DTF gangsheet builder unlocks new levels of efficiency for apparel printers, enabling teams to maximize material usage and reduce downtime by transforming how designs are grouped and transferred. By aligning the DTF printing workflow with a smart gang sheet design for DTF, shops can streamline initialization, minimize ink changes, and achieve more consistent results across batches. When you scale print runs, this approach boosts bulk DTF printing efficiency, simplifies file preparation, and helps you predict capacity, making it easier to meet rising demand without sacrificing quality. A well-tuned system also supports DTF production optimization by standardizing color management, bleed control, and layout rules so that every sheet comes with fewer surprises in production. With clear workflows, reusable templates, and practical QA checks, the DTF gangsheet builder becomes a repeatable driver of throughput, cost savings, and reliable color fidelity in high-volume environments.

An alternative way to describe this capability is as a gang sheet design optimizer for DTF, a batch layout engine that packs multiple designs onto a single media sheet for efficient transfer. Other terms you may encounter include a multi-design tiling tool, a sheet packing optimizer, or a batch-transfer workflow that smooths the end-to-end DTF process. Viewed through an SEO lens, these concepts connect to the broader goal of improving the DTF production pipeline and the DTF printing workflow, aligning artwork, color, and substrate handling to reduce waste and downtime. For teams, adopting these terms helps clarify responsibilities across design, prepress, and production while staying aligned with modern scalability objectives.

DTF gangsheet builder: accelerate scaling print runs and optimize DTF production

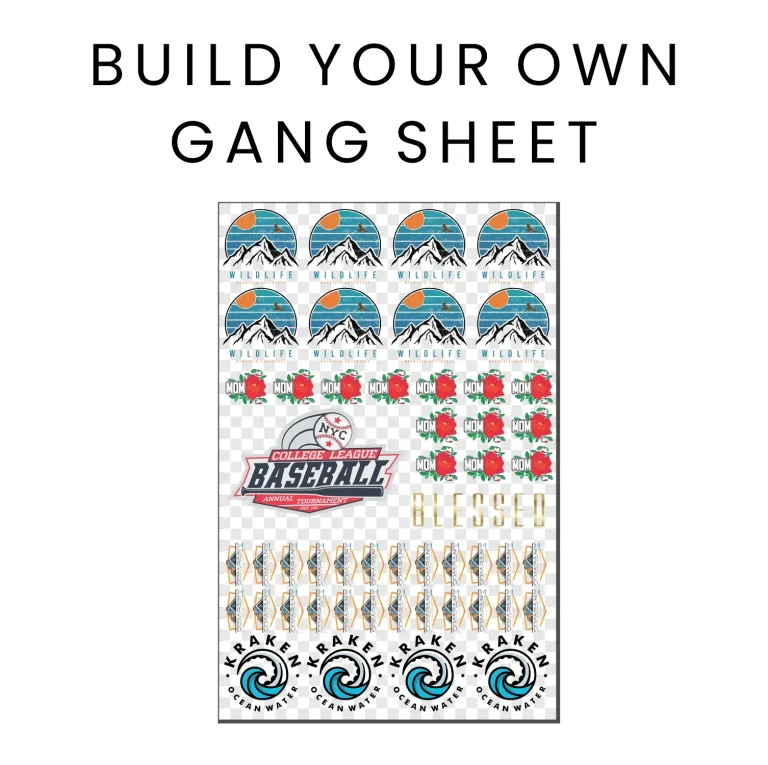

A DTF gangsheet builder slots into the DTF printing workflow, enabling multi-design tiling on a single gang sheet while respecting bleed, margins, and substrate constraints. By automating placement and color-aware packing, it minimizes color changes and ink movements, translating into higher bulk DTF printing efficiency and a smoother path to scale print runs. This tool also supports export-ready files aligned with RIP software, helping maintain DTF production optimization from prepress through to transfer.

Beyond the technical fit, the DTF gangsheet builder supports a repeatable, data-driven process that reduces waste and accelerates throughput. Designers and prepress operators can collaborate on standardized gang sheet templates, improving color management discipline and predictability across large orders. As a result, brands can scale print runs without sacrificing accuracy, delivering consistent results at higher volumes while keeping production costs in check.

Gang sheet design for DTF: best practices to maximize efficiency in bulk production

Effective gang sheet design for DTF begins with planning layouts that respect garment sizes, transfer areas, and substrate variability. Establish consistent margins and bleed to prevent unintended white edges, and apply color management discipline across all designs on a sheet to minimize color shifts when packed together. Automating placement where possible reduces manual effort and speeds up the prepress phase, making it easier to scale print runs with confidence.

In practice, focus on a repeatable workflow: validate files for tiling, test a subset of layouts, and maintain centralized templates for easy reuse. Coordinate with RIP settings and printer profiles to ensure color proofs transfer accurately to production, while tracking yields, waste, and time per sheet to drive continuous DTF production optimization. By documenting each gang sheet configuration and version, teams can reproduce successful layouts at scale and reliably meet bulk production targets.

Frequently Asked Questions

How can a DTF gangsheet builder improve bulk DTF printing efficiency and scale print runs?

A DTF gangsheet builder enables multi-design tiling on a single sheet, reducing setup time between designs and increasing throughput for bulk DTF printing efficiency. Features like color-aware packing, margin and bleed control, and sparse versus dense packing help maximize substrate use while preserving color accuracy across designs. Real-time preview and simulation catch layout issues before production, while export-ready files ensure seamless integration with RIP software and your DTF printing workflow. Together, these capabilities support scalable production, lower waste, and more predictable turnaround across larger print runs.

What features should I prioritize in a DTF gangsheet builder to optimize gang sheet design for DTF and production optimization?

To optimize gang sheet design for DTF and production optimization, prioritize features such as multi-design tiling, color-aware packing, precise margin and bleed control, and flexible packing modes (sparse or dense). Look for real-time preview, export formats compatible with your RIP, automated layout placement, and robust color management (ICC profiles and ink limits). Also evaluate integration with order management, templates for repeat jobs, and built-in QA workflows to sustain scaling print runs and improve overall production efficiency.

| Aspect | Key Points |

|---|---|

| What is a gangsheet? |

|

| Why it matters for DTF printing |

|

| Key features of a DTF gangsheet builder |

|

| From planning to production: a practical workflow |

|

| Why the DTF printing workflow benefits from gang sheets when scaling |

|

| Best practices for designing gang sheets that scale |

|

| Real-world example: scaling a 500-unit run with a single gang sheet strategy |

|

| Common challenges and how to overcome them |

|

| Integrating a DTF gangsheet builder into your broader production ecosystem |

|

| The future of scalable DTF production with gang sheets |

|

Summary

DTF gangsheet builder is a strategic tool for scaling production in the apparel industry. It combines multi-design tiling, color-aware packing, and precise margins to optimize a DTF printing workflow and gang sheet design for DTF, delivering bulk DTF printing efficiency and predictable timelines as you scale print runs. By adopting best practices, integrating with your production ecosystem, and continually refining layouts through data, you can achieve faster turnarounds, consistent color fidelity, and a scalable process that grows with demand.