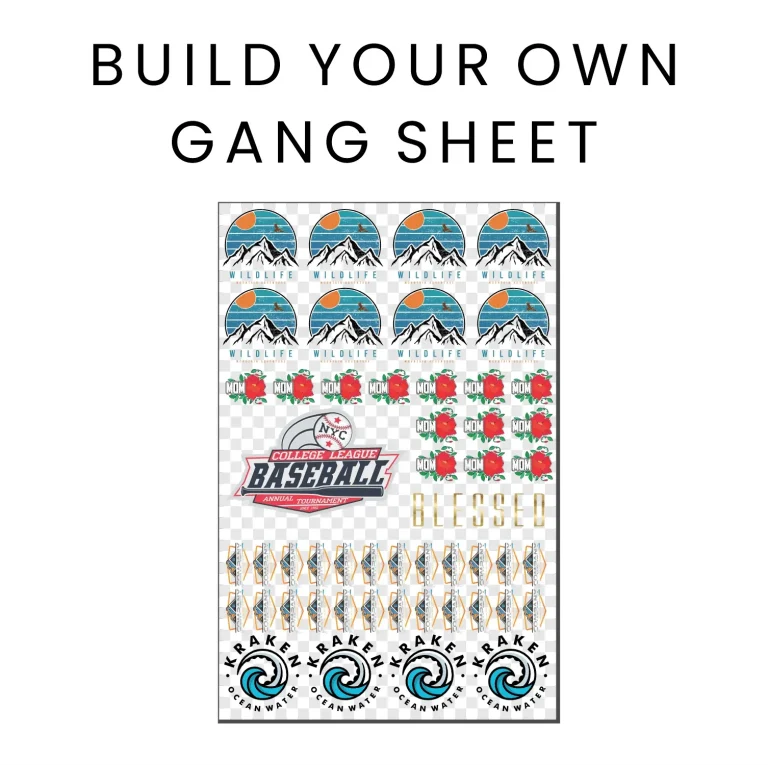

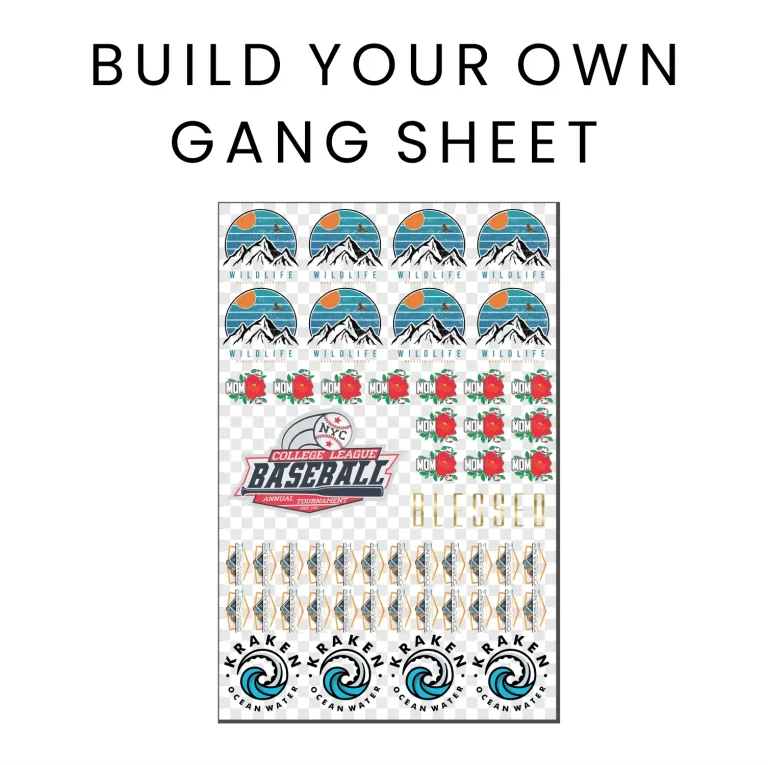

DTF gangsheet builder is transforming how apparel brands manage multi-design production, turning scattered artwork into organized, print-ready batches. By automatically nesting designs on gang sheets, calculating margins, and generating print-ready files, this tool speeds setup and reduces errors. It integrates with DTF batch printing software workflows, enabling scalable production while preserving color integrity and consistency. Look for DTF gangsheet builder features such as drag-and-drop layout, auto-nesting, margin and bleed control, and preflight checks that align with DTF layout tool for batch printing. Equipped with a DTF gang sheet generator mindset and strong print optimization, the system maximizes throughput, minimizes waste, and improves predictability across jobs.

In other terms, this technology acts as a batch-layout engine, grouping multiple designs on a single printable sheet to maximize material use. By treating a sheet as a canvas that can accommodate many designs, brands can reduce setup time and lower per-item costs. From a workflow perspective, the approach supports efficient asset management, consistent color rendition, and streamlined prepress preparation across catalogs. Guided by LSI principles, this approach links related ideas—layout automation, nesting efficiency, color management, proofing, and export readiness—to help search engines connect your content with the broader DTF production ecosystem. Ultimately, adopting this mindset aligns with how modern manufacturing platforms optimize batch output, repeatability, and scalability through structured templates and intelligent validation.

DTF gangsheet builder: Accelerate Batch Printing, Reduce Waste, and Scale Production

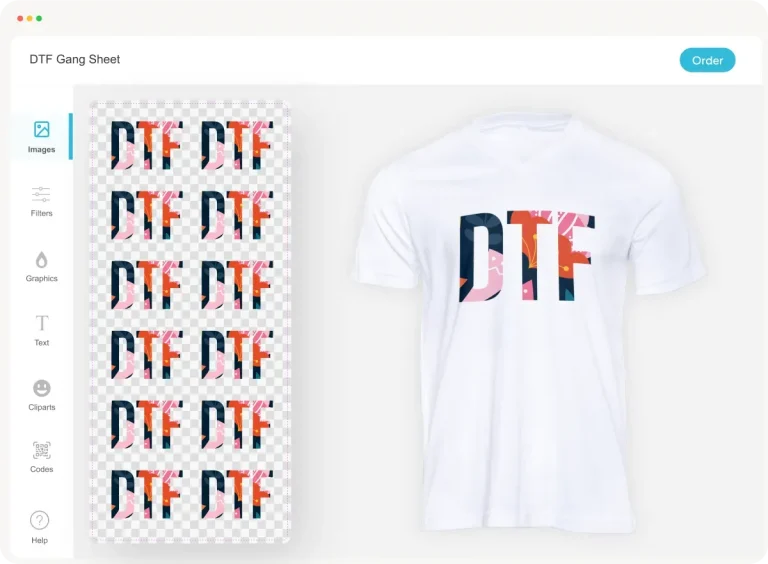

A DTF gangsheet builder automates the core task that often bottlenecks production: laying out multiple designs on a single sheet. By handling auto-nesting, margin and bleed control, and color management, this tool streamlines setup, shortens changeovers, and ensures each gang sheet prints accurately. When you leverage DTF gangsheet builder features like template presets and preflight checks, you gain faster job preparation and more reliable results, which directly supports increased throughput and lower waste.

This technology connects tightly with DTF batch printing software and other production workflows. The occasional need to adjust color profiles or reflow artwork is minimized because the system maps assets to the sheet with precision, producing print-ready outputs that align with RIP settings. As a result, you benefit from improved DTF print optimization, a steadier production cadence, and a scalable process that supports expanding catalogs and more variant configurations, powered by a reliable DTF gang sheet generator.

DTF layout tool for batch printing: Key Features, Best Practices, and Quality Outcomes

A robust DTF layout tool for batch printing offers drag-and-drop layout, automatic nesting, and broad design import support to preserve artwork integrity across multiple designs. By focusing on margin, bleed control, and consistent color management, these tools reduce setup time and minimize errors, enabling operators to run larger batches with confidence. Template and batch presets further boost consistency, so repeated jobs maintain the same layout logic and color fidelity.

To maximize impact, integrate the DTF layout tool with your broader batch printing workflow and the DTF batch printing software you already use. The combination of auto-nesting, preflight checks, and printer-ready exports supports continuous improvement in DTF print optimization. In practice, you’ll also encounter the concepts of a DTF gang sheet generator working in tandem with a dedicated layout tool, culminating in faster production cycles, fewer misprints, and a smoother path from asset intake to finished batch runs.

Frequently Asked Questions

How does a DTF gangsheet builder improve batch printing efficiency in the DTF workflow?

A DTF gangsheet builder automates design placement on gang sheets, enabling true batch printing efficiency. With auto-nesting, it maximizes sheet utilization and reduces manual adjustments. It generates print-ready files with correct bleed, margins, and color profiles, ensuring RIP-ready output. When integrated with DTF batch printing software, it also supports queue management and quick reprints, reducing setup time, labor cost, and material waste while improving color consistency and overall DTF print optimization.

What features should I look for in a DTF gang sheet generator or layout tool for batch printing to maximize throughput?

Key features include drag-and-drop layout with auto-nesting, broad design import support (AI, EPS, SVG, PNG, TIFF), precise margin and bleed control, robust color management with ICC profiles, and preflight checks. Also look for templates and batch presets, queue management, and seamless export to printer-ready formats, plus integration with your DTF batch printing software to streamline workflows.

| Topic | Key Points |

|---|---|

| What it is and why it matters | – A gangsheet is a single printable sheet containing multiple designs arranged in a grid, optimizing material usage and machine time. – A DTF gangsheet builder reads design files, nests/maps designs on a grid, and outputs a print-ready file with correct bleed, margins, and color profiles. – Benefits include faster setup, fewer misprints, and a more predictable production schedule. |

| Key Benefits | – Increased production speed: Batch more designs per print run, reducing idle machine time. – Material efficiency: Optimize placement to minimize waste and substrate usage. – Consistent color quality: Apply uniform color profiles and preflight checks across the gang sheet. – Lower labor costs: Automate layout and reduce manual setup for each job. – Better proofing: Visualize layouts before printing to catch issues early. |

| Core Features to Look For | – Drag-and-drop layout and auto-nesting – Design import and format support (AI, EPS, SVG, PNG, TIFF) – Margin and bleed control – Print-ready outputs and color management – Template and batch presets – Queue management and batch scheduling – Integration with production workflows – Preflight checks and error reporting |

| How to Use: Practical Workflow | 1) Gather designs/assets; 2) Define sheet parameters; 3) Import designs and map positions; 4) Apply color management; 5) Create templates; 6) Preflight and validation; 7) Export to print-ready files; 8) Test print and adjust; 9) Schedule and print. |

| Best Practices | – Plan using data-driven templates – Standardize color management – Calibrate printers and media – Use proofs and swatches – Maintain a change-log – Optimize for waste reduction – Train operators |

| Common Challenges | – Overcrowded sheets: rebalance layouts to prioritize critical sizes and even ink coverage. – Color drift between runs: use standardized color profiles and calibrate regularly. – File format compatibility: maintain a standard set of formats; use reliable converters when needed. – UI complexity: choose tools with intuitive interfaces, clear previews, and helpful error messages. |

| Case Study | A small apparel brand adopted a DTF gangsheet builder to manage a growing catalog. They moved from printing designs individually to using reusable templates, cutting setup time by 40% and reducing material waste by 15%, enabling faster design iteration and more frequent product drops. |

| Troubleshooting Quick Tips | – If outputs look faded, check the color profile and calibrate. – If designs shift, verify margins, bleed, and sheet alignment; re-run with corrected settings. – For missing assets, maintain a centralized asset library and enforce license checks during preflight. |

Summary

Conclusion