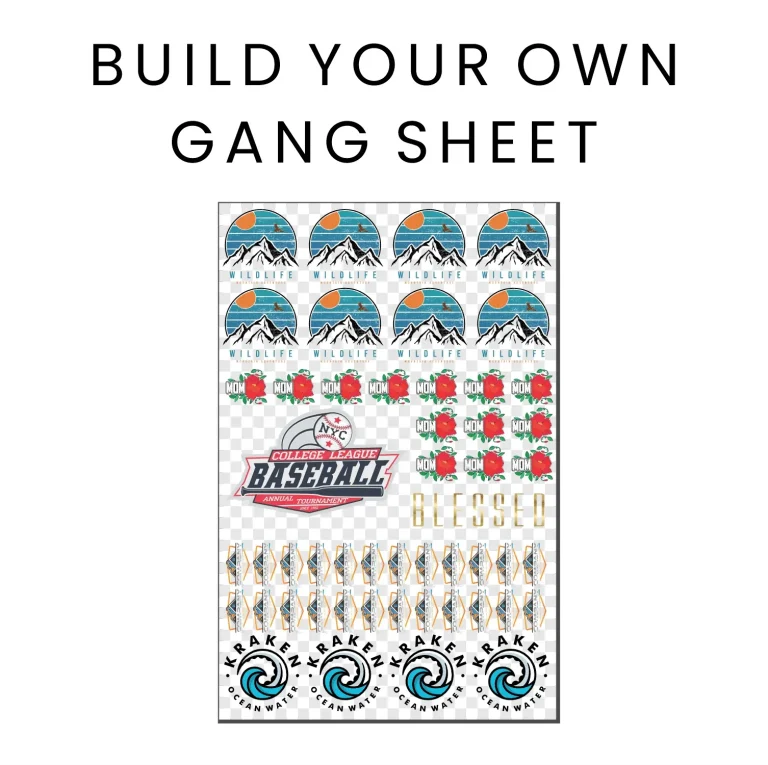

DTF gangsheet builder is transforming how small shops approach garment transfers, offering a single, purpose-built tool to organize multiple designs and sizes on one film sheet, reduce handling, and accelerate turnarounds while preserving print quality and color fidelity across diverse product lines, from tees to bags. From planning to production, this tool supports the entire DTF printing workflow by consolidating design placement, color management, and printer profiles into a cohesive, repeatable process that minimizes waste and speeds setup, so teams can move from concept to customer-ready transfers faster. A well-implemented gangsheet setup reduces scrap, speeds production, and elevates the small print shop workflow while boosting DTF production efficiency for ranges from T-shirts to tote bags, enabling more predictable scheduling and better capacity planning. By integrating templates, pre-approved proofs, clear cut lines, and margins, teams can apply heat transfer best practices consistently and deliver durable transfers with color accuracy and reliable adhesion across fabrics. In practice, this approach yields clearer job costing, shorter lead times, improved client satisfaction, and scalable capacity as demand grows, turning a lean shop into a more competitive, repeatable operation.

In plain terms, imagine a sheet-layout tool for DTF that bundles several designs into one production run, acting as a planner for multi-design projects and a bridge from artwork to finished transfers. Alternatively, you might call it a layout optimizer, a gangsheet designer, or a batch-pack processor, all grounded in latent semantic connections to terms like multi-design packing, print-ready sheets, and color-managed outputs that help search engines and readers alike understand the topic. Using these descriptive labels, small shops can streamline workflows, reduce waste, and deliver consistent results more reliably, reinforcing the core ideas described in this guide while keeping the language approachable.

DTF Gangsheet Builder for Small Shops: Boost DTF Production Efficiency and Streamlined Gangsheet Setup

In the context of the DTF printing workflow, a gangsheet builder lets you pack multiple designs and sizes on one film sheet, maximizing sheet utilization and reducing the number of print runs per order. For small print shop workflows, this gangsheet setup translates into higher uptime, predictable production schedules, and less handling between steps, which directly boosts DTF production efficiency.

To implement effectively, choose a tool with intuitive drag-and-drop layout, printer profile compatibility, and a robust template library for gangsheet setup. Build reusable templates for common product lines, ensure color management aligns with your RIP software and ICC profiles, and keep assets organized with clear naming. With these steps, your small print shop workflow becomes more efficient and scalable, delivering faster turnarounds with consistent quality. Pair this with templates-driven layouts and robust preflight checks to minimize misprints.

Heat Transfer Best Practices in the DTF Printing Workflow and Layout

To uphold heat transfer best practices, start with solid pre-press settings: confirm platen temperature, pressure, and time for each fabric type, and use test swatches to validate adhesion before a full run. This aligns with the DTF printing workflow by preventing misprints and ensuring consistent color and transfer performance across garments. Emphasize a clean, repeatable small print shop workflow that reduces variability between batches.

During printing and post-press, maintain layer separation, verify ink compatibility with powders and films, and condition transfers after pressing to improve durability and peel results. For a small shop, careful post-heat conditioning and garment prep guidelines, plus simple documentation of results, help sustain DTF production efficiency and ensure consistent results across product lines.

Frequently Asked Questions

What is a DTF gangsheet builder and how can it improve DTF printing workflow and small print shop workflow?

A DTF gangsheet builder is software or a defined workflow that arranges multiple designs on a single film sheet before printing. It improves the DTF printing workflow by maximizing sheet utilization, speeding up gangsheet setup, and reducing waste, which enhances the small print shop workflow. With standardized templates and solid color management, you’ll achieve higher DTF production efficiency and more consistent heat transfer results.

What should a small print shop consider when selecting a DTF gangsheet builder to optimize gangsheet setup and DTF production efficiency?

Look for ease of use (drag-and-drop layouts and automatic packing), strong software compatibility with your design tools and printer RIP, a library of templates, robust color management, and scalable pricing. Ensure it fits your small print shop workflow and aligns with heat transfer best practices to maximize DTF production efficiency and minimize waste.

| Aspect | Key Points |

|---|---|

| What it is | A tool (software or hardware-enabled workflow) that arranges multiple designs, sizes, or colorways on a single sheet to minimize material use, speed production, and simplify the post-press process. |

| Core benefits | Increases production efficiency; improves consistency and quality control; reduces waste; speeds up setup times. |

| Choosing the right tool | Focus on ease of use, software compatibility, template library, color management and RIP integration, scalability/pricing, and available support/community. |

| Best practices (implementation) | Standardize file naming; build templates/presets; align color management; organize artwork and margins; define print order and batching; automate where possible; implement quality checks at every stage. |

| Design & layout | Maximize sheet utilization; balance color areas; consider substrate differences; include clear cut lines and margins; test layouts to verify color reproduction and alignment. |

| Production workflow | Pre-press planning; aligned print and cure sequence; post-press handling; inventory integration; documentation and traceability for future orders. |

| Quality control & heat transfer | Pre-press settings, ink/film compatibility, layered separation, post-heat conditioning, and garment preparation guidance to preserve transfer longevity. |

| Common pitfalls | Overcrowded sheets; color misalignment; inconsistent garment behavior; poor file quality. Use preflight checks and robust templates to mitigate. |

| SOPs & training | File intake and preflight, gangsheet layout steps, print and post-press settings by material, quality checkpoints, inventory/waste tracking, and escalation handling. |

| ROI & quick-start | Lower per-unit waste, faster throughput, better consistency, and efficient use of equipment; start with a 30-day plan: define lines, create templates, run pilots, refine layouts, and scale gradually. |

Summary

Conclusion: A DTF gangsheet builder is a strategic tool that unlocks the potential of a small print shop by organizing multiple designs and sizes on a single sheet to maximize throughput and minimize waste. Paired with a solid DTF printing workflow, thoughtful gangsheet setup, and disciplined production efficiency practices, it helps deliver high-quality transfers faster with less waste and greater predictability. By investing in templates, template-driven layouts, and robust quality controls, a small shop can scale to meet growing demand while maintaining the attention to detail customers expect from a trusted local provider.