessible area for high-priority designs to minimize rewrites.n- Color blocks: group designs by dominant color to optimize ink usage and drying time. | Supports efficient layouts and faster production. |

| Practical tips to optimize your DTF printing workflow | – Maintain a clear naming convention: label files with collection, design name, and version.n- Use consistent export settings: standardize resolution (e.g., 300 dpi), color profiles, and file types.n- Plan for substrate variety: test color and shrinkage on each material and adjust templates accordingly.n- Consider production time: arrange sheets to minimize printer head movement and handling.n- Document template changes: keep a change log in the project directory. | Reduces confusion and accelerates repeatable production. |

| Techniques for reliable color and transfer results | – Calibrate printer and film setup regularly.n- Use color swatches/targets on test sheets to compare results against expectations.n- Maintain consistent heat press parameters: time, temperature, and pressure.n- Perform post-print checks for misalignment, skew, or bleed issues before pressing. | Improves color fidelity and transfer reliability across batches. |

| Common pitfalls and how to prevent them | – Overcrowding: keep safe margins to avoid quality loss and trimming issues.n- Misalignment due to inconsistent grids: use snapping and alignment guides.n- Color mismatch across batches: maintain a master color profile and re-check when switching printer/film.n- Poor trim lines: include clear cut lines or safe zones in templates. | Prevents quality drops and costly reworks in production. |

| Real-world workflow example: launching a 20-design collection | Imagine launching a 20-design t-shirt collection by grouping designs into four blocks of five on a single 12 x 18 inch gangsheet with 0.25 inch bleed and 0.5 inch margins. Place five designs per sheet and align color profiles with the printer/film. After test prints, adjust color management, re-export, and run additional tests to achieve consistent, vivid prints across all 20 designs when printed in batches. This approach reduces setup time, waste, and speeds up production. | Illustrates the efficiency and quality gains of a well-planned gangsheet workflow. |

| Maintenance, organization, and scalability for long-term use | – Organize project structure: templates, design exports, and an archive for completed gang sheets.n- Version control: timestamped or versioned iterations.n- Backups: regular backups of templates, assets, and exports.n- Reuse templates: library for common sheet sizes and layouts.n- Documentation: keep a simple guide for color profiles, margins, and bleed settings. | Supports sustainable, scalable operations and knowledge transfer. |

| FAQ: common questions about using a DTF Gangsheet Builder | Q: Is a gangsheet approach suitable for all printers?nA: Most modern DTF printers support gangsheet layouts; confirm printable area, margins, and color management for your model and film type.nnQ: How do I ensure color accuracy across designs?nA: Use consistent color profiles, calibrate your printer regularly, and test with color targets on sample sheets before full runs.nnQ: What about designs with different sizes?nA: Use flexible grid layouts that accommodate varying dimensions while preserving margins and alignment. Group designs with similar sizes when possible to simplify layout.nnQ: How can I speed up production without sacrificing quality?nA: Pre-built templates, batch processing, and standardized export settings help maintain quality while reducing setup time for each sheet. | Addresses common concerns and optimizes adoption. |

Summary

HTML table describing the key points and workflow of a DTF Gangsheet Builder-based system.