DTF gangsheet builder is changing how shops maximize designs per sheet, cut waste, and accelerate production by turning complex layouts into streamlined, repeatable workflows. Used strategically, it aligns with DTF printing tips to improve throughput, reduce labor drift, and protect margins on growing product lines. By optimizing layouts and marrying item placement with printable areas, it supports digital transfer printing workflows while shortening heat-transfer times and reducing ink waste. The result is a smoother, more predictable workflow that helps you scale without sacrificing quality, enabling faster quotes, happier customers, and healthier margins. If you want to grow margins and win more repeat business, this approach offers a practical path forward for diverse shops.

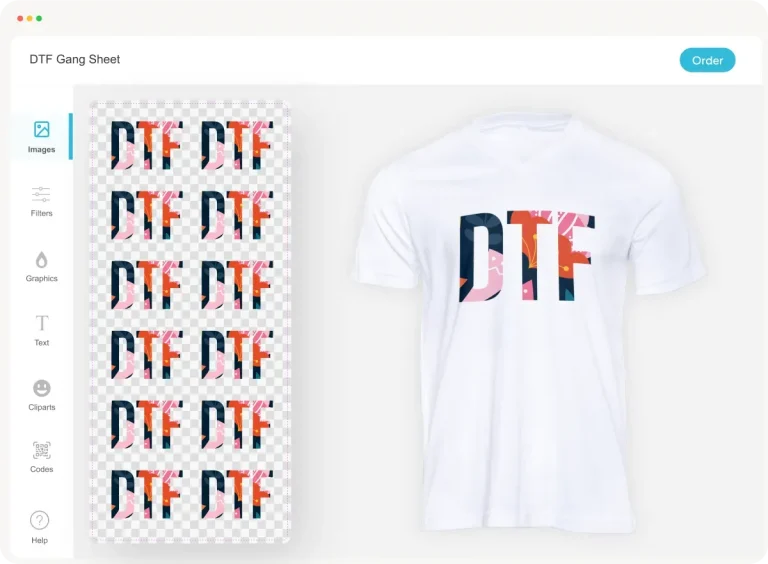

In plain terms, imagine a gang-sheet planning tool that automates how designs are arranged for multi-item transfers. This framing connects layout automation with broader ideas like print-flow optimization, batch-design efficiency, and inventory-aware scheduling. For teams working with direct-to-film transfers, the concept translates into a robust template system that minimizes waste while increasing output. Practically, the approach supports a cohesive pre-press routine, consistent color management, and tighter integration with production planning.

DTF Gangsheet Builder: Elevating DTF Printing Tips, Digital Transfer Printing, and Profitability

The DTF gangsheet builder is more than a layout tool—it’s a strategic core for improving DTF printing tips and overall digital transfer printing outcomes. By automating the arrangement of multiple designs on a single sheet, it reduces waste, speeds up setup, and enhances throughput, directly impacting DTF shirt printing profitability. When you can fit more designs per sheet without compromising quality, you gain clearer advantages in material utilization and per-unit costs.

This approach also strengthens DTF gang sheet efficiency by guiding optimal placement, color management, and consistent margins. With a well-tuned gangsheet workflow, you minimize ink waste, shorten heat transfer times, and reduce reprints, all of which align with cost-saving printing workflows. As you scale, the builder’s templates and batch planning become essential tools for maintaining predictable results across a growing catalog of designs and garment types.

Cost-Saving Workflows for DTF Shirt Printing Profitability and Efficient Gang Sheets

Achieving cost-saving printing workflows starts with thoughtful preparation: standardized templates, strategic design batching, and precise sheet layouts. By grouping designs by color families and garment types, you can minimize color changes and ink usage while maximizing sheet real estate. This directly boosts DTF printing efficiency and contributes to stronger DTF shirt printing profitability through faster turns and steadier margins.

Further gains come from integrating color profiles, bleed allowances, and automated pre-press checks into your production plan. Monitoring key metrics such as yield, ink consumption, and time per sheet lets you refine templates and layouts continually, delivering ongoing improvements in digital transfer printing precision and overall throughput. This disciplined, data-driven approach helps ensure each order meets quality standards while lowering waste and labor costs.

Frequently Asked Questions

How does a DTF gangsheet builder improve DTF gang sheet efficiency and DTF shirt printing profitability?

A DTF gangsheet builder automates the arrangement of multiple designs on a single sheet, maximizing DTF gang sheet efficiency and reducing waste. By optimizing placement, color management, and pre-press checks, it lowers ink usage and setup time in digital transfer printing, speeding production and improving per-unit margins. This supports cost-saving printing workflows and enhances DTF shirt printing profitability.

What practical steps can I take using a DTF gangsheet builder to reduce costs and optimize digital transfer printing workflows?

Start with templates for common garment sizes and placements; load designs into the gangsheet early to identify conflicts; consolidate palettes to reduce ink; let the gangsheet builder optimize the sheet layout; enforce color profiles to minimize reprints; automate pre-press checks; integrate gangsheet planning with inventory and production scheduling; print proofs before full runs; and monitor metrics like ink usage and waste to continuously improve cost-saving printing workflows in digital transfer printing.

| Aspect | Key Points |

|---|---|

| What is a DTF gangsheet builder and why it matters | Defines a gangsheet as a single layout grouping multiple designs on one sheet. A DTF gangsheet builder automates arrangement to maximize material use, affecting ink usage, heat transfer time, and units produced per run. It’s foundational to profitability in DTF shirt printing, reducing misprints and setup changes and enabling faster throughput and lower unit costs. |

| The economics of gang sheets | Material efficiency (minimized waste by tight packing and alignment with constraints); Time savings (fewer sheet swaps and reprints); Ink optimization (fewer color changes and better ink use); Labor efficiency (less time configuring jobs, more time printing) |

| Strategic tips to maximize savings (1–7) | 1) Start with template system: Create standard gang sheet templates for common sizes/configurations to reduce setup time and ensure consistent margins. 2) Plan designs in batches: Group designs by color families, garment types, or ink cost to optimize color management and minimize ink waste. 3) Optimize sheet layout: Arrange designs in blocks to maximize sheet area; prioritize high-demand/high-margin items and place less-critical designs in leftover spaces. 4) Manage color profiles and palettes: Consistent color management reduces corrections and reprints. 5) Consider margins and bleed: Account for margins, bleed, and transfer mask to prevent crop errors. 6) Automate pre-press checks: Use automated checks for alignment, color counts, and ink usage to minimize waste. 7) Integrate with inventory/production planning: Tie gang sheet planning to inventory calendars to reduce rush orders and improve margins. |

| Practical steps to implement | – Create standardized templates for common garment sizes (adult, youth, youthXS) and placements (chest, back, sleeve). – Load designs strategically: map new jobs into the layout early and resolve conflicts before printing. – Use color-limited palettes: consolidate to fewer colors to reduce ink and simplify curing. – Test on a small batch first: print a proof to verify color accuracy, alignment, and spacing. – Monitor results and adjust: track yield, ink usage, and time per sheet to refine templates and layouts. |

| Case study-style example: a small shop’s improved margins | Example: shop produces 200 shirts/week. Before: designs printed on separate sheets, ~2% waste, extra hours for alignment. After: four designs per sheet, waste |

| Common pitfalls to avoid | – Overloading sheets can cause misalignment/bleed. – Ignoring substrate constraints may require heat/dwell adjustments. – Underestimating early setup time. – Skipping post-print validation. – Failing to track metrics (ink, waste, throughput). |

| Tips for different shop sizes and goals | – Startups/small shops: focus on a few high-volume designs and perfect templates to validate quickly and scale. – Mid-sized shops: invest in color management and automation features; use batch processing for similar orders. – Established studios: optimize throughput with advanced templates, robust inventory integration, and real-time monitoring; pursue continuous improvement in profitability. |