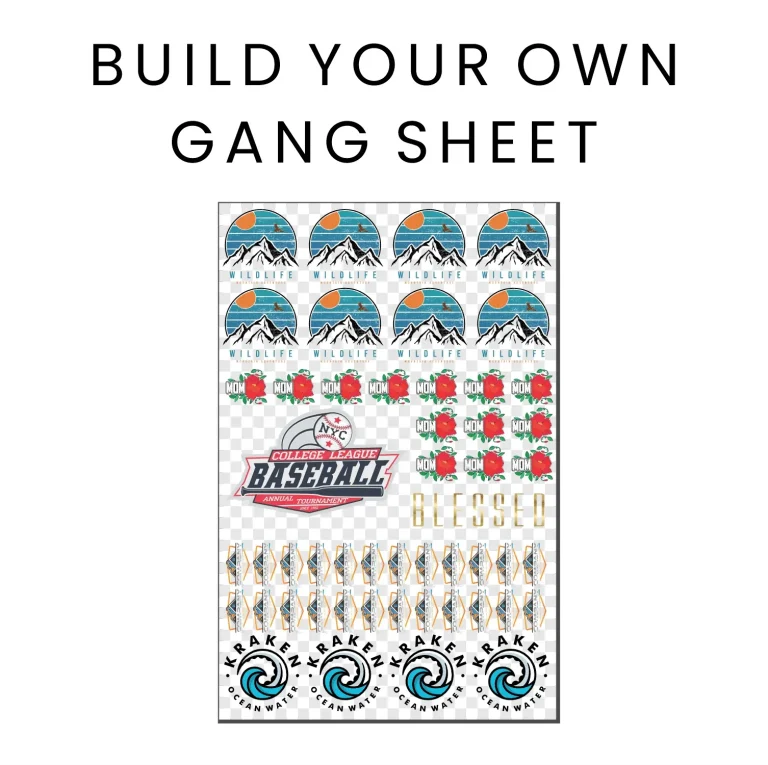

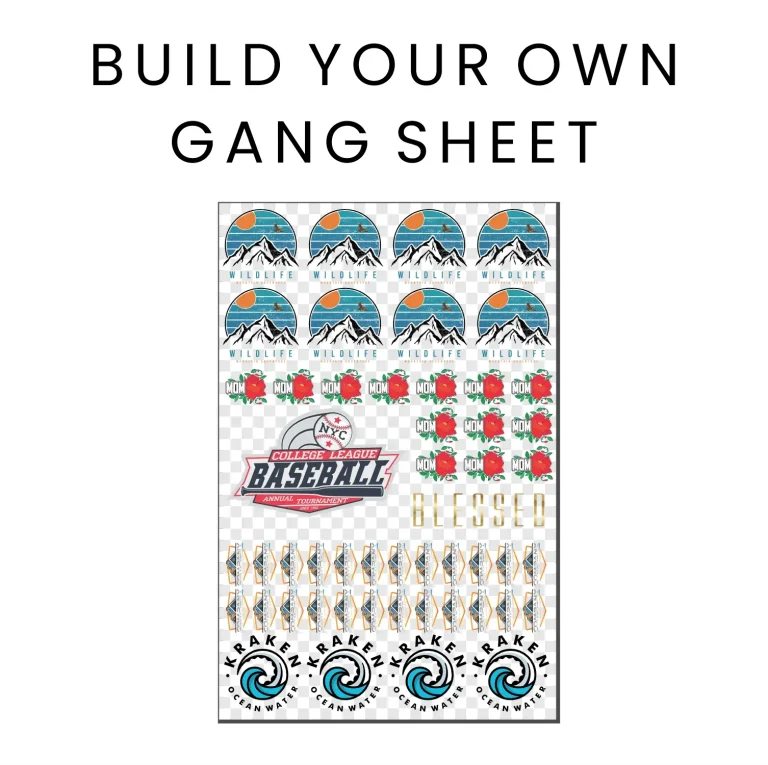

In today’s fast-paced printing business landscape, the DTF Gangsheet Builder stands out as a game-changing innovation. This revolutionary tool, part of the Direct-to-Film (DTF) printing technique, empowers companies to maximize print efficiency while delivering unmatched quality in custom apparel. By utilizing the DTF Gangsheet Builder, businesses can create intricate designs on a single sheet, catering to the rising demand for personalized clothing options. Such flexibility not only enhances product offerings but also significantly reduces waste, ultimately lowering costs. As we explore the benefits and strategies surrounding this powerful printing technology, you’ll discover how the DTF Gangsheet Builder can take your printing ventures to new heights.

The concept of the DTF Gangsheet Builder is rooted in the advancement of Direct-to-Film technology, revolutionizing the way print shops approach custom garment creation. Often termed as a game-changer in printing techniques, this tool simplifies the process of aligning multiple designs on one film, ensuring efficient use of materials while producing high-quality transfers. As direct printing trends gain momentum, the importance of innovative solutions like the gangsheet builder becomes imperative for businesses looking to stay ahead in the competitive custom apparel market. With personalized products increasingly sought after, the versatility offered by this method provides a significant edge. Embracing such advancements not only enhances operational efficiency but also aligns perfectly with contemporary market demands.

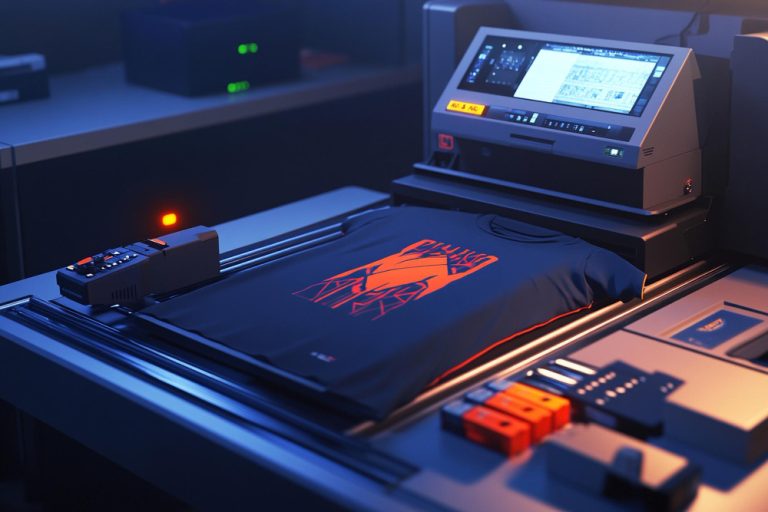

The Advantages of Direct-to-Film Printing for Custom Apparel

Direct-to-Film (DTF) printing has emerged as a game-changing solution for the custom apparel industry. This innovative technique allows businesses to produce vibrant, full-color designs that adhere seamlessly to various fabrics, making it highly versatile. Unlike traditional methods like screen printing, DTF printing eliminates many of the production limitations, enabling printers to create intricate designs without the need for expensive setup costs. As a result, the custom apparel market, fueled by consumer demand for personalized products, has seen a significant increase in companies adopting DTF technology to elevate their offerings.

Moreover, DTF printing offers a unique advantage by enabling low-volume orders without sacrificing quality. This flexibility is particularly beneficial for businesses that cater to niche markets or seasonal trends, as it allows them to respond quickly to changing customer preferences. Enhanced durability and washability of DTF prints are additional factors contributing to its growing popularity among apparel businesses, solidifying its position as a top choice for custom printing solutions.

Maximizing Efficiency with the DTF Gangsheet Builder

The DTF Gangsheet Builder is an innovative tool that enables printing businesses to optimize their production processes significantly. By creating a layout that combines multiple designs on a single film sheet, printers can maximize material use and minimize waste. This efficiency not only leads to cost savings but also reduces the time spent setting up individual prints. As a result, businesses can fulfill orders more quickly, enhancing customer satisfaction and enabling them to take on larger volumes of work without overwhelming their resources.

Incorporating the DTF Gangsheet Builder into your operations can also lead to more sustainable practices within the printing industry. With reduced waste and increased utilization of materials, businesses can position themselves as environmentally conscious, appealing to a growing base of eco-aware consumers. As companies strive to improve their operations, investing in tools like the DTF Gangsheet Builder can pave the way for innovation and success in the competitive landscape of custom apparel.

Key Tips for Optimizing Your DTF Printing Workflow

To fully harness the benefits of DTF printing and the DTF Gangsheet Builder, it’s essential to implement effective optimization strategies. One critical tip is to select high-quality inks and adhesives specifically designed for DTF technology. Quality products enhance print vibrancy while ensuring durability and long-term performance, which are vital for satisfying customer expectations in the fast-paced custom apparel market. In addition, researching and accumulating knowledge about these materials will enable printers to make informed decisions that benefit their output quality.

Furthermore, utilizing advanced software for layout design can dramatically streamline the printing process. Numerous programs are available that cater to DTF printing needs, offering features for gang sheet creation that can automate and simplify design arrangements. By embracing technology, printing businesses can reduce human error, decrease setup times, and increase productivity—a crucial step for businesses looking to thrive amid growing market competition.

Navigating Market Trends Influencing DTF Adoption

As the demand for personalized products surges, understanding market trends is key to successfully adopting DTF printing technology. The custom apparel market has seen sustained growth driven by a cultural shift towards self-expression and individuality, prompting consumers to seek out unique clothing items. Printing businesses that stay attuned to these evolving trends are better equipped to meet customer demands and seize opportunities within this burgeoning sector.

By integrating DTF printing into their offerings, businesses can tap into these trends while maintaining a competitive edge. Leveraging customer insights to adapt product designs and utilizing DTF technology to provide customization options not only fulfills current market demands but also positions companies favorably for future growth. This proactive approach ensures that businesses are not only keeping pace with market developments but are also setting themselves apart as leaders in the field of custom apparel printing.

Addressing Challenges in DTF Printing

While the advantages of DTF printing are clear, it is essential to recognize the challenges that businesses may face during the transition to this technology. Common issues include maintaining print consistency across batches and the initial costs associated with acquiring high-quality equipment. However, these challenges can be effectively managed through strategic planning and investment in training and development.

Investing in quality printers and materials, while initially costly, will ultimately improve output consistency and product quality. Furthermore, providing thorough training for staff on DTF printing techniques and equipment maintenance can drastically reduce errors and enhance overall production efficiency. By addressing these challenges head-on, printing businesses can establish a solid foundation for growth and customer satisfaction in the increasingly competitive custom printing landscape.

Conclusion: Embracing the Future with DTF Gangsheet Builder

The DTF Gangsheet Builder represents a pivotal tool for printing businesses aiming to enhance their operational efficiency while delivering exceptional quality in custom apparel. As the printing industry continues to evolve with advancements in technology, those who embrace these tools will find themselves well-positioned to thrive amid growing competition. This innovation not only streamlines production processes but also enables businesses to offer personalized products that meet the rising consumer demand for unique and meaningful items.

By staying informed of industry trends and continually optimizing their workflows, printing companies can leverage the benefits of DTF technology to boost productivity and profitability. As competition intensifies in the custom apparel market, businesses that adapt and innovate will not only survive but flourish. The DTF Gangsheet Builder is not just a tool; it’s a gateway to future success in the dynamic world of printing.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it benefit printing businesses?

The DTF Gangsheet Builder is a specialized tool used in Direct-to-Film (DTF) printing that allows businesses to arrange multiple designs on a single sheet. This method maximizes material use and minimizes waste, leading to greater efficiency and lower production costs for printing businesses. By utilizing the DTF Gangsheet Builder, companies can produce custom apparel more effectively and economically.

How does DTF technology enhance custom apparel production?

DTF technology enhances custom apparel production by enabling vibrant and durable prints to be transferred directly onto various fabric types. This flexibility allows printing businesses to cater to a wider range of customer preferences and tap into the growing market for personalized products. The DTF Gangsheet Builder complements this technology by allowing efficient arrangement of designs to reduce waste.

What are the best practices for using a DTF Gangsheet Builder?

To effectively use a DTF Gangsheet Builder, consider employing advanced software for layout automation, regularly maintaining your printing equipment, and investing in high-quality inks and adhesives. These best practices will enhance print quality, improve efficiency, and ensure that your printing business remains competitive in the custom apparel market.

What types of fabrics can be used with DTF printing?

DTF printing is compatible with a wide range of fabrics, including cotton, polyester, and fabric blends. This versatility makes it an excellent choice for custom apparel production, allowing businesses to offer a variety of products to meet diverse customer demands. The DTF Gangsheet Builder further optimizes usage across different fabric types.

Why is market knowledge important for DTF printing businesses?

Market knowledge is crucial for DTF printing businesses because it helps them stay ahead of trends in the custom apparel sector. By understanding consumer preferences, businesses can tailor their offerings to meet current demands and take full advantage of DTF technology’s capabilities for creating unique products.

How can DTF printing businesses overcome challenges related to production consistency?

To overcome challenges related to production consistency in DTF printing, businesses should invest in high-quality equipment and regularly train staff on DTF techniques. Consistent maintenance of printing machines and thorough employee training can significantly improve output quality, thereby enhancing customer satisfaction and trust.

| Key Point | Description |

|---|---|

| Understanding DTF Technology | DTF printing transfers vibrant designs onto fabrics using a special film, making it suitable for various materials. |

| What is a DTF Gangsheet Builder? | A tool that arranges multiple designs on a single sheet to maximize material usage and minimize waste. |

| Insider Tips | 1. Select quality adhesives and inks. 2. Utilize advanced design software. 3. Regularly maintain equipment. 4. Stay updated on market trends. 5. Invest in employee training. |

| Market Trends Influencing DTF Adoption | Growing demand for personalized products and custom clothing is driving DTF adoption in the printing industry. |

| Challenges and Solutions | Challenges include print consistency and equipment costs. Solutions involve investing in quality gear and staff training. |

Summary

DTF Gangsheet Builder is revolutionizing the printing business landscape by allowing companies to efficiently produce high-quality custom garments. By understanding the principles of DTF printing and utilizing productivity-enhancing tools such as the Gangsheet Builder, businesses can meet market demands while managing costs effectively. Embracing this innovative technology not only improves operational efficiency but also positions printing companies favorably in a rapidly evolving market. This is a crucial step for entrepreneurs looking to thrive in the competitive world of custom printing.