The DTF gangsheet builder is changing how shops plan every transfer, turning scattered designs into a cohesive production plan. By consolidating assets and color management, it supports a smoother DTF printing workflow and helps maintain heat transfer sheet alignment. With gangsheet automation and DTF gangsheet design, teams achieve higher efficiency and reduce waste across runs. This leads to improved consistency in garment printing, tight color control, and reliable results from the first print to the last. If your shop is scaling up, adopting a DTF gangsheet builder can deliver predictable throughput while preserving artwork integrity.

Viewed through an alternative lens, this tool functions as a DTF sheet planner that coordinates several designs into a single, print-ready run. As a layout engine, it respects margins, bleed, color fidelity, and sheet alignment across garments, delivering a repeatable production pipeline. Think of it as a design-to-sheet system that uses template-based workflows, centralized color management, and automated preflight checks to minimize misprints. In practical terms, adopting this approach supports consistent output, faster turnarounds, and smoother collaboration across teams handling multiple client orders.

DTF Gangsheet Builder: From Design to Sheet for Consistent Garment Printing

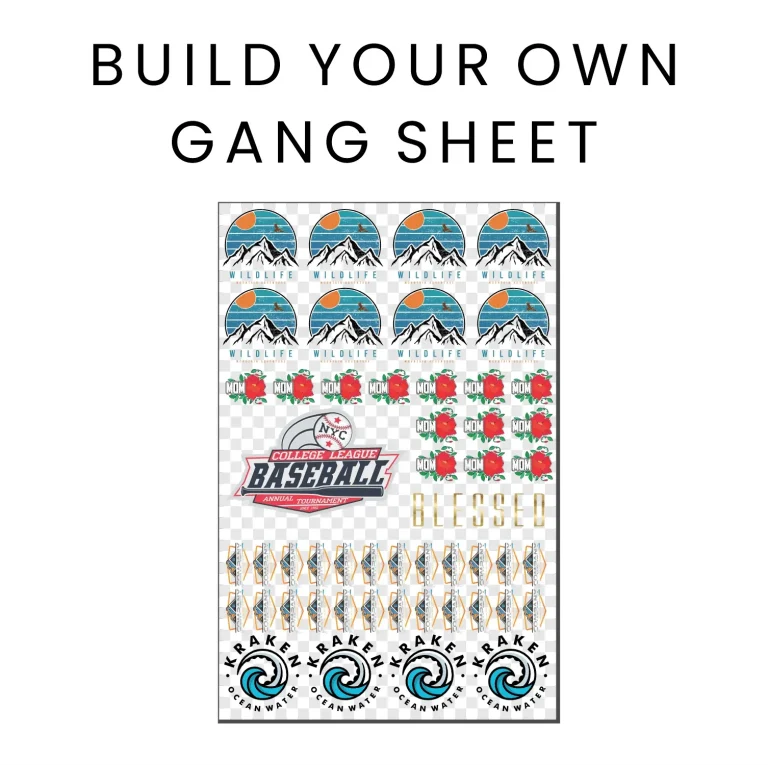

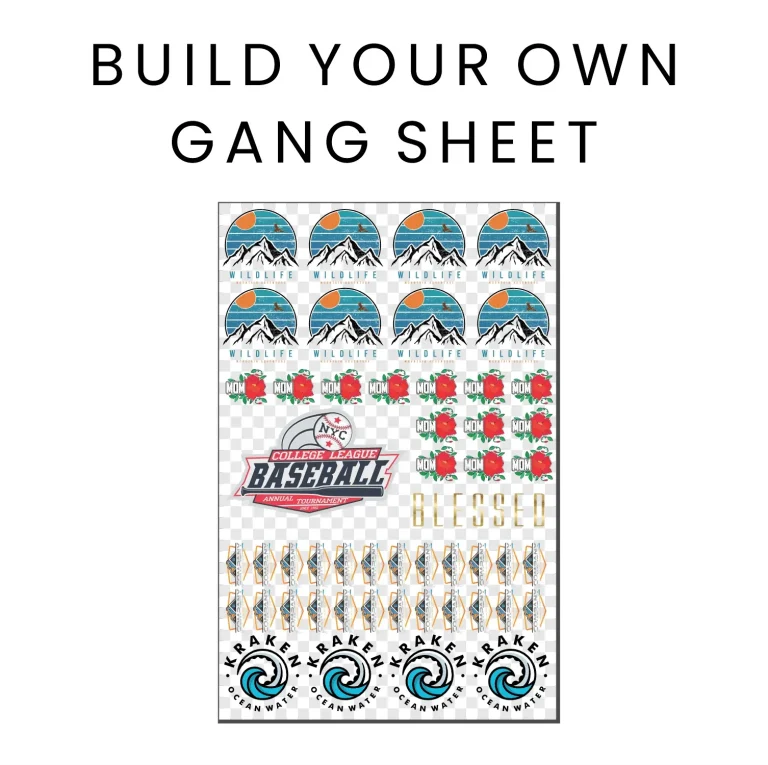

A DTF gangsheet builder unites design assets, color management, and layout logic into a single workflow that creates gang sheets. By consolidating art, palettes, and placement rules, this tool transforms disparate designs into a cohesive sheet that accommodates multiple garments and colorways with precision.

In practice, gang sheets are printed on a single sheet with a structured grid, fixed margins, bleed, and alignment marks. This enables a streamlined design-to-sheet workflow, where each artwork—regardless of size or colorway—inherits a single source of truth for color profiles and positioning. The result is improved DTF gangsheet design, more predictable color accuracy, and reliable registration across runs, which directly supports consistency in garment printing.

Enhancing Consistency and Efficiency with DTF Printing Workflow, Gangsheet Automation, and Heat Transfer Sheet Alignment

Gangsheet automation takes the guesswork out of layout, reducing manual placement and potential human error. By automatically optimizing how designs fit on the sheet, setting margins, and applying color profiles, factories can maintain a steady DTF printing workflow from design prep through to output. Automated checks and preflight routines further safeguard against misregistration, ensuring heat transfer sheet alignment remains precise across batches.

Adopting standardized color pipelines and mindful planning for size and garment diversity helps maintain consistency in garment printing even as orders scale. With centralized color management, predefined layouts, and test prints to validate alignment marks, teams can shorten lead times while preserving design integrity. This approach mirrors best practices for achieving reliable results and demonstrates how gangsheet automation and disciplined workflow management translate into tangible benefits like fewer reprints, reduced waste, and happier clients.

Frequently Asked Questions

How can a DTF gangsheet builder improve consistency in garment printing across multiple runs?

Using a DTF gangsheet builder, you centralize assets and enforce a unified color pipeline, which minimizes color drift and misregistration across runs. It streamlines the DTF printing workflow by automatically positioning designs with fixed margins, bleed, and alignment marks, and performing preflight checks to catch issues before printing. With version control for gangsheet templates and repeatable layouts, teams achieve repeatable results, reduce waste, and shorten lead times while maintaining consistency in garment printing from first to last piece.

Which features of a DTF gangsheet builder optimize heat transfer sheet alignment and streamline the DTF printing workflow?

Key features of a DTF gangsheet builder that improve heat transfer sheet alignment and efficiency include automated gangsheet design and layout optimization, centralized color management, and alignment marks that ensure precise registration. The tool supports multiple colorways and sizes while preserving a single source of truth, exports in printer-ready formats, and runs preflight checks to prevent misprints. This reduces waste, speeds throughput, and enhances the overall DTF printing workflow by delivering consistent, well-aligned sheets for every run.

| Key Point | Description |

|---|---|

| Introduction to DTF gangsheet builder | DTF printing needs consistency across growing orders; a gangsheet builder helps plan sheets to improve predictability and reduce waste. |

| What is a DTF gangsheet builder | A tool that combines design assets, color management, and layout logic to create gang sheets. |

| Design-to-sheet workflow steps | Import and standardize assets; color management and palette control; layout optimization; gangsheet design and variants; preflight and previews; export to printer-ready formats. |

| Why consistency matters | Consistent registration and color across orders reduce reprints, waste, and boost client satisfaction. |

| Key features that drive consistency | Centralized color management; precise layout controls; automated optimization; preflight checks; version control and reuse. |

| Best practices | Align with your printer’s capabilities; standardize color pipelines; plan for size and garment diversity; use alignment marks and test prints; document workflow. |

| Common pitfalls | Failing to account for real-world variation; overcrowding layouts; inconsistent asset preparation; ignoring post-press variability. |

| Practical implementation | Example: a multi-design collection with color-consistent palette, a single layout grid, and three gang sheets; preflight; export to printer-ready files. |

| Future trends | Automation, analytics, AI-assisted layouts, and cloud-based collaboration; part of end-to-end automation in the printing workflow. |

Summary

DTF gangsheet builder is a strategic asset for any operation seeking consistency in garment printing and reliable design-to-sheet workflows. By centralizing color management, optimizing layouts, and enforcing preflight checks, these builders help teams reduce waste, shorten lead times, and deliver predictable results across orders and campaigns. As the DTF landscape evolves, investing in a robust DTF gangsheet builder is a proactive step toward scalable, high-quality production that keeps customers returning for more.