DTF GangSheet Builder reshapes how brands move from concept to transfer, letting teams lay out multiple designs on a single sheet with precision, while providing a guided workflow that reduces misplacements and supports scalable template creation for future campaigns. In the fast-paced world of garment printing, this tool aligns with the broader design to print workflow by consolidating files, enforcing consistent color vectors, and enabling smoother production across in-house teams and external partners. By automating tiling, color management, and bleed planning, it supports DTF printing, gang sheet design, and bulk garment printing with reduced setup waste, and provides real-time feedback on spacing and bleed margins to help operators catch issues earlier. Users gain faster turnarounds, improved color fidelity, and more consistent results across runs, turning scattered assets into production-ready gang sheets, while the result is a repeatable process that lowers training time and reduces back-and-forth revisions during prepress. If you’re scaling operations, cutting setup times, and sustaining quality, this gang-sheet tool is worth evaluating for your print shop, as it integrates with existing software stacks, supports a range of output formats, and invites feedback from design and production teams to refine templates.

Seen from another angle, this approach functions as a tile-based layout engine that converts a batch of artwork into a production-ready sheet optimized for film transfer. LSI-friendly terminology would call it a gang sheet creator or batch-layout utility, designed to streamline prepress, preserve color relationships, and minimize misprints. In practice, it complements the broader printing automation and bulk garment printing workflows by reducing manual rearrangement and ensuring consistent margins across designs. Ultimately, adopting such a tool supports a scalable design-to-print pipeline, enabling faster product launches while keeping quality and efficiency in check.

[DTF GangSheet Builder] for Smarter DTF Printing: Streamlining the Design-to-Print Workflow

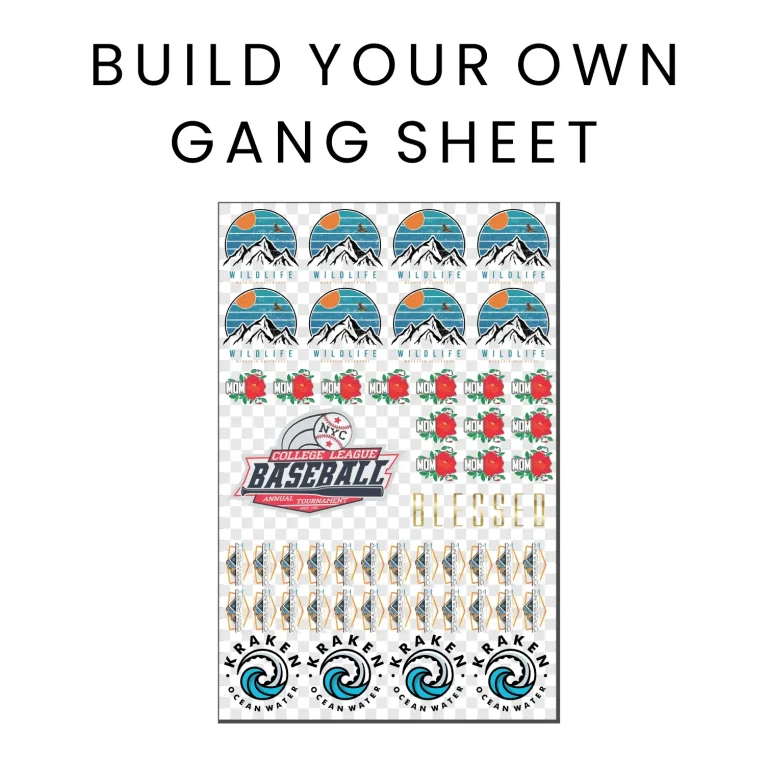

A DTF GangSheet Builder automatically tiles multiple designs onto a single gang sheet, preserving color accuracy, bleeds, and alignment. This approach reduces the number of separate prints and setup time, aligning with the broader design to print workflow. By automating tiling and spacing, you enable printing automation that moves from file export to production with minimal manual tweaks, which is ideal for teams handling rapid releases in DTF printing.

Beyond speed, the tool improves material utilization and color consistency across designs. The gang sheet design consolidates assets, lowers film waste, and simplifies file management, making it easier to scale for bulk garment printing. With templates and batch processing, you can maintain repeatable results as product catalogs grow, ensuring predictability in print quality and production schedules.

Design to Print Workflow Excellence: Leveraging Gang Sheet Design for Efficient Production

From planning to export, the design to print workflow benefits from consistent asset specs, color profiles, and automated layout rules. A strong gang sheet design supports this by standardizing margins, bleeds, and tile alignment, so RIPs ingest layouts without extra conversion. When you pair standardized export formats with color-managed pipelines, you preserve color fidelity across batches and reduce rework.

In bulk garment printing scenarios, streamlined workflows translate into faster launches and lower cost per unit. Printing automation reduces manual steps and human error, while a well-designed gang sheet layout helps you maximize sheet utilization, minimize waste, and keep production on schedule. This combination makes it easier to scale operations, meet tight deadlines, and deliver consistent results across large runs.

Frequently Asked Questions

How can the DTF GangSheet Builder optimize the design to print workflow for bulk garment printing?

The DTF GangSheet Builder automatically tiles multiple designs into a single gang sheet optimized for DTF printing, preserving color accuracy, bleeds, and alignment. It reduces setup time, minimizes misprints, and improves material utilization, aligning with the design to print workflow. For bulk garment printing, this translates to faster production, scalable templates, and more consistent results.

What features make the DTF GangSheet Builder effective for gang sheet design and printing automation in DTF printing?

Key features include automated tiling and spacing, color management and separation, bleed and margin handling, export formats compatible with RIP software, and batch processing with templates. These capabilities streamline the printing automation process, cut prep time, improve color consistency, and support bulk garment printing with scalable layouts.

| Topic | Key Points | Why It Matters | Notes |

|---|---|---|---|

| Introduction |

|

Sets the stage for why gang sheets add value in production and help streamline the workflow. | Provides context for the rest of the points in the table. |

| What is a DTF GangSheet Builder? |

|

Reduces manual work and speeds up the path from design to print. | |

| Why gang sheets matter in DTF printing |

|

Direct impact on efficiency, material use, and production throughput. | |

| Key features you’ll typically rely on |

|

Delivers consistent, production-ready outputs compatible with common RIPs and workflows. | |

| Real-world benefits you can count on |

|

Translates tool features into tangible business gains. | |

| How to get the most from a DTF GangSheet Builder |

|

Guidelines to maximize accuracy and efficiency. | |

| Advanced tips for optimizing a DTF workflow |

|

Best practices for high-stakes production. | |

| Case study snapshot: a mid-sized apparel brand |

|

Real-world impact and metrics. | |

| Implementation checklist |

|

Practical steps for rollout and continuous improvement. |

Summary

[This section contains an HTML table that summarizes the key points from the base content (Introduction to DTF GangSheet Builder and related sections) in English.]