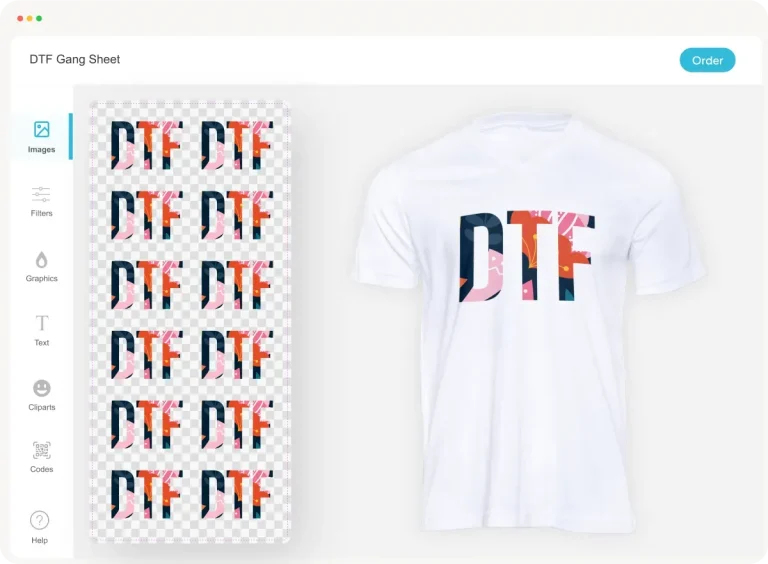

DTF gangsheet builder is redefining how small print shops manage multi-design runs, pairing intelligent layout with tangible production gains. In the fast-paced arena of DTF printing, this tool helps maximize output by packing multiple designs, sizes, and colors onto a single sheet. By automating placement and color alignment, it supports a smoother DTF production workflow and reduces setup time. The result is improved print shop efficiency, lower material waste, and more consistent results across orders. With compatibility to DTF printing software and proven gangsheet layout practices, it delivers faster turns and scalable capacity.

Viewed through an LSI lens, the concept becomes a batch packing tool that consolidates multiple designs onto a single transfer sheet. Designers and operators benefit from a layout optimizer that pre-plans color blocks, margins, and transfer zones, reducing manual adjustments. This approach aligns with the broader DTF printing software ecosystem and supports a streamlined production workflow. Alternative terminology might call it a multi-design sheet planner or a print job consolidation utility that maintains color fidelity and saves substrate. In practice, teams see faster setup, fewer errors, and a smoother path from concept to customer delivery.

DTF gangsheet builder: Boosting Print Shop Efficiency and Throughput

Using a DTF gangsheet builder allows a small print shop to maximize each print run by arranging multiple designs on a single sheet. This strategic gangsheet layout reduces substrate waste, speeds up setup, and increases transfers per batch, directly boosting print shop efficiency. The approach aligns with DTF printing best practices and integrates smoothly with DTF printing software to maintain color fidelity across designs.

Order mixes with diverse artwork benefit from templates and automated placement: predefined safe print areas, transfer zones, and margins are populated by the builder, which instantly optimizes positioning and color blocks. Staff spend less time on manual realignments and retools, enabling a more scalable DTF production workflow and more consistent results across runs.

Optimizing DTF Production Workflow with Smart Gangsheet Layout and Software

When the gangsheet layout is designed to work with your DTF printing software, the production workflow becomes a coherent sequence: design, preflight, layout, print, transfer, and finish. This orchestration reduces downtime between jobs and improves throughput without sacrificing print quality or color accuracy, aligning with the needs of busy apparel and merchandise printers. The integrated system supports DTF printing software to ensure tight color matching and reliable transfers.

Best practices include building templates for common garment types, locking in color profiles, and running small tests to validate placements before full runs. Over time, this approach reduces reprints, minimizes waste, and makes the DTF production workflow more predictable and scalable, helping small shops meet growing demand while safeguarding margins.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it boost print shop efficiency in the DTF production workflow?

A DTF gangsheet builder is a workflow tool that arranges multiple designs on a single gangsheet before printing. By pre-planning layout, standardizing color management, and automating placement, it increases print shop efficiency within the DTF production workflow. Benefits include more transfers per sheet, shorter setup times, reduced substrate waste, and faster turnarounds when used with reliable DTF printing software.

How does intelligent gangsheet layout in a DTF gangsheet builder, together with DTF printing software, maximize transfers per sheet while maintaining color accuracy?

Intelligent gangsheet layout uses templates, color profiles, and batch processing to pack designs efficiently on each sheet, minimizing waste and misalignment. When paired with DTF printing software, it ensures consistent color output and predictable throughput, reducing reprints and aligning with the overall production workflow for small shops.

| Key Point | Description | Benefits |

|---|---|---|

| What is a DTF gangsheet builder? | Specialized software/workflow tool that arranges multiple designs on a single print sheet (gangsheet) to optimize space and reduce waste. | More shirts per run; less setup; better consistency across orders. |

| Why it matters for small shops | Addresses tight deadlines, varying order sizes, and the drive to minimize waste while maximizing output. | Faster turnarounds; reduced ink/substrate costs; scalable production. |

| How it optimizes production | Automates placement, aligns color palettes, and optimizes margins and heat-transfer zones. | Higher item counts; less manual intervention; fewer errors. |

| Core features | Intelligent layout; color management; batch processing; preview/validation; export-ready outputs. | Efficient, repeatable layouts; accurate color reproduction; streamlined file outputs. |

| Ecosystem alignment | Operates within the broader DTF workflow with printers, heat presses, and ink systems; translates designs into optimized gang sheets. | Reduces downtime; maintains steady production cadence. |

| Implementation steps | 1) Gather standard artwork; 2) Define templates; 3) Build the gangsheet; 4) Validate/test; 5) Print/finish. | Clear, repeatable setup process; faster onboarding; fewer misalignments. |

| Economic/efficiency benefits | Throughput gains, material savings, consistency, and faster onboarding/scalability. | Better margins and ability to handle higher demand. |

| Best practices & pitfalls | Templates, color accuracy, plan for color counts, proactive testing, and layout review; avoid over-reliance on automation and account for substrate variability. | Improved reliability; fewer reprints; adaptable to different fabrics. |

Summary

DTF gangsheet builder is essential for small print shops aiming to scale without sacrificing quality or profitability. It streamlines how multiple designs are packed onto each sheet, reduces setup time, and standardizes color handling to deliver faster, more consistent runs. By integrating with DTF printers, heat presses, and ink systems, the right gangsheet tool turns busy days into predictable production, boosts output, and improves margins on every order.