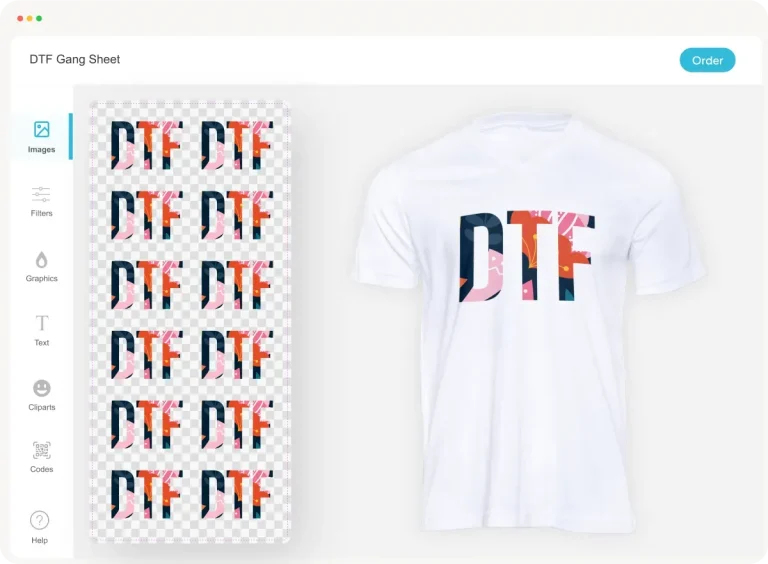

DTF Gangsheet Builder revolutionizes how shops approach layout planning by turning multiple designs into a single, efficient workflow, supporting multi-design layouts. This robust tool supports DTF gangsheet layouts, allowing you to arrange designs with precision and minimize substrate waste. Within the DTF printing workflow, it helps manage color, margins, and bleed across a batch while maintaining consistency. Garment printing templates let you preview outcomes on different products and guide decisions, contributing to effective gangsheet optimization. Overall, adopting this builder boosts efficiency, reduces setup time, and scales production with clear, describable layouts you can rely on.

DTF Gangsheet Builder: Mastering Multi-Design Layouts for Efficient Production

The DTF Gangsheet Builder centralizes design management to unlock true efficiency through multi-design layouts. By assembling several designs onto a single gangsheet, shops can maximize surface area, minimize substrate changes, and dramatically cut setup time. This approach not only reduces material waste but also accelerates the production cycle, making it easier to scale operations without sacrificing print quality. In practice, embracing DTF gangsheet layouts means you can plan larger batches with confidence, knowing that every sheet is optimized for your garment printing workflow.

With the DTF Gangsheet Builder, you gain access to layout templates, alignment tools, and intuitive drag-and-drop capabilities that ensure precise margins and clear separations. The system supports color mapping and separation rules so that designs translate consistently across substrates. By leveraging garment printing templates within multi-design layouts, you can preview how each design will look on different products, preventing misalignment and ensuring a professional finish before production begins.

Optimizing the DTF Printing Workflow with Strategic Layouts and Templates

A well-executed gangsheet strategy accelerates the overall DTF printing workflow by reducing the number of print cycles and streamlining file preparation. By combining related designs into cohesive layouts, you improve batch consistency and simplify color management across orders. The emphasis on DTF gangsheet layouts and multi-design layouts supports faster turnovers and more predictable outputs, which is especially valuable for campaigns or seasonal releases.

Garment printing templates and careful gangsheet optimization play pivotal roles in quality control. Using templates helps verify how each design will align on actual garments, while consistent margins and standardized export settings safeguard print fidelity. This descriptive approach to layout planning—paired with color checks and proofs—minimizes reprints and keeps production smooth from design submission through final transfer.

Frequently Asked Questions

How does the DTF Gangsheet Builder streamline multi-design layouts and the DTF printing workflow?

The DTF Gangsheet Builder centralizes all designs, enabling efficient DTF gangsheet layouts and multi-design layouts on a single transfer sheet. It offers layout templates, precision alignment, color mapping, and export options to speed up the DTF printing workflow. By optimizing placement and margins, it reduces setup time, material waste, and color errors, improving throughput and consistency across batches.

How do garment printing templates and gangsheet optimization enhance performance in the DTF Gangsheet Builder?

Garment printing templates provide a live preview of how designs will render on real products, ensuring correct placement and scale. Combined with gangsheet optimization, they maximize sheet usage, minimize waste, and stabilize colors across runs. This leads to faster production, fewer reprints, and more consistent results within your DTF printing workflow.

| Key Point | Description |

|---|---|

| Definition of gangsheet and multi-design layouts | A gangsheet is a single sheet containing multiple designs arranged for printing. Multi-design layouts place several designs on one sheet to maximize surface usage, reduce waste, and improve batch consistency. |

| DTF Gangsheet Builder role | The DTF Gangsheet Builder provides layout templates, alignment tools, and export options to manage complex multi-design arrangements aligned with production needs. |

| Import and organize designs | Centralizes designs, tags by color, size, or product, and pulls them into a layout quickly. |

| Choose a layout strategy | Offers templates for garment sizes and printing requirements; start with a proven pattern and adjust as needed. |

| Arrange with precision | Drag-and-drop and alignment features help position each design with exact margins and bleed for clean separations. |

| Define color and separation rules | Color management tools map colors, define ink limits, and preview how colors translate on different substrates. |

| Preview, adjust, and export | Live preview of the gangsheet; tweak spacing rotation or placement, then export files in printer and RIP friendly formats. |

| Best Practices for Efficient Multi-Design Layouts | Plan with a production mindset; review total items garment sizes and required color separations to save adjustments later. |

| Maintain consistent margins and bleed | Uniform margins prevent edge clipping and ensure clean image borders across all designs on a sheet. |

| Group by color families | Organize designs with similar hues together to optimize ink usage and color matching. |

| Use garment printing templates | Templates help preview how each design will look on actual products, reducing misalignment and improving production accuracy. |

| Validate export settings | Ensure the final files reflect the correct resolution color space and file type required by your printer and RIP. |

| Run proofs and color checks | A quick proof print on a test sheet can catch color shifts or scaling issues before committing to a full batch. |

| Color Management and Quality Control | Color profiles simulate ink usage verify separations on the gangsheet layout for predictable results across batches. |

| A Practical Example | Imagine 12 new designs printed as two or three gang sheets by grouping similar palettes for faster production. |

| Advanced Tips for Gangsheet Optimization | Layer logically if supported by your printer; optimize for substrate variety; maintain a library of reusable templates; monitor edge cases; document the process. |

| Case Study: Scaling Up with a Gangsheet Strategy | A mid sized print shop shifted from one design per sheet to gangsheet driven production; mapping 24 designs into two gang sheets reduced waste by 18% and cut setup time by about 35% after standardizing color plans. |

Summary

DTF Gangsheet Builder unlocks faster production and consistent results at scale. By enabling DTF gangsheet layouts and multi-design layouts, it streamlines the DTF printing workflow and makes garment printing templates central to your process. This approach improves gangsheet optimization and reduces waste and setup time across batches. Building a library of layouts and iterating on your workflow lets teams scale while preserving quality. If you want to see a live demonstration or how the DTF Gangsheet Builder fits into your current operations, request a personalized walkthrough and start optimizing your designs today.