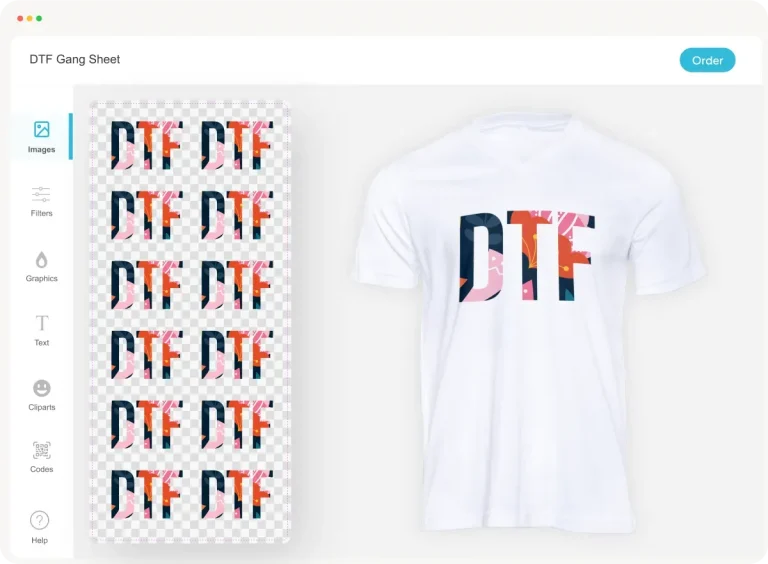

DTF gangsheet builder is reshaping how teams approach bulk orders in direct-to-film printing by turning scattered designs into a single, production-ready sheet. For bulk orders DTF printing, consolidating designs into one layout reduces setup time and minimizes misprints across the run. This supports DTF gang sheets optimization by maximizing nozzle utilization and standardizing color management across designs. If you’re wondering how to create DTF gang sheets, the builder guides layout decisions, spacing, safe zones, and alignment marks. The result is improved DTF printing efficiency for bulk orders, lowering costs while maintaining consistent transfer quality.

Beyond the tool itself, practitioners describe batch-ready transfer planning, where multiple designs are grouped into a single sheet to streamline production. This mindset relies on sheet consolidation, layout automation, and standardized color handling to boost efficiency on high-volume runs. By thinking in terms of integrated design sets, manufacturers can reduce changeovers and improve consistency across garments. Latent Semantic Indexing (LSI) principles guide this approach by using related terms such as multi-design transfers, production-ready gang sheets, and template-based workflows to strengthen topical relevance.

DTF Gangsheet Builder: Maximizing Efficiency for Bulk Orders

In the world of direct-to-film (DTF) printing, a DTF gangsheet builder is a strategic asset for bulk orders. By consolidating multiple designs into a single gang sheet, it helps maximize printer nozzle usage, reduce setup time, and ensure consistent results across large runs. This approach supports DTF gang sheets optimization by reducing the number of print runs and streamlining pre-press preparations, which translates into faster production and fewer misprints during bulk orders.

The core value of a gangsheet builder lies in centralized layout control and color management. When all designs share a unified color space and spacing rules, you achieve uniform transfers across thousands of garments. This consistency is especially critical for bulk orders where small variations can compound into a quality and timing problem. As a result, you gain improved printing efficiency for bulk orders, lower per-item costs, and a clearer path to scalable production.

Beyond layout, many builders offer features like registration marks, automatic bleed, and output presets that align with your printer’s capabilities. By pre-planning sheet dimensions, you can optimize nozzle usage and minimize waste, while maintaining safe zones for garment placement. In practice, this means shorter setup times, fewer reprints, and a more predictable workflow when handling large quantities of designs.

How to Create DTF Gang Sheets for Scalable Production and Cost Savings

If you’re new to the concept, knowing how to create DTF gang sheets starts with a solid intake and standardization process. Gather all artwork, fonts, and color specs and then map them to your printer’s printable area. A well-structured workflow makes it easier to scale from a handful of designs to hundreds, while maintaining color fidelity and alignment across all items.

For practical execution, the how-to involves layout optimization, central color management, and clear cutting considerations. You can follow a routine: define default sheet size, arrange designs to maximize transfers per sheet, apply a consistent color profile, and generate necessary cut lines or registration marks. This approach supports bulk orders DTF printing by boosting efficiency, reducing waste, and ensuring that every transfer sheet is press-ready for fast, repeatable production.

To reinforce success, pilots and tests are essential. Run a small batch to verify color accuracy, alignment, and transfer quality before committing to a full bulk run. Standardizing on templates and documenting placement guidelines helps teams reproduce exact results across large catalogs, thus enhancing DTF printing efficiency for bulk orders and making future mass productions even more predictable.

Frequently Asked Questions

How does a DTF gangsheet builder boost DTF printing efficiency for bulk orders?

A DTF gangsheet builder consolidates multiple designs into a single gang sheet, reducing setup times and print runs. It guides layout to maximize transfers per sheet, supports DTF gang sheets optimization for consistency across bulk orders, centralizes color management to keep colors uniform, minimizes waste, and streamlines inventory planning—boosting DTF printing efficiency for bulk orders.

What are the essential steps on how to create DTF gang sheets using a DTF gangsheet builder for bulk orders?

Key steps include: 1) design intake and standardization to ensure compatible artwork; 2) layout optimization to fit as many transfers as possible within printer limits; 3) color management and separation for consistent transfers; 4) adding registration marks or cut lines for accurate placement; 5) output and file preparation with proper bleed, margins, and formats for your printer. Following these steps helps with bulk orders by maintaining quality and reducing misprints.

| Aspect | Key Points |

|---|---|

| What is a DTF gangsheet builder? | Software/workflow that compiles multiple designs into a single gang sheet for DTF printing; handles layout, color management, and preparation for transfer. |

| Benefits for bulk orders | Speeds production; ensures consistent color and placement; reduces waste; aids inventory management; improves profitability. |

| How it works in practice | Design intake and standardization; Layout optimization; Color management and separations; Registration and cutting considerations; Output/file preparation. |

| Key features to look for | Automatic layout optimization; Flexible grid and alignment controls; Central color management; Output formats/presets; Print-ready infrastructure; Scalability. |

| Practical tips | Design with future batches in mind; Standardize on a sheet size/template; Use safe zones; Validate with a test batch; Monitor waste/yield; Leverage automation where possible. |

| Case study | Example: 1,000 shirts with 20 designs; grouped into a few gang sheets; reduced production time; fewer misprints; 12–15% transfer material waste saved; deadlines met. |

| Common challenges | Color matching; Garment variability; Complex artwork with fine detail; Printer limitations (rotation/width). |

| Workflow integration | Design hub; Layout stage; Color management; Printing; Pressing; Reporting. |

| Bottom line | Centralizing and optimizing gang sheets reduces setup time, waste, and costs; enables faster, scalable bulk production. |

Summary

DTF gangsheet builder transforms bulk-order workflows in DTF printing by planning, arranging, and executing large transfers with precision. It emphasizes layout optimization, color consistency, and print-ready output to cut production time and material waste while maintaining quality. For businesses handling large orders, adopting a gangsheet approach improves predictability, efficiency, and profitability, enabling faster turnaround and scalable growth.