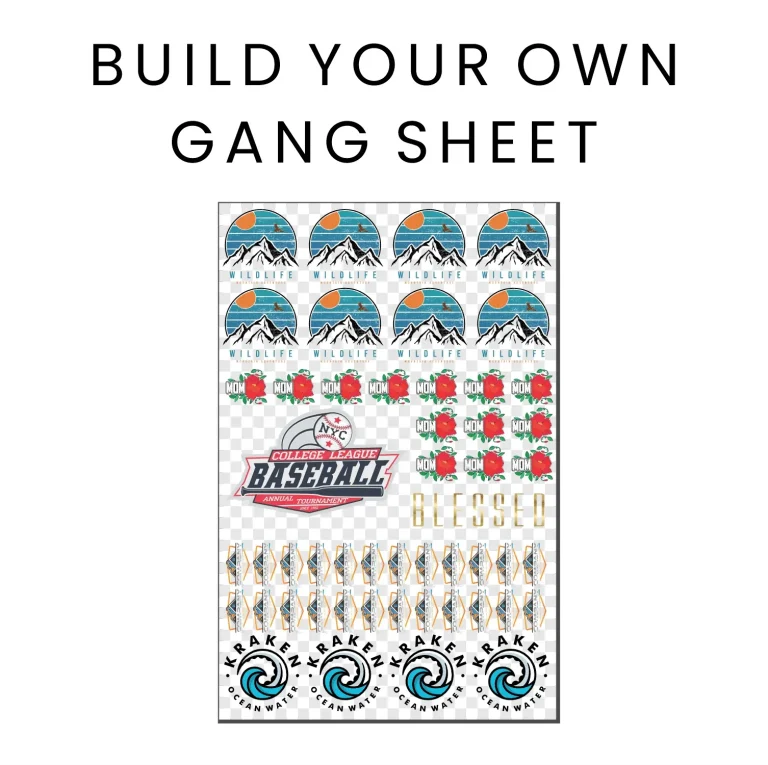

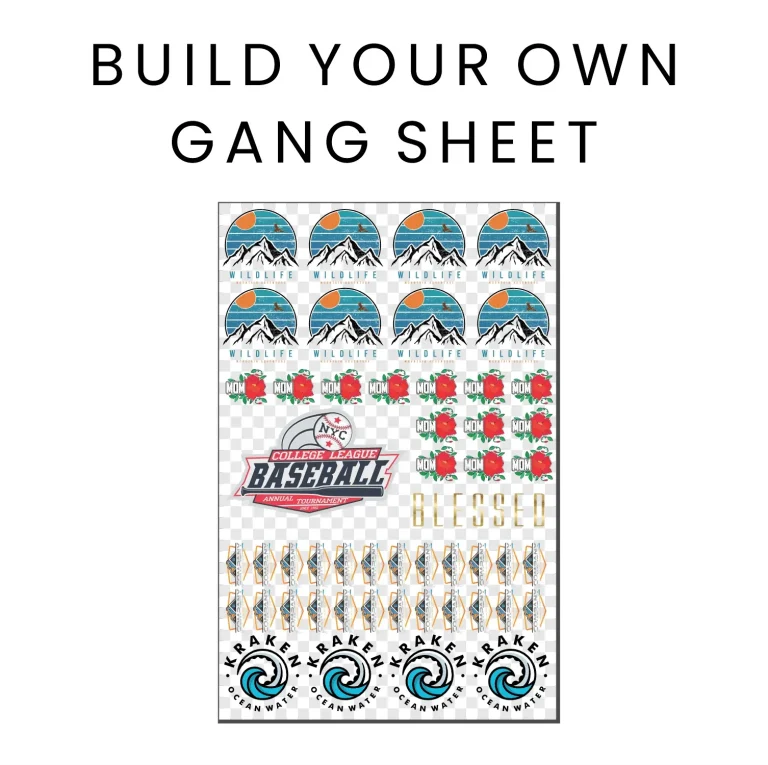

DTF Gangsheet Builder is your gateway to streamlined, production-ready gang sheets for Direct-to-Film printing. In this guide, you’ll learn how to organize multiple designs on a single sheet, with DTF gangsheet builder tips to reduce setup time and material waste. The tool integrates color management, template workflows, and batch processing to improve DTF printing workflow optimization. By applying tips on layout, margins, and safe zones, in line with DTF gang sheet layout best practices, you’ll hit color targets more consistently. Whether you’re solo or in a studio, these techniques translate into faster runs, less rework, and better overall quality, and they show how to create a DTF gang sheet efficiently.

Viewed through a broader lens, this concept becomes a dedicated sheet-composition system for heat-transfer printing, where multiple designs are mapped onto one substrate. Using Latent Semantic Indexing principles, we refer to the same idea as batch layout optimization, multi-design sheet planning, or a print-prep toolkit that speeds setup and maintains accuracy. Key ideas include grid-based placement, consistent margins, color-channel management, and reusable templates—terms that reinforce the same goal of efficient production. As you explore this topic, you’ll encounter references to related concepts such as DTF design optimization for gang sheets and practical guidance on achieving consistent color and placement. Ultimately, the focus remains on reliable, scalable results that reduce waste and cut downtime across runs.

DTF Gangsheet Builder: Advanced Techniques for Efficient Gang Sheets

Mastering the DTF Gangsheet Builder starts with thoughtful planning and a strong foundation in layout fundamentals. This is where you’ll encounter essential DTF gangsheet builder tips that help you maximize sheet usage, minimize waste, and streamline the design-to-print workflow. Learn how to create a DTF gang sheet with a clear plan: gather all artwork, define colorways and white underbase needs, and build a reusable template that enforces grids, safe zones, and consistent margins. By aligning these steps with DTF printing workflow optimization, you’ll reduce rework and achieve repeatable results across batches.

A core part of how to create a DTF gang sheet efficiently is establishing a stable grid, margins, and alignment. The DTF gang sheet layout best practices emphasize predictable placement, safe zones, and uniform spacing so color separations stay intact and prints remain legible. Rotate and group designs to maximize sheet utilization while preserving readability and garment placement, and design a test-print strategy to verify scale before committing to a full run. This approach ties directly into DTF design optimization for gang sheets and helps ensure consistency across production cycles.

Beyond planning and basic layout, automation and templates play a pivotal role in DTF printing workflow optimization. Create master templates, leverage batch processing to reduce tool changes, and implement quick preflight checks to catch misalignments or clipping before printing. These practical steps—tied to DTF gangsheet builder tips like templating, naming conventions, and automated spacing—drive faster turnaround times and more reliable color outcomes, reinforcing the broader goal of efficient, high-quality gang-sheet production.

DTF gang sheet layout best practices for high-efficiency production

Effective gang sheet design hinges on rigorous layout discipline. Start with a consistent grid (e.g., 3×5 or 4×6) and precise margins to ensure predictable placement across multiple designs. Use safe zones within each design to prevent edge clipping, and align all elements to a common origin so spacing remains uniform from sheet to sheet. This mirrors the core ideas of DTF gang sheet layout best practices and supports seamless color separation and print accuracy on every run.

Color management and artwork quality are central to professional results. Maintain standard color profiles (like sRGB for design work) and map color layers to the printer’s channels, including dedicated white underbase layers where needed. A balanced mix of vector and high-resolution raster art keeps edges crisp while staying friendly to the sheet’s limits. Pair these practices with a robust proofing workflow to verify color relationships before printing, aligning with DTF design optimization for gang sheets and reinforcing DTF printing workflow optimization.

To push efficiency further, prioritize automation, preflight checks, and batch processing. Use templates for repeat projects, batch similar tasks, and embed metadata in design names for easy tracking. A disciplined approach to naming, versioning, and preflight helps catch issues early and reduces waste, embodying the spirit of continuous improvement in DTF printing workflow optimization and the practical application of DTF gang sheet layout best practices.

Frequently Asked Questions

DTF gang sheet layout best practices: How can I use the DTF Gangsheet Builder to maximize sheet space while preserving color accuracy and consistency across designs?

Key guidelines for using the DTF Gangsheet Builder: – Plan first and use a reusable template. – Use a consistent grid with defined margins and safe zones to prevent edge clipping. – Align designs to the grid origin and group by color steps to minimize ink changes. – Separate white underbase from color layers and maintain standard color profiles (e.g., sRGB). – Run a small test print and perform a quick preflight before exporting. Following these tips supports DTF design optimization for gang sheets and overall layout best practices while keeping production efficient.

How to create a DTF gang sheet with the DTF Gangsheet Builder: what steps align with efficient DTF printing workflow optimization and DTF design optimization for gang sheets?

Practical steps: – Gather all artwork and confirm final sizes; decide which designs need white underbase. – Create a master template with a grid and safe zones. – Place designs on the grid, grouping items by color steps, and assign white underbase where needed. – Keep color layers separate for easy adjustments and verify spacing with a test print. – Preflight, export, and run a small proof before the full batch to maximize production efficiency and consistency, aligning with DTF printing workflow optimization and DTF design optimization for gang sheets.

| Aspect | Key Points |

|---|---|

| What is the DTF Gangsheet Builder? | Tool to arrange multiple designs on a single sheet to reduce setup time and waste; enables color management and batch printing. |

| Core goal | Optimize space while preserving print quality and color accuracy; intelligent layout, margins, and color management. |

| Planning foundation | Gather artwork and confirm sizes, define colorways/white underbase needs, create naming conventions, choose sheet size and margins, build a reusable template. |

| Layout fundamentals | Use a consistent grid; designate safe zones and margins; manage orientation/rotation; group similar designs; perform test prints. |

| Color management | Use standard color profiles, separate and layer wisely for white underbase, balance vector/raster, avoid over-inking, use soft proofs. |

| Workflow optimization | Templates, batch processing, metadata, automation, preflight checks. |

| Pitfalls/practical tips | Misregistration, inconsistent color, bleed/edge clipping, large file sizes, naming mismatches; address with calibration, color workflow, and naming discipline. |

| Real-world example | Walkthrough: place 15 designs on 12×18 using a 3×5 grid, template, layers, preflight, export/print. |

| Outcome | Improved speed, consistency, reduced waste, and higher profitability through planning and automation. |

Summary

DTF Gangsheet Builder is a versatile framework for organizing multiple designs on a single print sheet, designed to reduce setup time, minimize waste, and maintain color fidelity. By planning ahead, using a consistent grid, careful margins, and robust color management, shops can achieve predictable results across batches while simplifying color separations and underbase handling. The approach emphasizes templates, batch processing, metadata, and preflight checks to streamline production and improve profitability. Real-world workflows show how a 12×18 sheet can accommodate many designs with a 3×5 grid using reusable templates and clear naming conventions. Overall, adopting the DTF Gangsheet Builder leads to faster turnarounds, fewer reworks, and higher-quality outputs, making it an essential practice for serious DTF operations.